14

preriscaldo

ricircolo

Impostazione default limitazione

portata massima

Esempio limitazione portata massima

Impostazione relè di default

Impostazione default limitazione

portata massima

Ciclo antilegionella

Primary flow rate limitation

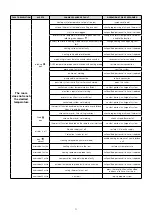

(*) The correspondence between valve position and flow rate is indicative. Graphs obtained with pressure head upstream of the HIU = 50 kPa.

N.B. Any limitation must be assessed in accordance with the effective thermal characteristics of the residential unit served.

Anti-legionella function

preriscaldo

ricircolo

Impostazione default limitazione

portata massima

Esempio limitazione portata massima

Impostazione relè di default

Impostazione default limitazione

portata massima

Ciclo antilegionella

Primary flow rate limitation in heating mode

DEFAULT SETTING: no limitation

(technical parameter t03 = 100) (SATK2230./SATK2240. only)

During start-up of the heating cycle from cold, e.g. on changeover

from night-time ambient set point to the daytime set point, the HIU

may demand a significantly higher primary flow rate than the design

one, because of the low temperatures of the secondary medium. This

effect is far greater with high temperature systems in which, during the

transient to the design operating condition, high thermal power values

may be transferred from the primary circuit to the secondary circuit.

This effect can be restricted by lengthening the transient, setting a limit

on the maximum primary flow rate that can be withdrawn in heating

mode.

The flow rate limitation is imposed by controlling the maximum

opening of the primary circuit modulating valve. The corrispondence

between degree of opening (%) and Kv of the circuit that connects the

primary flow to the secondary flow is shown in the following graph:

Primary flow rate limitation in DHW mode

DEFAULT SETTING: no limitation

(technical parameter t04 = 100)

Likewise, you can establish a limit to the primary flow rate that can be

tapped for instantaneous DHW production.

The flow rate limitation is imposed by controlling the maximum

opening of the primary circuit modulating valve. Since latter is

controlled by a differential pressure limiter, it is possible to supply

direct correspondence between the opening position of the valve and

the circulating flow rate (*)

A maximum degree of opening (%) can be set via technical menu

parameter t03.

A maximum degree of opening (%) can be set via technical menu

parameter t04.

Max opening (%)

kv (m

3

/h)

70

60

50

80

100

90

0

0,25

0,50

0,75

1,00

1,25

1,5

Max opening (%)

Flow rate (l/h)

70

60

50

80

100

90

0

200

400

600

800

1000

1200

1,75

2,0

Max opening (%)

kv (m

3

/h)

70

60

50

80

100

90

0

0,25

0,50

0,75

1,00

1,25

1,5

Max opening (%)

Flow rate (l/h)

70

60

50

80

100

90

0

200

400

600

800

1000

1200

1,75

2,0

DEFAULT SETTING: anti-legionella function OFF

(technical parameter t08 = 0)

Enabling the anti-legionella function by means of technical parameter

t08 = 1, in time band 3:00 - 3:30:

- the DHW set point will be temporarily increased to the maximum

value (60°C) - the comfort/recirculation function will be forced ON.

As a result of the temperature rise of the set point, at time 3:00 a

comfort function (either pre-heating or recirculation) will be triggered,

bringing the temperature to a value close to 60°C, such as to rapidly

reduce the presence of any bacteria.

During execution of the cycle, the user interface display will show the

blinking ( ) symbol (refer to the adjacent figure).

IMPORTANT!

- Any DHW production that occurs during the time band (3:00

- 3:30) will be at 60°C.

- The cycle execution time band (3:00 - 3:30) is established

in accordance with the time set on the remote control unit.

Incorrect time setting will result in execution of the anti-

legionella function in a different actual time band.

Due to the effect of exchanger thermal inertia, temporary DHW

production at high temperature could proceed also beyond the

time of 3:30.

If the function is enabled thermostatic mixing valves should be

installed on the users level (washbasin/shower, etc.).

antilegionella

(mode)

ACS ON/OFF

Risc. ON/OFF

(set)

Ora/giorno corrente

Temperature di set point

k regolazione climatica

(day/night)

Set diurno/notturno

(temp)

Visualizzazione

temperature

(set point am

sonde)

(prog)

Programmazione oraria

riscaldamento e funzione

“comfort”

(reset)

Reset errore riarmabile/funzione

scaldamassetto

(R)

+/-