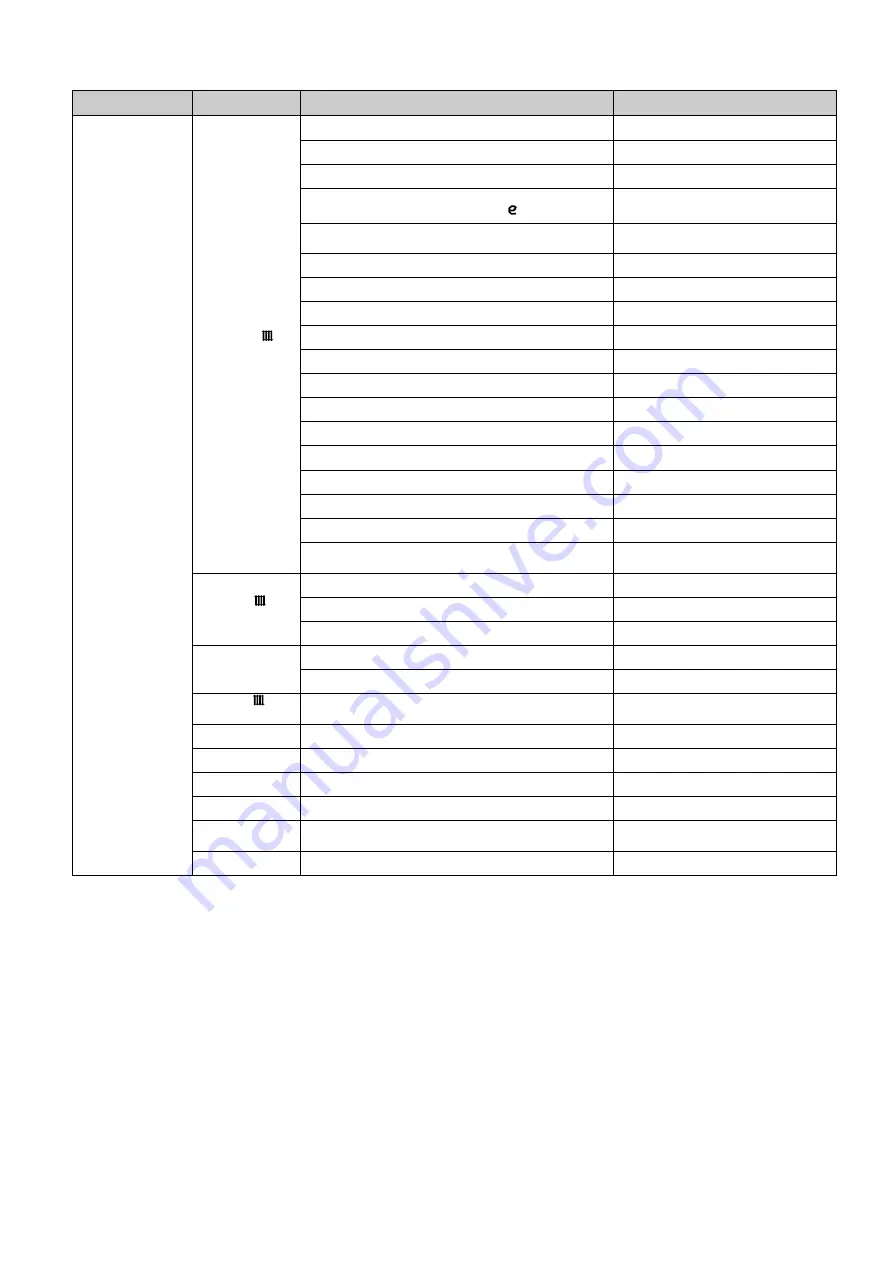

23

FAULT DESCRIPTION

ALERTS

POSSIBLE CAUSE OF FAULT

OPERATIONS TO BE PERFORMED

The room

does not reach

the desired

temperature

blinking

icon

heating cycle temperature set point too low

increase set point

chrono-thermostat temperature setting incorrect

check programming of chrono-thermostat

HIU strainer clogged

call qualified personnel to have it serviced

primary return temperature limitation intervention (the

following icon appears

)

change the return temperature set

point/disable the function

primary flow rate in heating mode set at an excessively

low limit

change heating valve opening limit

heating valve actuator faulty

call qualified personnel to have it replaced

heating valve obturator blocked

call qualified personnel to have it replaced

modulating valve actuator connector disconnected

reconnect actuator connector

DHW temperature probe cable inverted with heating probe

restore correct connection

presence of air in the system

vent the system

pump not working

call qualified personnel to have it replaced

pump cable not connected

restore connection

possible system shut-off valves/terminals closed

open the valves

centralised system temperature insufficient

contact person in charge of system

electronic regulator not working

call qualified personnel to have it replaced

primary circuit flow rate insufficient

contact person in charge of system

centralised system not working

contact person in charge of system

thermostat function enabled on the remote user interface

when it should be disabled

contact person in charge of system

fixed

icon

chrono-thermostat time setting incorrect

check programming of chrono-thermostat

chrono-thermostat not working

check chrono-thermostat

thermostat function disabled on the remote user interface

contact person in charge of system

display is off

Electric supply cut off

restore HIU electric supply

Protection fuse burnt out

call qualified personnel to have it replaced

icon

absent

Heating not enabled (summer mode)

enable heating by means of heat interface

unit

error code 4 active

heating circuit pressure too low

restore system pressure

error code 5 active

heating temperature probe faulty

call qualified personnel to have it replaced

error code 15 active

compensation temperature probe faulty

call qualified personnel to have it replaced

error code 38 active

external temperature probe faulty/not connected

call qualified personnel to have it replaced

error code 69 active

safety thermostat cut-out

press the reset button/call qualified

personnel to have it serviced

error code 80 active

no credit

top-up prepaid system