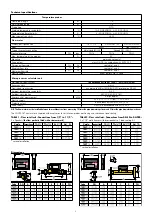

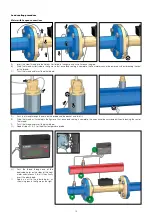

Test Instructions

The 7507 series meter is equipped with a fast output test

device located inside the plastic container.

In order to access this, remove the seal and take out the

fixing screws.

On the right-hand side of the back of the card (fig. 1) there is

a key offering access to the technical manual.

An input pulse can be simulated by connecting pins 11 - 12 (fig. 3).

The maximum input pulse frequency is 1 Hz.

After pressing the key on the back of the card, pressing

the key on the front allows you to scroll through the various

screens.

The energy increases according to the following equation:

D

E

=

κ⋅

D

T

⋅

D

V

⋅

0,2777698

⋅

10

-3

[Wh]

The probes, which absolutely cannot be separated from the electronics circuit,

may be inserted in a thermostatic bath, observing the temperature range of

10–90 °C and taking account of a

D

T between 3–80 K

(fig. 1)

(fig. 2)

(fig. 3)

ELECTRONICS BOX REAR PART

CABLE ROUTE

TEAR-PROOF CABLE CLIP

A

A

A

A

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

24 V (ac)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

RS48

5

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

Cooling unit

s

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

digital inpu

t

A

B

Heating units

4

th

pulse inpu

t

3

rd

pulse inpu

t

pulse input

blue wire

white wire

Wh

8

κ

= thermal coefficient [kJ/m

3

K]

D

T

= temperature change [K]

D

V

= volume change [ l ]

D

V = N

⋅

P

where N = number of pulses

P = single pulse value per litre

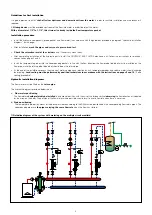

Operating specifications

1) In order to protect against spurious measurements or undesired metering, the metering control software makes the processing of consumption

subordinate to a specific flow temperature value (FT).

The

heating metering cycle is activated for FT > 22 °C

(factory setting).

The

cooling units cycle is activated for FT < 15 °C

(factory setting, with optional accessory code 755810).

On request, the setpoint values can be changed by technical personnel.

2) The software governing metering moreover has consumption processing subordinate to

a

minimum temperature difference

in order to provide further protection against spurious measurements or minimum metering due to

temperature tolerances. At the time of factory setting,

a dead band of 0,4 K

(factory setting) is therefore defined.

3) The software governing metering also requires

installation of the flow rate meter on the return pipe

.

On request and further to the action of technical personnel, the configuration setpoint can be adapted in order to install the meter on the flow

pipe.