Doc150313-01

Installation and maintenance manual

www.cadexair.com

6

1010, Boulevard Lionel Boulet

1-800-461-0668

Varennes, Québec, Canada J3X 1P7

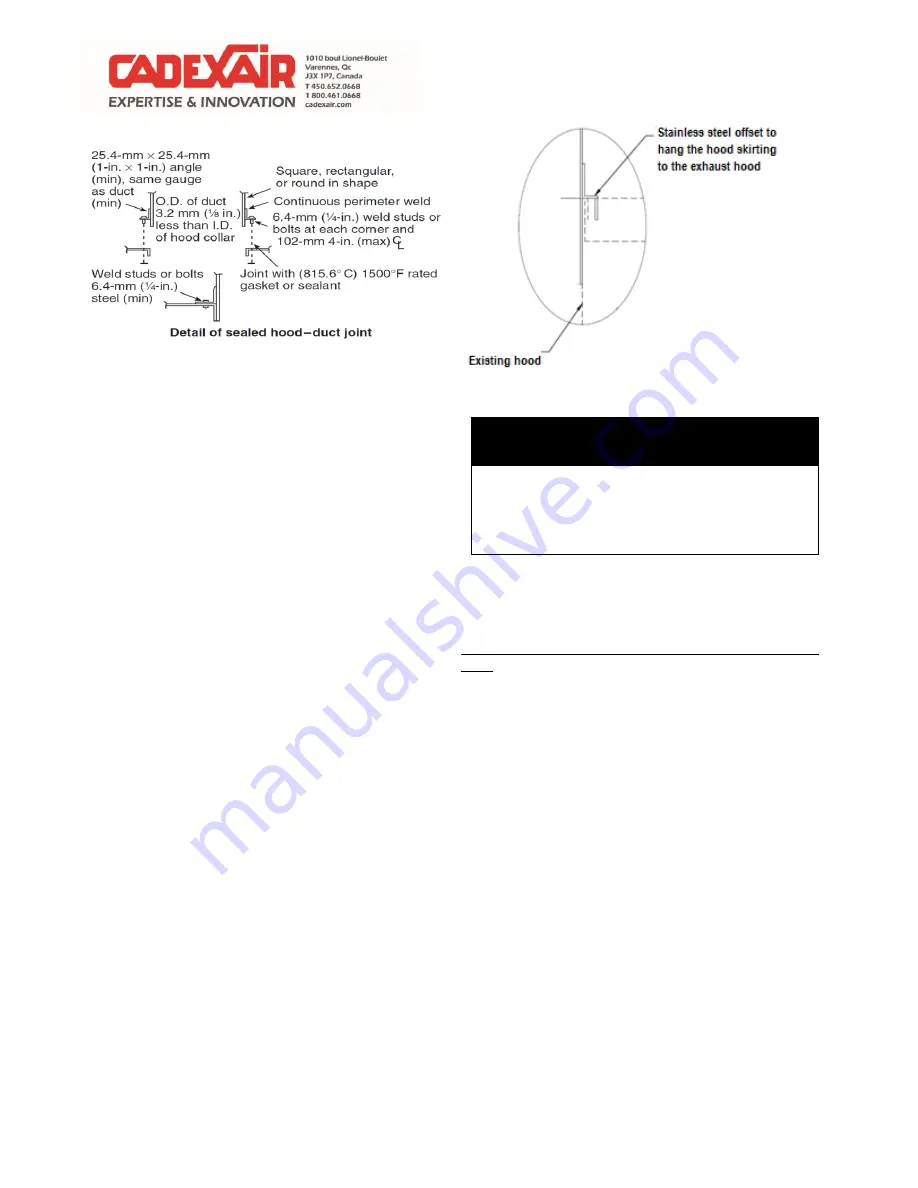

It is possible to connect the kitchen exhaust hood collar

according to the following figure from NFPA96.

Exhaust hood collar joint and air supply collar joint

on PE series

Type 2, C3 series exhaust hood are note regulated by

NFPA 96 standards. A welded duct is not mandatory.

The junction can be soldered by point to intervals from

1 to 2 inch (25 to 50 mm) or with metal screws every 3

to 6 inch (75 to 150 mm).

Self-cleaning hood CA1M series plumbing fitting

Self-cleaning hood series are equipped with a NPT

type 3/8 brass fitting for each hood section. CA-W

exhaust hood series are equipped with 2 connections.

Single and double hoods will be provided with a

connection for a 2 inch male NPT drain.

Electrical wiring

Hoods are frequently equipped with lighting.

Depending on the product, the lighting is pre-wired by

hood section to a junction box. Certain model

requires that each fixture to be connected. Refer to

the schematic of this control provided on the

manufacturing plans to ensure that the wiring is done

properly.

Access on top of exhaust hoods

Provide an access on top of the hood to perform

maintenance, electrical wiring and access control

components, plumbing fittings, and fire suppression

system components even after the installation and

construction is completed.

Exhaust hood skirting

It is possible to install a hood skirting provided by

Cadexair or not above the hood. The installation

method may vary according to the exhaust hood

model. The hood skirting can be installed with a “Z”

component installed on the back panel of the hood

skirting. Depending on the height of the hood skirting,

tracks or any other methods might be necessary to

support the hood skirting. An assembly with screws

allow keeping corners together.

IMPORTANT

Never pierce the hood for installation of

hood skirting, suspended ceilings or

other. This will void the exhaust hood

homologation

Silicone usage

Once the exhaust hood is in place, it is recommended

to apply a silicone joint between different hood

sections or between the exhaust hood and walls.

Recommended silicone: Kason RubbaSeal, aluminum

color

Seismic performance

It is the buyer’s responsibility to perform a seismic

installation according to plans provided by a seismic

specialized engineer.

Fire suppression system

According to NFPA 96, a fire suppression system is

mandatory with this type of hood above cooking

equipment for the exhaust ducts and cooking

equipment. This system is activated by fusible links or

thermal detectors integrated to the exhaust hood. In

case of fire, the air exhaust is maintained and the air

supply is stopped. Filters housing, exhaust collar and

cooking surface are sprayed with a chemical product.

Energy sources like gas and electricity are interrupted

for the cooking equipment and hood lightings and an

alarm system sounds.