7

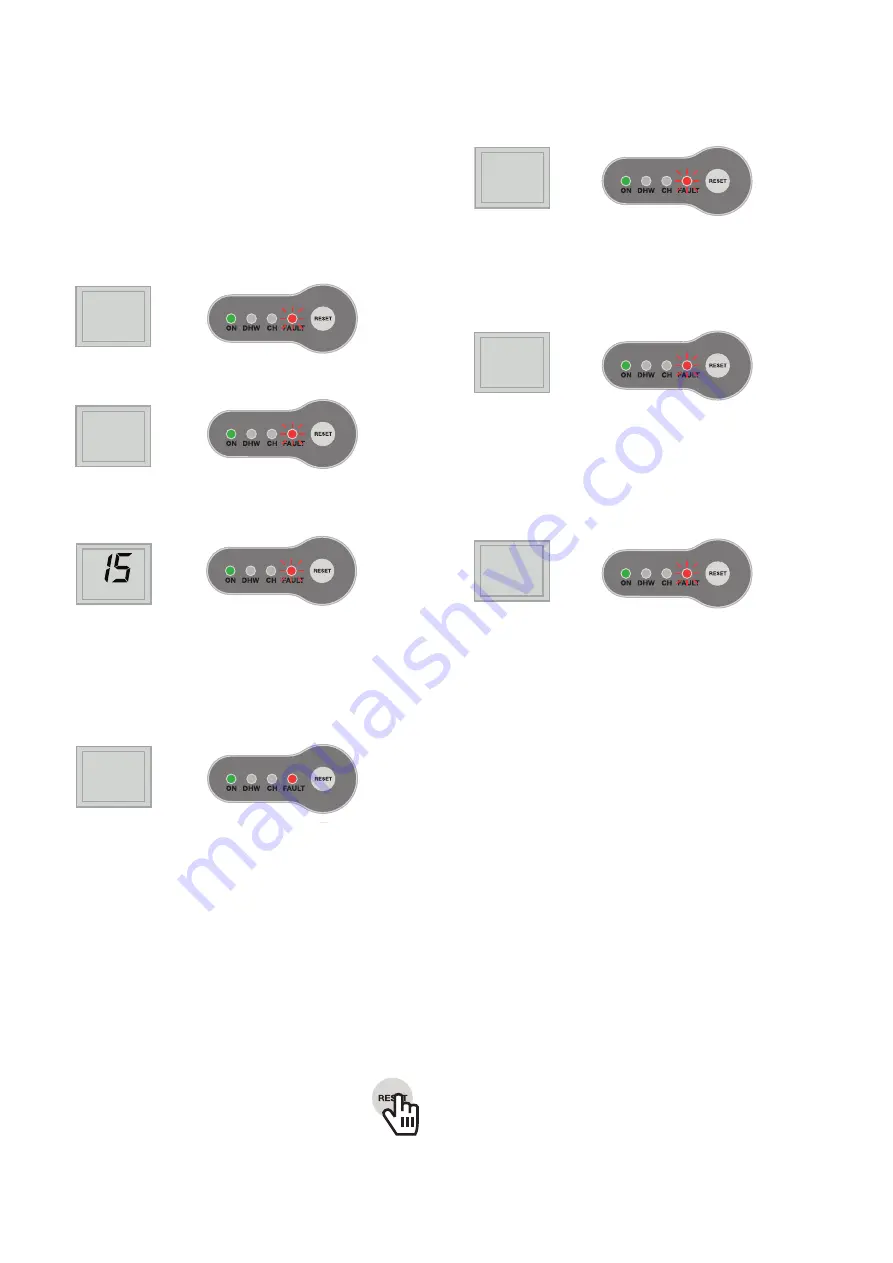

Safety thermostat cut-out

SATK20103HE - LOW temperature

Error code 69

The HIUs configured to support low temperature heating

continuously monitor the safety thermostat controlling the flow

temperature.

If the safety thermostat is activated during a general cycle, the

heating circulation pump immediately comes to a stop and the

modulating/mixing valve is completely closed. The thermal safety

lock valve (SATK20103HE) is closed.

In the event of a power failure, the thermal safety valve prevents hot

water from entering the heating system.

After the user has reset the block imposed by the safety thermostat,

the shut-off valve can only be re-enabled when the

mixing/modulating valves are completely closed again.

This means that if a domestic water cycle is in progress, the

activation of the shut-off valve will be postponed until the end of that

domestic water cycle.

Removing a fault

To restore the operating mode press the manual

RESET button.

Safety and alarms

Error codes associated with faults signalled by illumination of the

FAULT LED are also shown on the display.

69

Removing a fault

Normal operating conditions are restored automatically once the

faulty safety valve is working properly again.

Thermal safety valve fault

SATK20103HE - LOW temperature

Error code 76

76

Removing a fault

Normal operating conditions are restored automatically once the

faulty probe is working properly again (see page 12).

Probe fault

If a temperature probe fails, the associated cycle will be stopped

immediately and disabled.

Any requests to run cycles not associated to the previous one will

continue to run normally.

Heating probe fault

Error code: 5

5

Domestic hot water probe fault

Error code: 6

6

Compensation probe fault

SATK20103HE - SATK20203HE

Error code: 15

Automatic controller functions

Reset mixing/modulating valve to zero

Immediately after the power supply has been switched on, the

position of the installed mixing/modulating valves is reset to zero.

Pump anti-clog

When the pump is not in use, it is powered on for a period of

5 seconds every 24 hours.

Mixing valve/modulating valve anti-clog

The anti-clogging cycle for the mixing/modulating valve is run every

24 hours.

Removing a fault

Restore correct switch setting according to table 1

(page 6).

Incorrect switch setting

Error code 79

79

Removing a fault

The heat interface unit is disabled due to incorrect setting of the

dip-switches. Restore correct setting according to table 1

(page 6).

Incorrect dip-switch configuration (heat interface unit disabled)

Error code 80

80