P

ocket

R

efeRence

G

uide

—

29

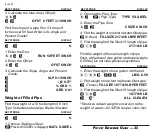

1. Enter Pipe Size:

6

STD SIZE 6 INCH

2. Change the default Welder’s Gap from

1/8” to 3/32”:

2

*

GAP 0-3/32 INCH

3. Enter Offset:

2

4

OFST 24 INCH

4. Enter the advance:

2

(Advance)

RUN 32 INCH

5. Enter the Roll and calculate the pipe

length and unknown bend angle:

1

(Roll)

LNTH 42-1/16 INCH

CUT 35-1/4 INCH

TO 3-5/16 INCH

GAP 0-3/32 INCH

FIT° 40.46°

IARC 4-1/32 INCH

CARC 6-11/32 INCH

OARC 8-11/16 INCH

*

Setting welder's gap to 3/32 inch will

temporarily set the outputs to 1/32 fractional

resolution. To keep outputs in their current

1. Enter Offset:

1

7

OFST 17 INCH

2. Enter the advance:

2

(Advance)

RUN 28 INCH

3. Enter the Roll and calculate the pipe

length and unknown bend angle:

6

1

2

(Roll)

LNTH 33-3/8 INCH

FIT° 33.02°

Continue pressing the

key to view all

related values.

Rolling Offset – Cut Length

Find the end-to-end pipe length for a rolling

pipe offset with a 13” Roll, a 24” Offset,

and an advance of 32”. The bend angle is

unknown. This example assumes 6” Steel,

factory made long radius butt weld elbows

are used with a Welder’s Gap of 3/32” (the

default is 1/8”).

Note:

All Take-Out calculations are based

on Carbon Steel O.D. See the

Cut Length

– Known Take-Out Value

example to solve

Cut Lengths for known Take-Out values.

KEYSTROKE

DISPLAY

ALL CLEArEd

(cont'd)

(cont'd)

KEYSTROKE

DISPLAY

KEYSTROKE

DISPLAY