24

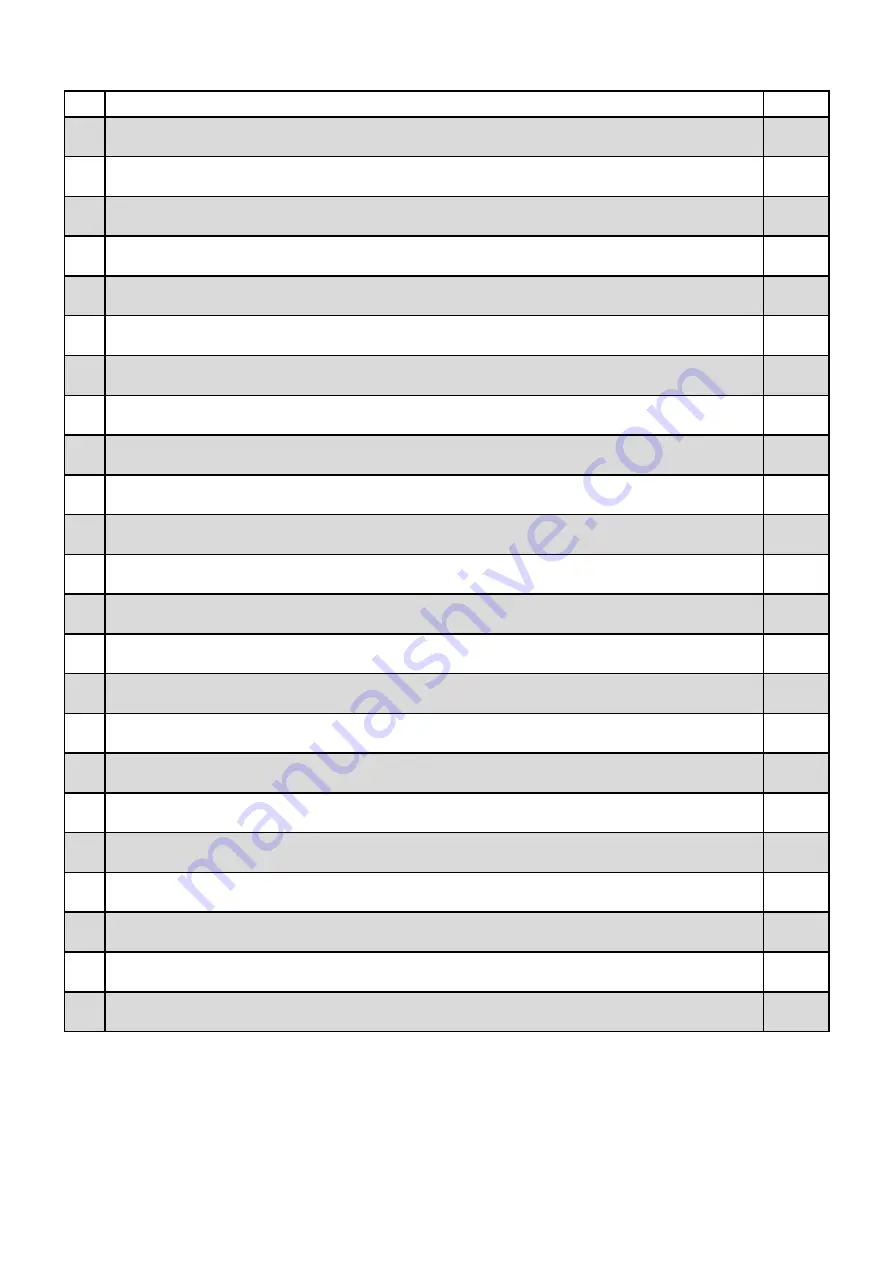

Commissioning check-list

Checks to be performed

1

Is the heat interface unit properly secured to the wall?

2

Has the system flushing been carried out?

3

Check strainers and clean them if necessary

4

Is the heat meter (if present) connected?

5

Is the heat meter (if present) connected to the building datalogger (if required)?

6

Is the DCW line fitted with a pressure reducing valve?

7

Are the shut-off valves open?

8

Has the visual inspection of the hydraulic sealing efficiency produced positive results?

9

Has the system (primary) been filled and vented?

10

Has the visual inspection of the HIU internal electrical connections given a positive result and are the

connections compliant with specifications and made in accordance with best practices?

11 Is the heat interface unit connected to the 230 Vac electric supply? Is the remote user interface connected?

12

Have the optional connections (external sensor, prepayment, auxilliary microswitch, Modbus, if required)

been carried out?

13

Has the remote user interface been configured for installation on board (thermostat function disabled) / inside

the apartment (with thermostat function enabled)?

14 Have the heating, DHW and comfort functions (if required) been activated?

15 Have the heating and DHW set points been configured correctly?

16

Have the optional functions (return temperature limitation, return/weather compensation, anti-legionella, primary

flow rate limitation) been enabled (if required) and configured?

17 Have the external room thermostats (if required) been connected?

18 No error code on heat interface unit remote user interface?

19 Is the primary circuit at working temperature?

20 Check that heating starts (blinking icon) by simulating a heating request

21

Check that the pump functions correctly when the thermostat is activated (check that the secondary flow pipes

heat up)

22

Simulate minimal DHW tapping (approx 3 l/min) and check that “DHW” LED lights and that water is supplied at

the required temperature

23

Simulate abundant DHW tapping and check, by means of the installed heat meter, that the primary circuit flow

rate is sufficiently high