18

19

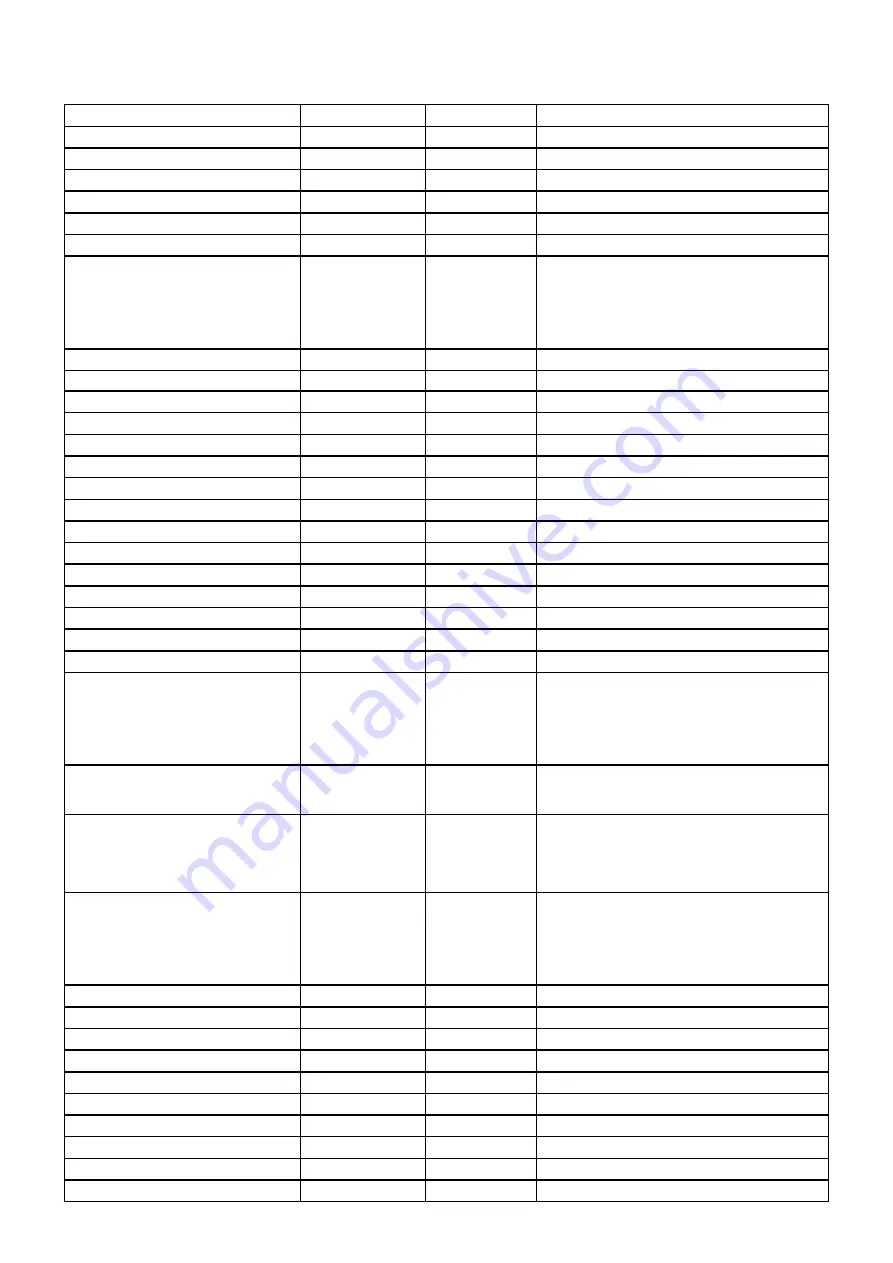

Appendix 7. LEGIOMIX_2.0_6000_SERIES MODBUS RTU MAPPINGS TO BACNET

Point Name

BACnet Object Type BACnet Object ID

Description

Model

AI

1

6002

ID Modbus

AI

2

1...250

T1

AI

3

°C/10 - °F/10

T2

AI

4

°C/10 - °F/10

ID Number

AI

5

1701...9952

Serial Number

AI

6

0001...9999

Status

AI

7

0 = Motor test

1 = Zero acquisition

2 = Full scale acquisition

3 = Water mixing status

4 = Thermal shock status

5 = Thermal disinfection status

Alarms AL01

BI

8

1 = AL01

Alarms AL03

BI

9

1 = AL03

Alarms AL04

BI

10

1 = AL04

Alarms AL05

BI

11

1 = AL05

Alarms AL06

BI

12

1 = AL06

Alarms AL07

BI

13

1 = AL07

Alarms AL08

BI

14

1 = AL08

Alarms AL09

BI

15

1 = AL09

Alarms AL10

BI

16

1 = AL10

Alarms AL11

BI

17

1 = AL11

IN1 Status

BI

18

1 = disabled ; 0 = enabled

IN2 Status

BI

19

1 = disabled ; 0 = enabled

OUT1 Status

BI

20

1 = enabled ; 0 = disabled

OUT2 Status

BI

21

1 = enabled ; 0 = disabled

OUT3 Status

BI

22

1 = enabled ; 0 = disabled

Adjustment Status

AI

23

0 = Not in progress

1 = On max temperature limit

2 = T1 enabled control

3 = T2 enabled control with d2 type

4 = T2 enabled control with d1 type

5 =

D

T measurement in progress

Motor Status

AI

24

0 = Motor stopped

1 = Motor opening

2 = Motor closing

Device Adjustment Status

AI

25

0 = Without adjustment

1 = Adjustment on band 1

2 = Adjustment on band 2

3 = Adjustment on band 3

4 = Adjustment in position

DN

AI

26

0 = DN15

1 = DN20

2 = DN25

3 = DN32

4 = DN40

5 = DN50

Seconds

AI

27

0...59

Current Day

AI

28

1...7

Firmware

AI

29

Firmware

Software

AI

30

Software

Checksum

AI

31

Checksum

Encoder Position

AI

32

Encoder Position

Day

AV

33

1...31

Month

AV

34

1...12

Year

AV

35

0...99

Hour

AV

36

0...23