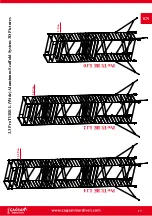

6. Place the 4 cross connection parts

to the modular frames you just pla-

ced. Make sure the aluminum cast

clamps are safely seated and locked.

(Drawing 9)

7. Then carry it upwards onto the 7th

step of the 2nd floor and fix it. Don’t

forget to open the wind lock while di-

sassembling the platforms. After this

your scaffold will rise for another flo-

or (Drawing 10)

9

10

22

EN

Summary of Contents for ProTUBE F

Page 35: ... ...