79

Installation & Service Manual

Combustion Analysis Procedure

1. Turn the main power off to the boiler.

2. Remove the flue temperature sensor from the flue pipe

connection.

Note:

Combustion measurements will be

made at this point.

3. Insert the probe from a combustion analyzer into the

hole left by the removal of the flue temperature sensor.

4. Turn the main power on to the boiler.

5. Place the boiler into the active position by pressing the

UP button for five (5) seconds (see page 63).

6. Hold the ENTER key plus the UP button for five (5)

seconds to enter Service Mode.

7. Once the boiler has modulated up to full fire, measure the

combustion. The values should be in the range listed in

Table 13-5. The CO levels should be less than 150 ppm

for a properly installed unit.

If the combustion is not within the specified range,

reference Table 13-6 for possible causes and corrective

actions.

Table 3-6 Troubleshooting Chart - Combustion Levels

POSSIBLE CAUSE

CORRECTIVE ACTION

Vent/Air Intake Length

or Obstruction

• Refer to Section 3 - General Venting for the proper venting and air intake methods for the

Cadet heating boiler.

• Check for obstructions at the vent/air intake terminals.

Gas Supply Pressure

• Refer to Section 7 - Gas Connections for the proper gas supply for the Cadet heating boiler.

Dirty/Damaged Burner

• Refer to page 66 of this manual for burner removal.

• Replace burner if necessary.

Gas Valve Adjustment

• Refer to this page of the manual for the gas valve adjustment procedure.

13

Troubleshooting

(continued)

Table 13-5 Flue Products

Natural Gas

Propane

CO

2

O

2

CO

2

O

2

8.0% - 10%

3.0% - 6.5%

10.0% - 11%

4.1% - 5.4%

You must replace the flue gas temperature

sensor to prevent flue gas spillage into the

room. Failure to comply could result in

severe personal injury, death, or substantial

property damage.

WARNING

Gas valve adjustment procedure

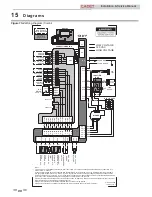

Locate the throttle adjustment screw on top of the gas valve,

see FIG. 13-2. Using a screwdriver, turn the screw a 1/4 turn

counterclockwise

to increase CO

2

levels or a 1/4 turn

clockwise

to decrease CO

2

levels. After one adjustment on the valve,

follow the Combustion Analysis Procedure to measure the

combustion.

If combustion is still not within the specified range, repeat

the procedure. This procedure SHOULD NOT be performed

more than four (4) times. If after four (4) adjustments and the

combustion is still not within the specified range, revisit the

possible causes in Table 13-7 or replace the gas valve.

IMG00262

THROTTLE

ADJUSTMENT

Figure 13-2 Gas Valve Adjustment

8. Once the combustion analysis is complete, test the safety

shutoff device by turning the manual shutoff switch to

the OFF position and ensuring that the boiler shuts

down and registers an alarm. Turn the manual gas valve

to the ON position and reset the control.

9. Turn the main power off to the boiler and replace the flue

temperature sensor into the flue pipe connection.

10. Place the boiler back into normal operation.