8

1

2

3

4

5

6

7

Electrical installation

Connection to the electric supply

The appliance is supplied with an electric supply cable which is not

fitted with a plug.

The appliance should be electrically connected to a 230 V (ac) single-

phase + earth mains supply using the three-wire cable marked with

the label as specified aside, observing the LIVE (L) - NEUTRAL (N)

polarities and the earth connection. This line must be connected to a

circuit breaker device.

To extend the cable if necessary, use a flexible cable suitable for

kitchen and heating appliances and for home, kitchen and office

installations, also in humid environments subject to medium levels

of mechanical stress (e.g. H05V2V2-F: Uo/U 300/500 V). Cable

minimum cross-section 3 x 0,75 mm

2

.

Make sure that the electrical system can withstand the maximum

power consumption of the appliance, with particular emphasis on the

cross-section of the wires.

If you have any doubts, contact a qualified technician to request a

thorough check of the electrical system.

Electrical safety of the appliance is only achieved when it is correctly

connected to an effective earthing system, constructed as specified

in current safety regulations. This is a compulsory safety requirement.

Observe the applicable regulations in force in the country of installation.

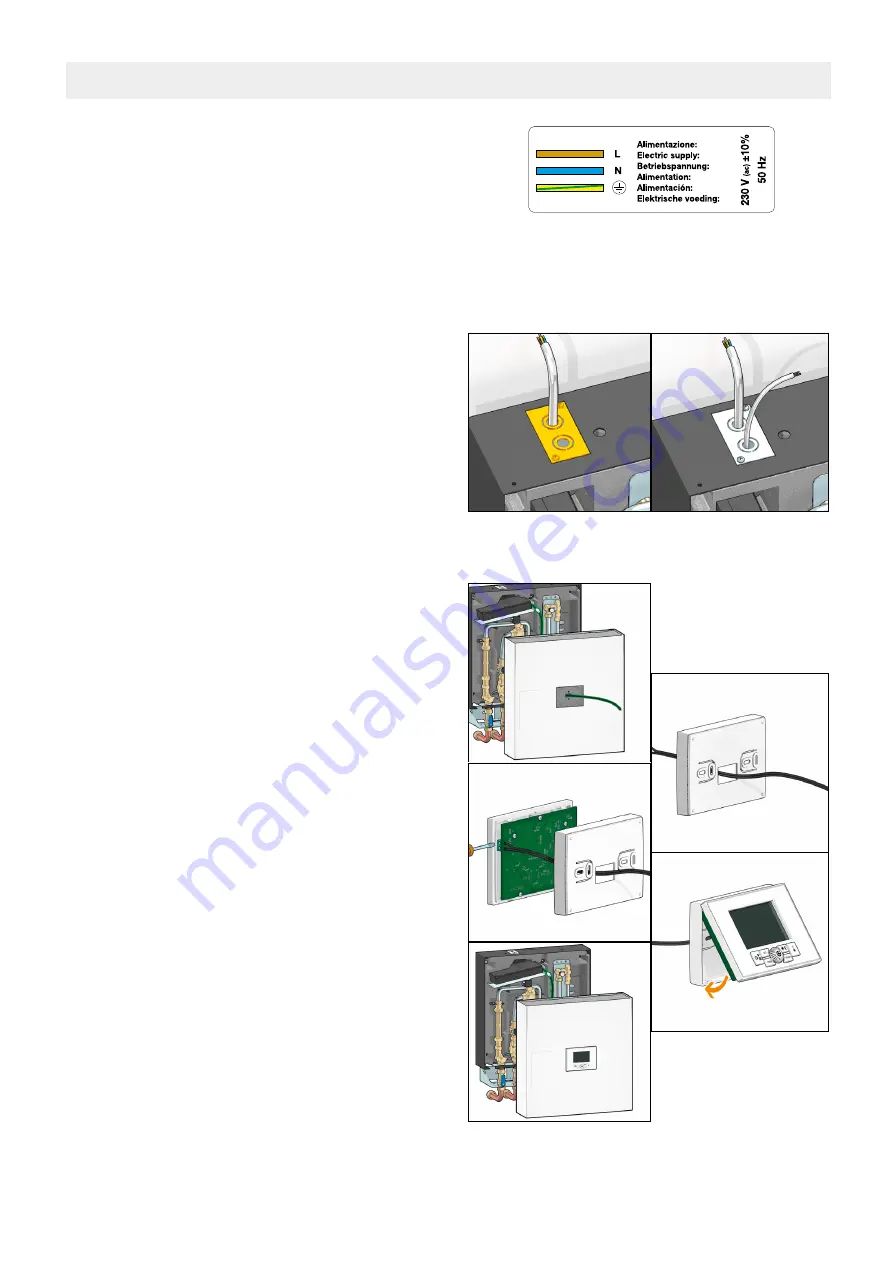

Use the cable pathway provided, as shown in figure 1.

Optional electric connections

The controller has a door on the front providing access to terminal

boards for optional wiring (see chapter “circuit board details”). The

connections in question are all low voltage or potential-free. Any wiring

must be directed toward the exterior of the HIU, using the pathways

provided in the insulation and on the frame. All the low voltage lines

must be routed through a single dedicated cable raceway, using the

pathway that is not used for the electric supply cable (see figure 2), so

that they are separate from the 230 V electric cables.

Any other high voltage connection, e.g. the one from the auxilliary

microswitch (see pages 13 and 16) must pass through the same cable

pathway used for the main electric supply.

Remote user interface connection

The HIU user interface has the dual function of control device and

room thermostat. The remote user interface can be installed on

board the HIU or in the room in a position where the temperature

measurements will be of significance for control of the heating function

(in a heated room in a position where the temperature read by the

thermostat is not affected by any nearby heat sources).

Installation on board the HIU

If the remote user interface is fitted in the dedicated location on the

cover of the HIU, the thermostat function must be disabled (in this

case an external thermostat must be used, as described in the next

section). The adjacent figures show how to install the remote control

unit:

- Feed the cable from the regulator through the hole in the cover (3);

- Feed the cable from the regulator through the rear of the interface

(4);

- Connect the two wires to the terminals on the electronic circuit board

(the cable is not polarised) (5);

- Close the interface and position it in its housing on the cover (6), (7);

- If necessary, secure the interface from inside the cover by means

of the supplied pair of self tapping screws, spacers, and washers;

- Plug in the connector.

The thermostat function is enabled by default (refer to the

remote control user manual for disabling it).