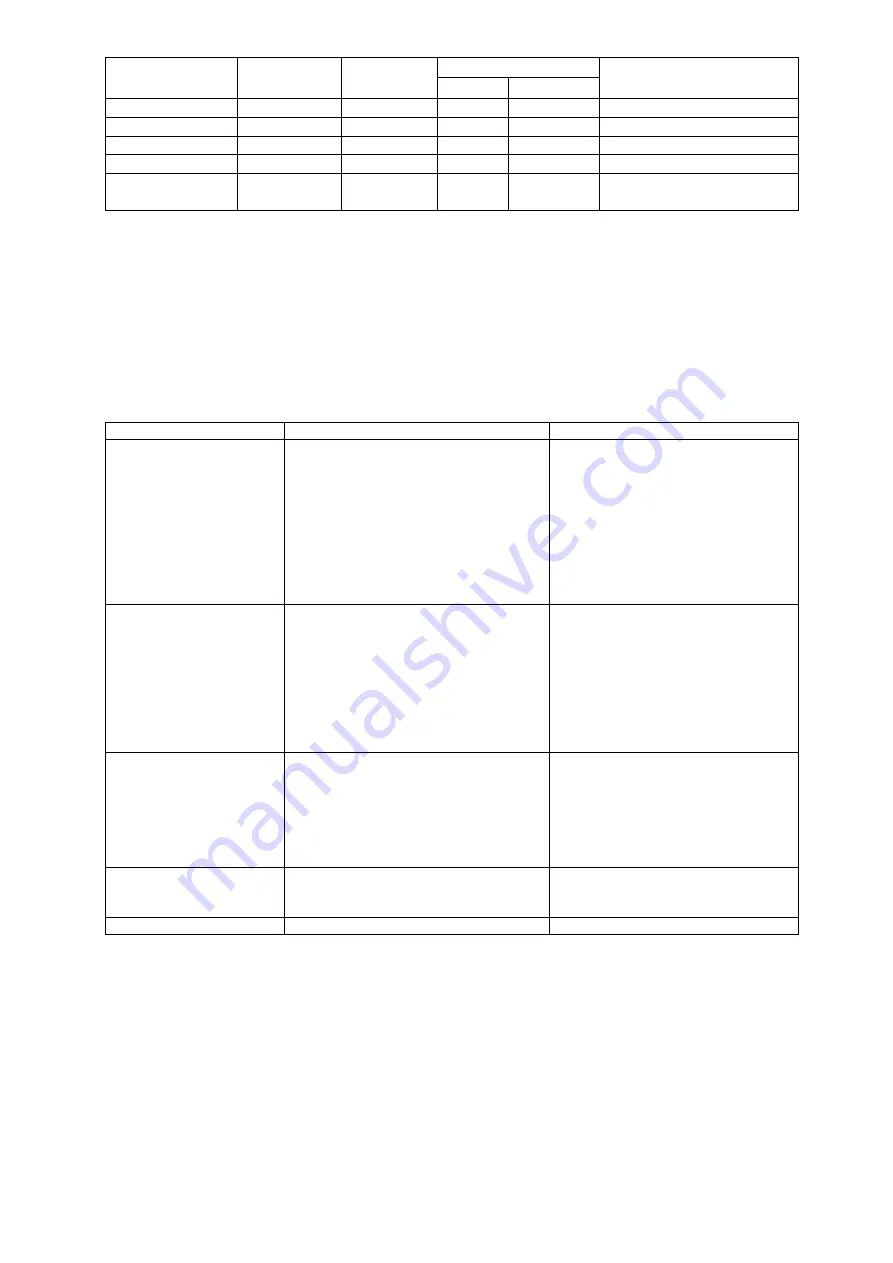

11

Between

and

Model

Fastening torque

Notes

[

kgm

]

[

Nm

]

BODY

PORT

LIB-2”

0,2

2,0

Tightens the valve

SUPPORT

BODY

LIB-2”

2,5

25

Tightens the diaphragm

CONNECTING ROD

PLATE

LIB-2”

0,9

9

REDUCER

SUPPORT

LIB-2”

9,38

92

COVER

BODY

LIB-2”

1,13

11,1

Tightens cover and reducer

carter

15. DISPOSAL

In case of demolishing the machine or placing it out of service, differentiate the parts according to the

manufacturing materials and dispose of them complying with the current Standards in the country where

demolition or placing out of service takes place.

16. TROUBLESHOOTING

MALFUNCTIONING

POSSIBLE CAUSE

SOLUTION

The pump works but does

not supply

1.

Excessive suction height.

2.

The suction piping is not airtight.

3.

Blocking of the pump

4.

The suction pipe is not fully

submerged inside the liquid to be

pumped.

5.

The suction filter is blocked

6.

The suction and/or delivery valves

have remained in open position for

the presence of a solid body

1.

Reduce the suction height.

2.

Restore seal of all gaskets of the

piping.

3.

Remove any blocking bodies

inside the pump.

4.

Fully submerge the suction pipe

so it does not suck air.

5.

Clean the suction filter

6.

Remove the solid body

Low flow rate

1.

The rotation speed is too low.

2.

The delivery pipe is undersized or

blocked

3.

Too many curves or delivery pipe

too long

4.

Use of non-reinforced collapsible

sleeve

5.

Damaged pipes

1.

Increase engine rotation speed, if

possible.

2.

Replace the pipe or clean it.

3.

Amend the delivery line

4.

Shorten or install a reinforced

pipe

5.

Replace

Excessive noise

1.Damaging of reducer

of speed

2.The pump is not safely fastened to the

parking stand

3.Suction is blocked

1. Repair of reducer by means of

intervention of staff authorised by

the Manufacturer

2. Ensure the parking stand is blocked

by means of the fixing pin with

insertion of the safety pin

3. Clean piping

There is water above the

diaphragm

1.

The diaphragm is broken

2.

The screws tightening the

diaphragm are loose

1.

Replace the diaphragm

2.

Tighten the screws

…

…

For the functioning defects of the supply motors see the attached instruction manuals.