19

ATRIUM AT 5kW-ROXY-MADISON-SOLO-TABLA

Fig. 10 - Display: language

8.3.4 Menu M4 - STAND-BY

Allows you to enable or disable the M4 - Stand-by " M4 StAnd-by "mode (see 14366). Once the M4 menu has been selected with

the P3 button, press P1 (decreases) or P2 (increases) to change the state from ON to OFF and viceversa.

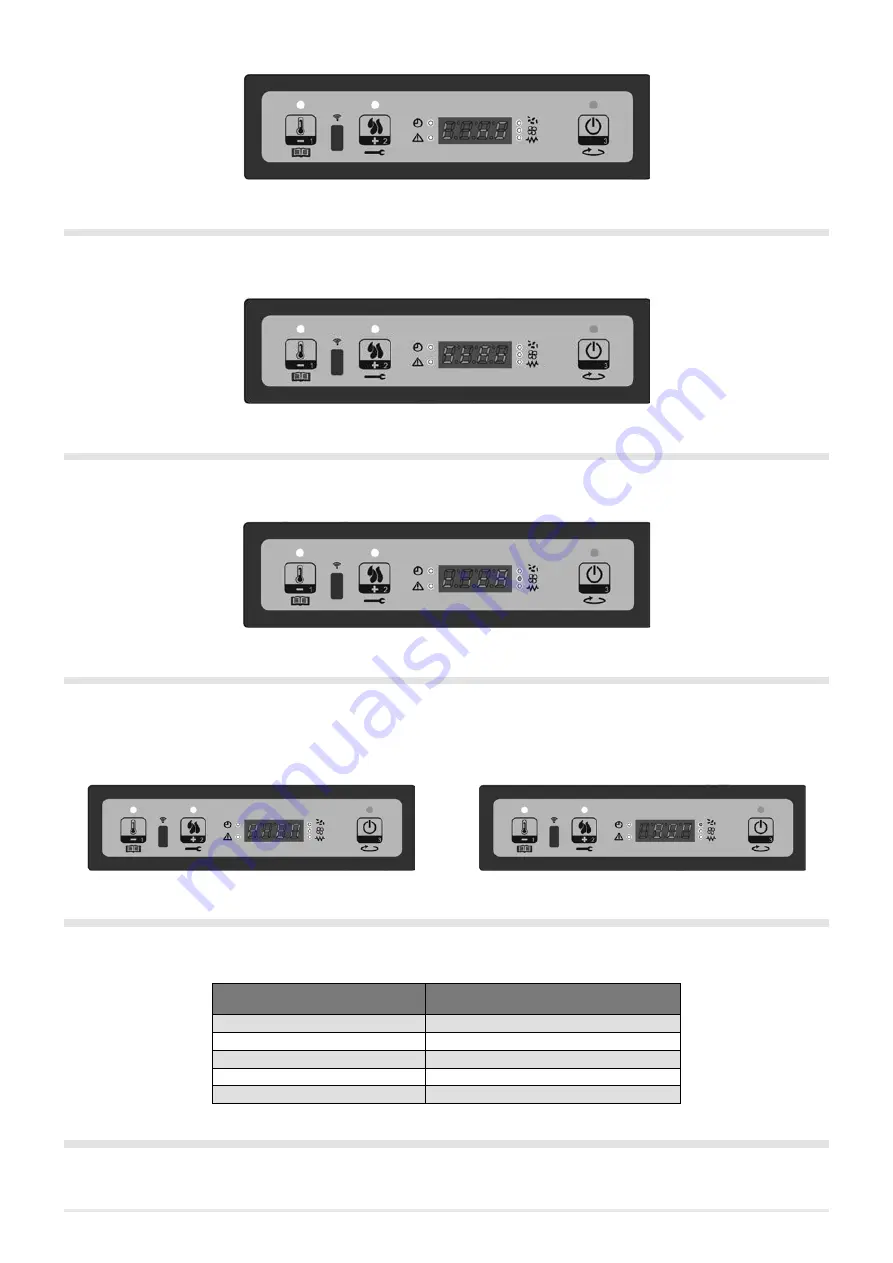

Fig. 11 - Display: stand-by

8.3.5 Menu M5 - BUZZER

Allows you to enable or disable the buzzer of the controller when alarms are indicated (see

). Enable or disable with buttons

P1 or P2, and confirm with P3.

Fig. 12 - Display: buzzer

8.3.6 Menu M6 - FIRST LOAD

This function is only available when the stove is OFF and allows the feed screw to be loaded with the first start-up of the stove,

when the pellet tank is empty. After selecting menu M6, the message

Press More

"

PrESS MorE

" will scroll on the display (see

). Then press P2 (increases). The flue gas fan turns on at maximum speed, the feed screw turns on (feed screw LED on) and they

remain until the time indicated on the display elapses (see

), or until button P3 is pressed.

Fig. 13 - Display: press more

Fig. 14 - Display: time left

8.3.7 Menu M7 - STOVE STATUS

Once in menu M7, after pressing button P3, the status of some variables scrolls on the display while the stove is working. The table

below shows an example of the display and its meaning of these values.

STATUS DISPLAYED

MEANING

3,1”

Pellet loading feed screw status

52’

Time out

Toff

Thermostat status

106°

Flue Gas Temperature

1490

Flue gas extraction speed

8.3.8 Menu M8 - ENGINEER SETTINGS

This menu item is reserved for the stove installer. After entering the password (see

) it allows you to set the various opera-

ting parameters of the stove using buttons P1 (decreases) and P2 (increases).

Summary of Contents for ROXY

Page 38: ...NOTE...

Page 39: ...NOTE...