2

1

English

Maintenance

Cleaning, maintenance and draining

For cleaning, check and maintenance, always be

sure to stop machine.

Check and maintenance items

for each season

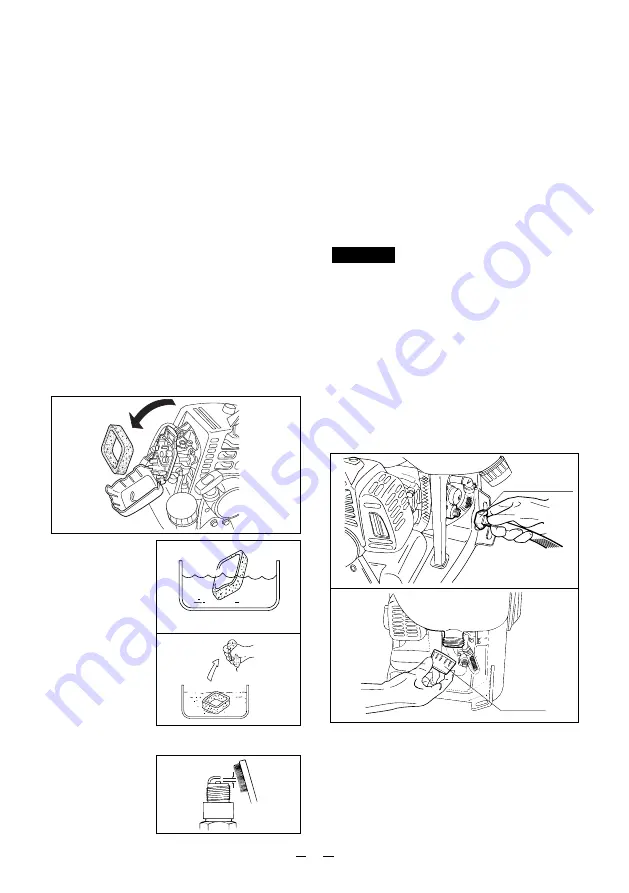

Cleaning of air cleaner

・

When elements become dirty or clogged,

reduced performance or difficulty starting is

observed. Clean the elements regularly to

remove dirt and prevent clogging.

・

When cleaning the element, wash it using gaso-

line, dip it in the blended fuel used and install it

after squeezing it hard to remove excess fuel.

Pump

Check for worn piston packing and seal packing,

and replace worn one with new one.

※

For disassembly and maintenance, consult with

the sales outlet where you purchased the prod-

uct or sales office.

Drain

Make sure to drain, otherwise the pump might be

damaged by freezing in winter.

①

Remove drain cap of chemical tank and hose

connecting screw of pump to drain residual liquid.

②

Put fresh water into the chemical tank, start

the engine, spray from the nozzle to clean the

pump and inside of the hose.

③

Operate for 15-20 seconds to drain residual

liquid at the throttle lever position, which is a

little bit back from full open position.

④

Set throttle lever at low speed, and stop the

engine with the stop button.

CAUTION

Disassembly

1

Clean

2

Squeeze

3

Cleaning ignition plug

・

Remove car-

bon, and adjust

the clearance

to 0.6-0.7mm.

0.6~0.7mm

Hose contacting screw

Drain cap

Dip in the

blended fuel

Squeeze

hard

Gasoline

Remove

carbon

Summary of Contents for Fog King PS25

Page 1: ...FOG KING PS25...

Page 2: ...RUS 1 1 2 3 4 5 6 7 9 10 10 11 11 12 Caiman 1...

Page 3: ...RUS 2 2009 128 21 2009...

Page 5: ...1 2 3 1 2 3 4 15 3 101 0047 29 141408 0 8 Fog King PS25 2017 4...

Page 6: ...1 2 5...

Page 7: ...1 2 25 2 1 6...

Page 9: ...H L 2 1 1 2 3 3 STARTING HERBICIDE HIGH PRESSURE INSECTICIDE 8...

Page 10: ...Caiman 0 6 0 7 0 6 0 7 1 2 3 9 15 20...

Page 11: ...STARTING 1 2 3 4 10 Caiman 1 2 3 4 1 2 3 4 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8...

Page 12: ...20 150 30 1 12 1 12 3 10 11 2011 924 10 04 2012 08 693 11...

Page 13: ...1 2 3 10 483 438 30 10 12...