4

Portable Spa Site Preparation

Your spa needs a solid and level foundation. The area that it sits on must

be able to support the weight of the spa, with water and the occupants who

use it. If the foundation is inadequate, it may shift or settle after the spa

is in place, causing stress that could DAMAGE YOUR SPA SHELL AND

FINISH.

Note: Damage caused by inadequate or improper foundation support is

not covered by the warranty. It is the responsibility of the spa owner to

provide a proper foundation for the spa.

Place the spa on an elevated foundation (preferably a 3” - 4” concrete

slab). Pavers, gravel, brick, sand, timbers or dirt foundations are

not

adequate to support the spa. If you are installing the spa indoors, pay

close attention to the flooring beneath it. Choose flooring that will not be

damaged or stained.

If you are installing your spa on an elevated wood deck or other structure, it

is highly recommended that you consult a structural engineer or contractor

to ensure the structure will support the weight of 150 pounds per square

foot.

To properly identify the weight of your new spa when full, remember water

weighs 8.33 lbs. per gallon. For example, an average 8’ spa spa holds

approximately 500 gallons of water. Using this formula, you will find that

the weight of the water alone is 4,165 lbs. Combined with the dry weight

of the spa you will note that this spa will weigh approximately 5,000 lbs.

when full of water.

Note: It is strongly recommended that a qualified, licensed contractor

prepare the foundation for your spa.

Your Cal Spas

®

retailer can help you with your foundation and more. Your

retailer has a wealth of information and experience about how to get the

most out of your spa and can provide you with a full line of accessories

that are designed to complement your spa and increase your enjoyment.

In-Ground Spa Site Preparation

Ensure there is enough room for the spa and equipment.

•

The equipment pack must be located within a maximum of 15 feet

•

from the spa.

Plan for proper electrical and gas service to both the equipment area

•

and spa side.

Ensure the required flat, level foundation can be constructed in the

•

area chosen.

Summary of Contents for Avalon A726B

Page 1: ......

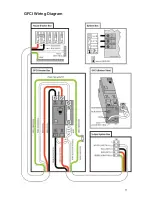

Page 13: ...11 GFCI Wiring Diagram...

Page 17: ...15 RCD Wiring Diagram...

Page 18: ...16 Installing the In Ground Shell...

Page 20: ...18...

Page 26: ...24...

Page 31: ...29...