TR-MAN-4500-A

Operator's Manual - 4000M 4500M

Page 38 of 46

Required Maintenance

Prevention of mechanical failure is the goal of any good maintenance schedule. The

secret to preventing unwanted down time is to adhere to a maintenance schedule

suited to the way you use the equipment. Your maintenance schedule should include

the following minimum requirements:

Maintenance must be done ONLY when the machine is shut down and

is in a non-loaded condition. This means that no fluid is being

pumped through the reel and all mechanical and hydraulic tension has

been released from the hose rewind system and stabilizers.

Each Use

Maintenance Item

Figure

Procedure

Visually inspect equipment

N / A

Walk around the unit and inspect for loose, missing

or damaged items. Check the condition of the

indexer drive button, chains and connecting links.

Replace missing or damaged items and tighten

loosened items.

Maintain the tire pressure at

36-40 psi (248-276 kPa)

N / A

Using a tire pressure gauge, check the pressure of

each tire and add or remove air to achieve the

desired pressure.

DO NOT LOWER TIRE PRESSURE

BELOW THE RECOMMENDED LEVEL.

A lower pressure than the

recommended pressure will result in

the tire separating from the rim.

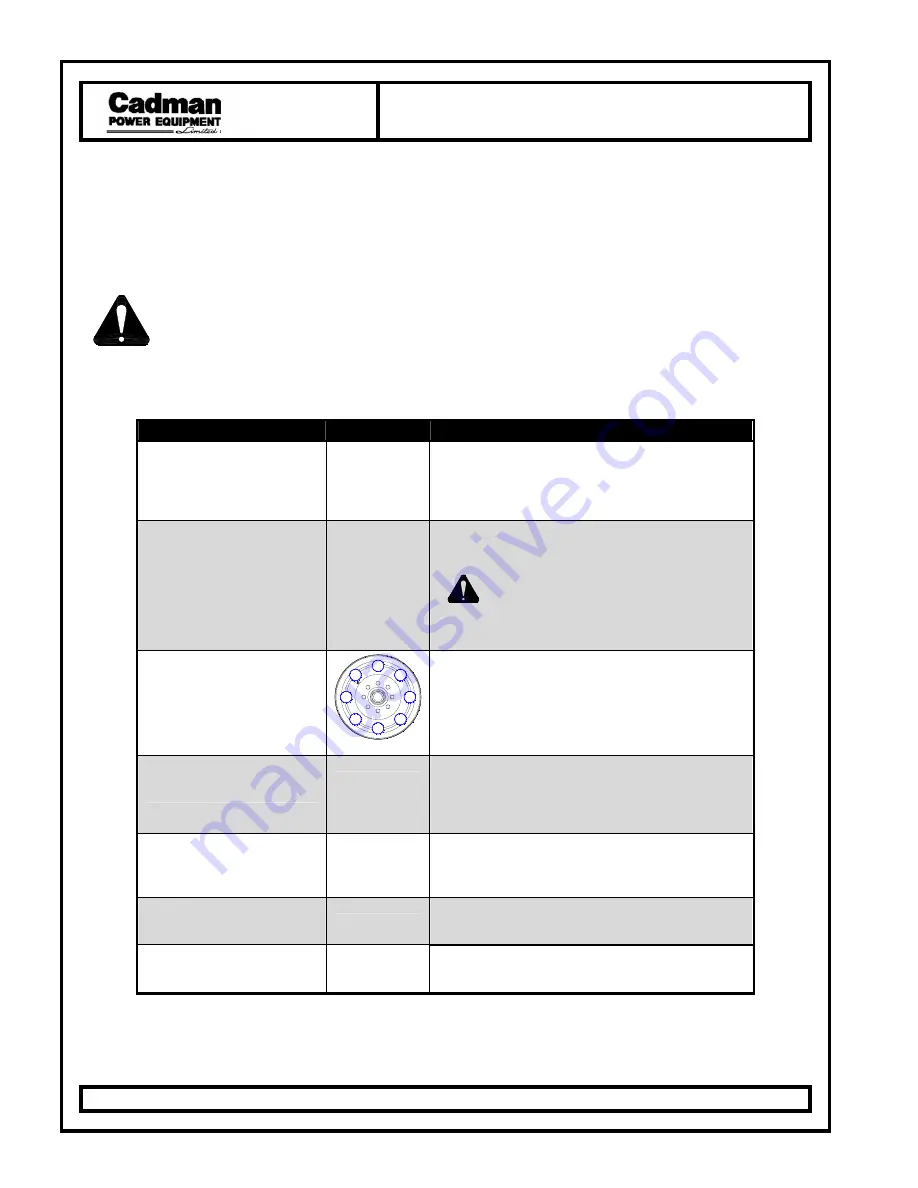

Tighten all wheel bolts

1

8

4

6

2

7

3

5

img-00132.wmf

Before moving the unit, verify that the wheel bolts

are tight. When tightening the lug nuts use the star

pattern with your torque wrench set at

110 ft/lbs (150 N.m).

Adjust, if necessary, the

alignment and tension of the

drive chains

Figure 22

The drive chains (around the drum) are properly

tensioned when it has no visible slack and is

seating properly onto the drive pegs when the drum

rotates. Adjustments are made by turning the

locknut (3/4” wrench) on the spring adjustment rod.

Check the oil level in the

indexer gearbox

Figure 21

Remove the oil plug (hex plug) on the side of the

gearbox. The oil should be level with the bottom of

the plug hole.

(refill capacity = 350mL (12 oz.) approximately)

Lubricate the indexer drive

button and slide rails

Figure 20

Liberally apply acceptable grease along the length

of the slide rail and around the drive button.

(See Lubricants)

Lubricate all grease fittings

Figure 23

Using a grease gun, lubricate each grease fitting

with an appropriate amount of acceptable grease.

(See Lubricants)

Table 1 - Required Maintenance - Each Use