23

KOOK 60 4.0 - KOOK 67 4.0 - KOOK 70 4.0 - KOOK 80 - KOOK 87 - KOOK 90 4.0

EN

12.2

IGNITION

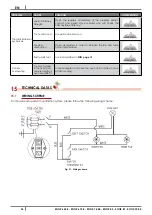

Fig. 51 - Kook 60 4.0 - Kook 70 4.0

Fig. 52 - Kook 80 - Kook 87 - Kook 90 4.0

LEGEND

Fig. 51 page 23 - Fig. 52 page 23

1

Secondary air regulator above door

2

Combustion air regulator

3

Ignition valve

4

Oven thermostat

5

Cooker side panel

6

Combustion chamber

7

Fan switch

8

Stainless steel top

9

Hot plate

10

Backsplash

11

Exhaust stub pipe

12

Stainless steel plinth

•

Place firelighters in the burning pot with small pieces of well-seasoned wood.

•

Light and if necessary keep the door open for a few minutes until the combustion chamber and flue start to

heat up.

Fig. 53 - Wood arrangement

Fig. 54 - Wood ignition

•

Open the regulator (1) above the door completely, the combustion air regulator (2) and the ignition valve

(3).