12

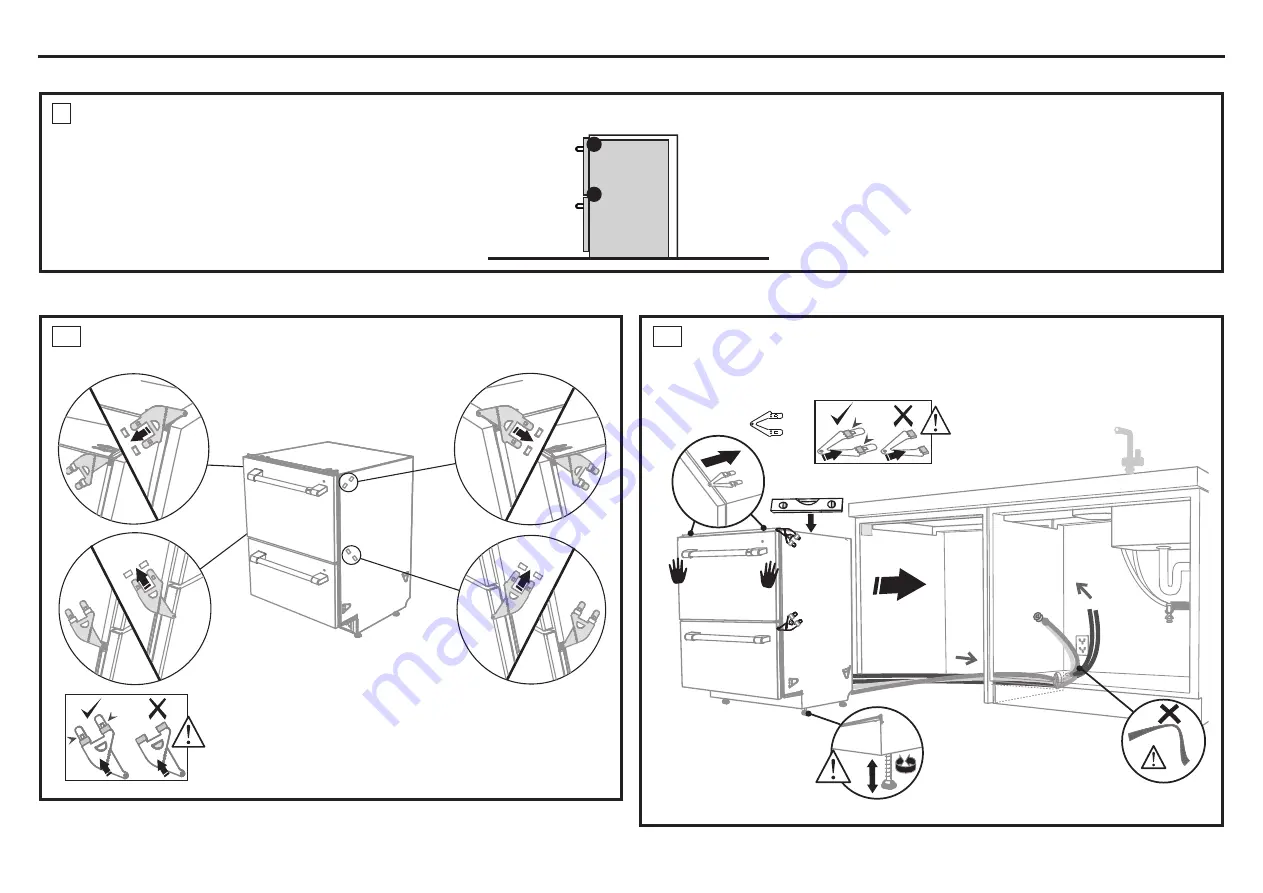

Clip all four side mounting brackets

into their slots using a flat-bladed

screwdriver. Ensure they’re securely

fitted before sliding product into cavity.

The mounting slots are in pairs, one on

each side diagonally across the product.

A

bracket must match

A

slot and

B

bracket

must match

B

slot.

When fitting brackets, ensure the

ends are not pushed down into the

chassis.

A

A

A

B

B

B

A

B

(x2)

As you push product

in, pull through hoses

and cord, ensuring

they don’t get kinked

or twisted.

Optional - Attach the

two top mounting

brackets

Initially level the product

When fitting brackets,

ensure the ends are not

pushed down into the

chassis.

You can raise or lower the

product by twisting the

feet. Then take care when

pushing the product into

the cavity that you do not

bend the feet.

Installation Instructions

A2

PULL HOSES THROUGH AND PUSH UNIT INTO THE

CAVITY

A1

ATTACH SIDE MOUNTING BRACKETS

CHOOSE WHICH INSTALLATION METHOD (A) OR (B) IS MOST SUITABLE FOR YOUR CABINETRY

A

RECOMMENDED METHOD (A) - SECURE WITHOUT DRAWER REMOVAL (FRAMELESS CABINETRY ONLY)

OPTION A - RECOMMENDED

Summary of Contents for CDD420P2TS1

Page 22: ...22 Notes...

Page 23: ...23 Notes...

Page 24: ...24 Printed in Thailand 31 4000257 Rev 0 11 21 GEA 518862...