Summary of Contents for 142

Page 1: ...CalComp Model 140 Model 142 Floppy Disk Drives Technical Manual...

Page 11: ......

Page 19: ......

Page 64: ......

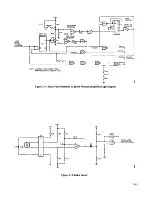

Page 70: ...16 20 21 32 F JgUIe 5 1 Model 140 and 142 DISk Drive Unit Sheet 2 of 2 Ii 29...

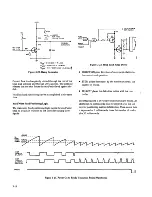

Page 75: ...17 5 23 Figure 5 2 Cone Lift Cover Assembly 5 9...

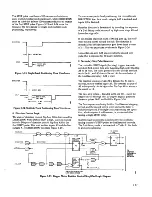

Page 79: ...13 21 ____ 24 3 2 i Figure 5 4 Data and Control Board Assembly VR49 5 13...

Page 83: ...21 i ro r 136 VR66 G J 3 2 1 Figure S 4A Data and Control Board Assembly VRS6 5 17...

Page 87: ...3 2 Figure 5 4B Data and Control Board Assembly VR57 5 21...

Page 91: ...13 21 24 3 2 Figure S 4C Data and Control Board Assembly VRS8 5 25...

Page 95: ...3 2 1 Figure S 4D Data and Control Board Assembly VR60 5 29...

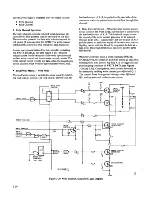

Page 103: ...11 c ell o 1 5 2 Figure S 4F Data and Control Board Assembly VR83 20 23 o o 5 37...

Page 109: ...California Computer Products Inc 2411 W La Palma Anaheim CA 92801...