U

ser

'

s

G

Uide

— 49

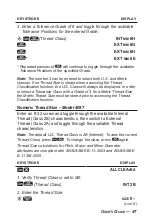

KeYSTROKe

DISPLAY

g *

ALL CLeAred

1. Verify Thread Class is set to 2B:

g b

(Thread Class)

INT 2b

2. Enter the Thread Size:

1 / 4 t

SIZe

1/4 –

INCH

3. Enter the TPI and store the final Thread Size:

2 8 t

THReD

SIZe

1/4 –

28

INCH

4. Find the available Internal Thread characteristics:

t

(Cut Tap Drill Size)

TAP

DRILL SIZe

3

t

(Roll Tap Drill Size)

R-TAP

DRILL SIZe

5.9

MM

t

(Close Fit Drill Size)

CLOSe

DRILL SIZe

f

t

(Free Fit Drill Size)

fRee

DRILL SIZe

H

t

(Min. Internal Pitch Diameter)

PTCH-

SIZe

0.2268

INCH

t

(Max. Internal Pitch Diameter)

PTCH+

SIZe

0.2311

INCH

t

(Min. Internal Minor Diameter)

MINR-

SIZe

0.2110

INCH

t

(Max. Internal Minor Diameter)

MINR+

SIZe

0.2200

INCH

t

(Min. Internal Major Diameter)

MAJR-

SIZe

0.2500

INCH

5. Switch to Thread Class 2A and find the available External

Thread characteristics:

g b b

(Thread Class)

eXT 2A

t

THReD

SIZe

1/4 –

28

INCH

t

(Rod Size for Thread Cutting)

ROD

SIZe

0.2500

INCH

t

(Rod Size for Cold Forming)

CfORM

SIZe

0.2283

INCH

t

(Max. External Pitch Diameter)

PTCH+

SIZe

0.2258

INCH

t

(Min. External Pitch Diameter)

PTCH-

SIZe

0.2225

INCH

t

(Max. External Major Diameter)

MAJR+

SIZe

0.2490

INCH

t

(Min. External Major Diameter)

MAJR-

SIZe

0.2425

INCH

t

(Max. External Minor Diameter)

MINR+

SIZe

0.2065

INCH