2

0

English

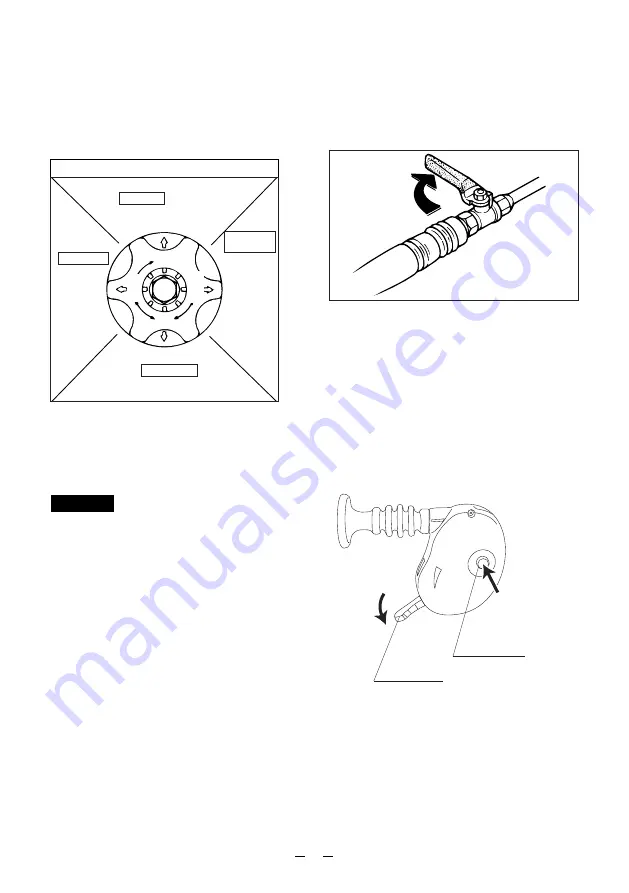

Handle of pressure control valve

STARTING

①

When engine is started and

when pump starts suction.

HERBICIDE

When low-

pressure spray

is required.

(Spray of weed

killer, etc.)

HIGH

PRESSURE

①

When high

pressure is

required in

particular.

②

When this

machine is

set at a fixed

position and

longer hose

than

standard is

used.

INSECTICIDE

Normal spraying work

Operation

Turn the handle of the pressure control

valve until there is sufficient pressure for

work such as spraying weeds (fixed

1

Close ball cock.

1

After confirming proper pump and spray

operation in the machine, move the throttle

lever to high-speed position.

2

When opening ball cock, chemicals will be

sprayed from nozzle in a mist.

3

(fixed position)

・

When setting the pressure control valve handle

to "INSECTICIDE", "HERBICIDE" with throttle

fully open at the "HIGH PRESSURE" position of

pressure control valve handle, engine

revolutions increase as pressure decreases.

When using this machine at the "INSECTICIDE",

"HERBICIDE" position, use at a position little bit

back from full open throttle.

CAUTION

Stop

Return throttle lever to low speed.

2

Push stop button to stop engine.

3

H

L

Push

Throttle lever

Stop button

STARTING

HERBICIDE

HIGH

PRESSURE

INSECTICIDE

Summary of Contents for Fog King PS25

Page 1: ...FOG KING PS25...

Page 2: ...RUS 1 1 2 3 4 5 6 7 9 10 10 11 11 12 Caiman 1...

Page 3: ...RUS 2 2009 128 21 2009...

Page 5: ...1 2 3 1 2 3 4 15 3 101 0047 29 141408 0 8 Fog King PS25 2017 4...

Page 6: ...1 2 5...

Page 7: ...1 2 25 2 1 6...

Page 9: ...H L 2 1 1 2 3 3 STARTING HERBICIDE HIGH PRESSURE INSECTICIDE 8...

Page 10: ...Caiman 0 6 0 7 0 6 0 7 1 2 3 9 15 20...

Page 11: ...STARTING 1 2 3 4 10 Caiman 1 2 3 4 1 2 3 4 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8...

Page 12: ...20 150 30 1 12 1 12 3 10 11 2011 924 10 04 2012 08 693 11...

Page 13: ...1 2 3 10 483 438 30 10 12...