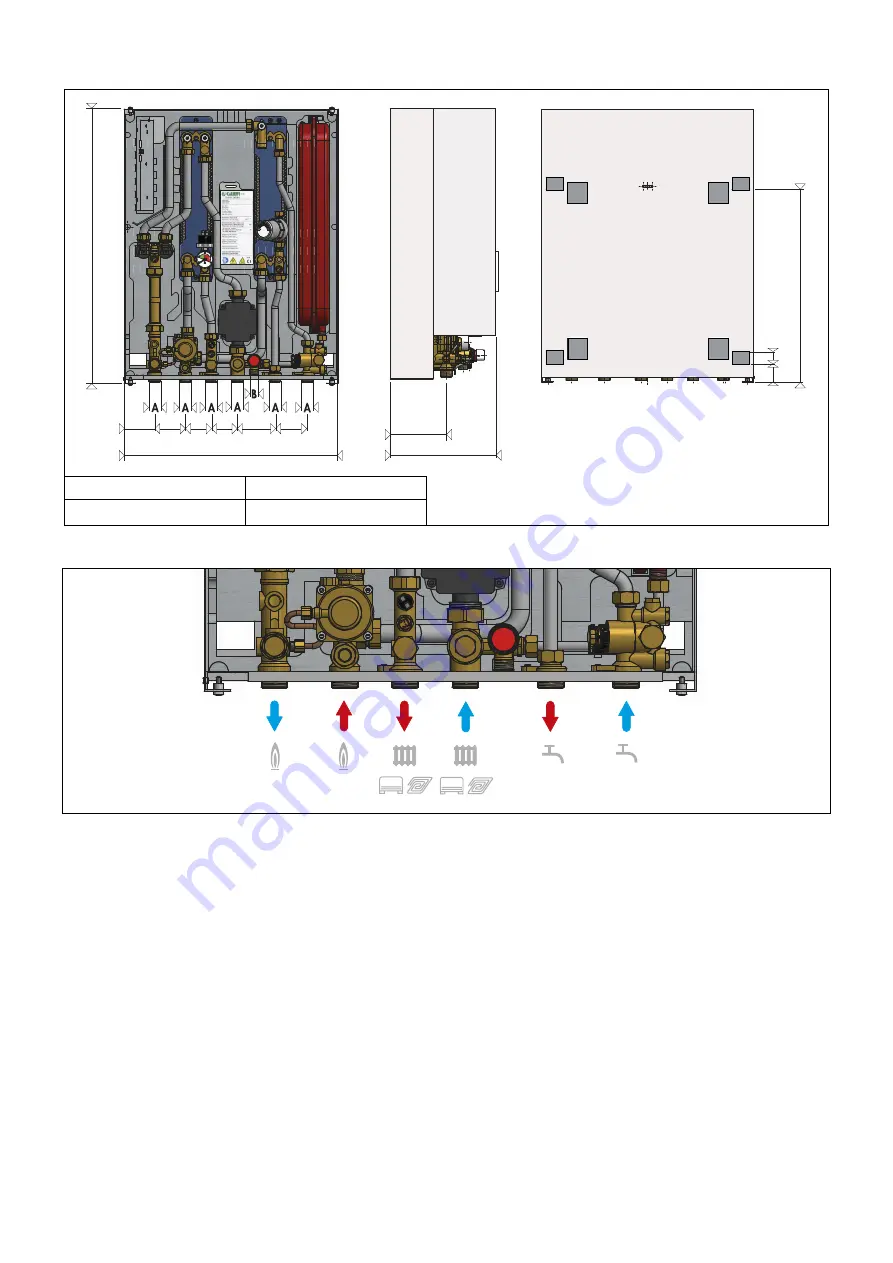

3

130

245

70

70

60

60

85

75

490

6

3

0

4

2

2

8

4

4

4

Dimensions

SATK32 technical specifications

Medium: water

Max. percentage of glycol: 30%

Maximum medium temperature: 90°C

Max. working pressure: - primary circuit: 1,6 MPa (16 bar)

- secondary circuit: 0,3 MPa (3 bar)

- domestic circuit: 1 MPa (10 bar)

Primary circuit nominal flow rate: 1,2 m

3

/h

Nominal pressure loss on primary circuit:

D

p 50 kPa (0,5 bar)

Maximum pressure on primary circuit:

D

p 600 kPa (6 bar)

Domestic water circuit max. flow rate: 24 l/min (0,4 l/s)

Minimum flow rate to activate domestic water flow meter: 2 l/min ±0,3

Electric supply: 230 V (ac) ±10% 50Hz

Max power consumption: 80 W

Protection class: IP 40

Pump: UPM3 15-70

Actuators: 24 V stepper motor

Probes: NTC 10 k

Ω

Safety relief valve setting: 0,3 MPa (3 bar)

Safety thermostat: 55°C ±3

Expansion vessel:

- capacity: 7 l

- pre-charge value: 0,1 MPa (1 bar)

Pressure switch: - opening: 40 kPa (0,4 bar)

- closing: 80 kPa (0,8 bar)

Materials

Components: brass UNI EN12165 CW617N

Connecting pipes: steel

Frame: RAL 9010 painted steel

Exchanger: stainless steel brazed with copper

Insulation

Material: EPP

Density: 45 kg/m

3

Working temperature range: 3-90°C

Thermal conductivity: 0,04 W/mK

Description of connections

A

B

3/4”

1/2”