2-56 x ½” SH

Plastic Ride Height

Spacers 3, 4, 5mm

Delrin

Pivot Ball

CRC Pro-Strut

Front End

2-56 Red

Locknut

4-40 x 7/16”

Red FH

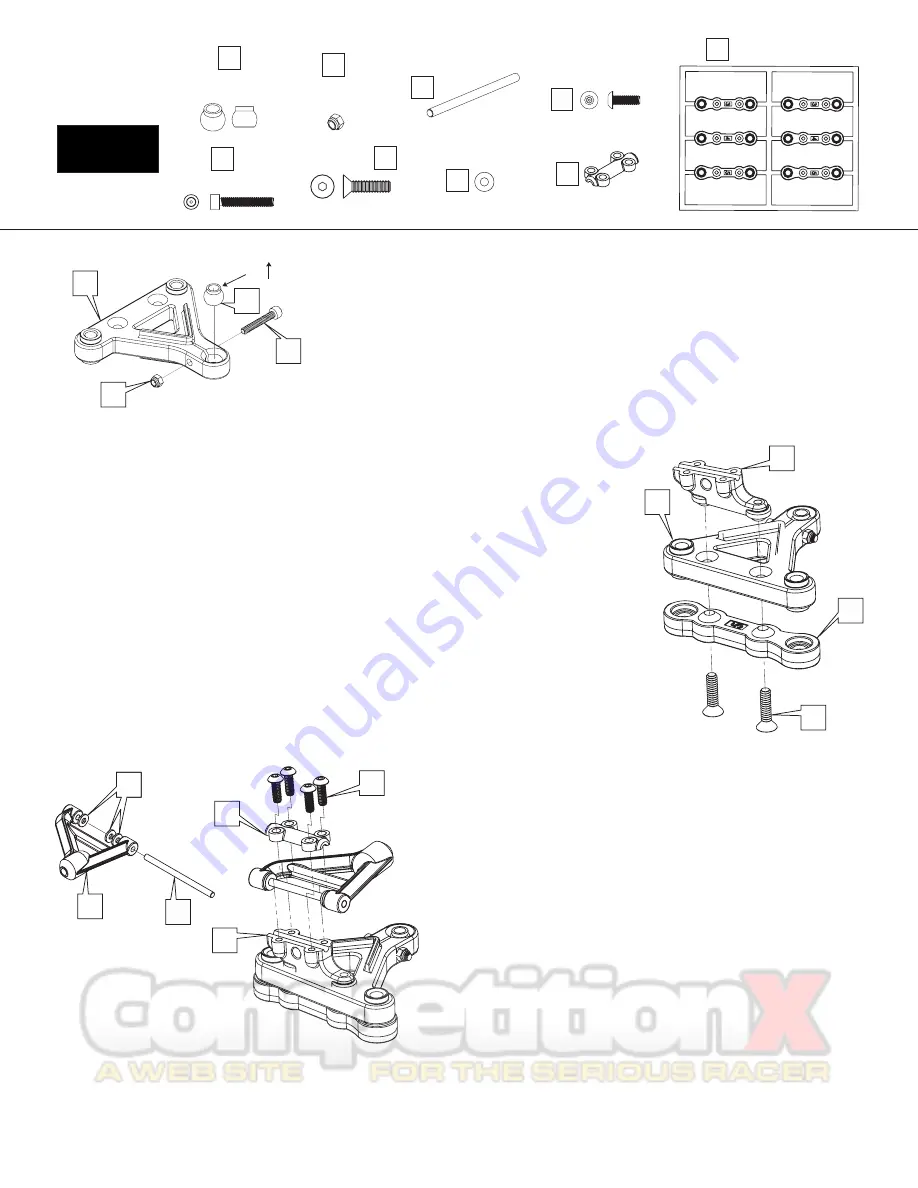

1 - Pop the delrin pivot ball [49] into the lower arm [50]. Place the arm on a strong table and push

the ball in with the back of screwdriver handle. Or preferably, you can use CRC’s 4279 Ball popper

pivot ball tool. Notice the “lip” of the delrin pivot ball is pointing upward. The diagram to the left

represents a right side lower arm. For the left side, flip the second arm over and be sure the pivot

ball is installed with the lip again facing up.

2 - Once the ball is popped in, insert the black 2-56 clamp screw [51] through the horizontal hole in

the lower arm. Thread the 2-56 red locknut [52] onto the black screw. Tighten the screw slowly

continuously checking the pivot ball. When it begins to bind a bit, back the 2-56 screw off a bit. The

ball should be free to pivot with just a bit of drag. There is no need to have this ball super loose and

free, a slight drag will be just the right amount of clamping force.

Check this fit after a few runs as the ball will wear and require additional clamping force.

Lip

1 - Install the upper A-arm mount [53] with the amount of Dynamic Caster desired. The options are 0, 5 and 10

degrees. The part shown to the right in the diagram is the 5 degree version and is a good starting point. The

10 will angle down more toward the front of the car with the 0 being parallel to the chassis. The general

thought is the more Dynamic Caster, more steering the car will have at corner entry.

2 - With side cutters or good scissors, cut off (do NOT break off) the 3, 4 and 5 mm spacers [54] from the ride

height tree. Use the 5 mm thickness for 1/10th scale tires. For fine front ride height adjustments, use the CRC

#4262 optional front shim set. This set contains .010, .020 and .030” plastic ride height shims. After selecting

the proper spacer, push the red 4-40 x 7/16” screw [55] through the plastic ride height spacer [54], then

through the lower arm [50], and then thread the screw into the upper A-arm mount [53]. Be sure NOT to over

tighten. Just snug, you are threading an aluminum screw into the plastic upper A-arm mount.

49

49

50

51

51

52

52

53

54

55

54

50

55

Bag F

10

1 - Break the mold tree from the upper A-arm [56]. You can clean up the

mold gates with a hobby knife or rotary tool.

2 - Locate the upper arm hinge pin [57] and slide it into one half of the upper

arm. Locate 3 small caster shims [58]. Push the hinge pin through the 3

shims. Then continue to push the hinge pin all the way into the upper arm.

3 - Now, install the arm/pin/washer assembly onto the upper arm mount [53].

Put the hinge pin in the channel. At this point you can set your starting

caster setting by moving these washers forward and back. The position

shown to the left will result in a competitive handling. Moving them to the

rear will increase steering from the center and exit of the corner.

If the fit of the upper arm is tight, trim the upper arm mount SLIGHTLY with a

hobby knife.

4 - Install the upper cap [59] with 4 black 2-56 button head screws [60]. The

topper is the “clamp” for the hinge pin. Be sure to tighten so that any gap is

gone, however, do not tighten beyond that point as damage can occur to the

upper a-arm mount holes.

56

57

58

53

59

Hinge Pin

57

Caster Shim

58

2-56 BH

60

Upper Cap

59

60