16

Auxiliary microswitch

Event/condition

Value

DHW tapping in progress

1

Heating cycle in progress

2

Comfort cycle (pre-heating/recirculation) in progress

4

HIU OFF

8

Error not active

16

Error active

32

The HIU is equipped with a contact, driven by a relay incorporated in

the circuit board, the intervention logic of which can be programmed

in accordance with requirements by setting technical parameter t05.

Each event linked to operation of the HIU is linked to a numerical

value, according to the following table:

Closing of the contact on the occurrence of multiple events conditions

is programmed by setting parameter t05 to a value corresponding to

the sum of the single events/conditions.

We give some practical examples below:

example 1 - Driving an external primary flow pump, normally OFF.

The contact must be closed if any HIU function is active (DHW

production, heating, pre-heating)

Parameter t05 must be set to: 1 + 2 + 4 = 7

This value (t05 = 7) is

set by default

.

example 2 - Distinction of consumption for DHW production from

total consumption (in combination with heat meter equipped with

dedicated function)

The contact must be closed both if DHW tapping is in progress and if

activation of the comfort function is requested (pre-heating or

recirculation).

Parameter t05 must be set to 1 + 4 = 5.

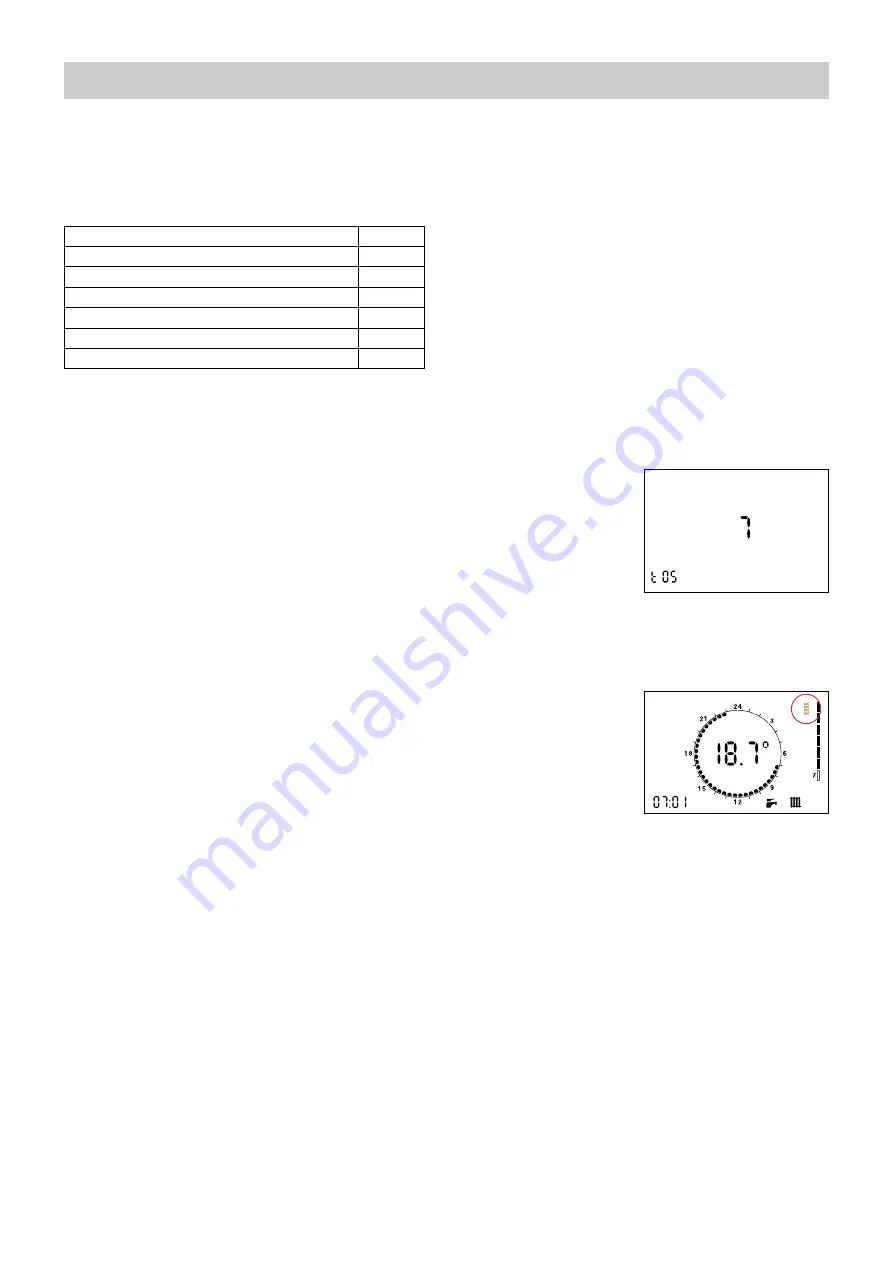

Closing of the microswitch is shown on the user interface by the

symbols shown alongside.

N.B. if the DHW recirculation function is enabled with t02 = 1

(see page 13) the auxiliary microswitch intervention logic

described above is not operational. In this case, the contact is

used to control the recirculation pump.

N.B.: the auxiliary microswitch can be used to drive electric

loads directly, taking account of the following operating limits:

- Max voltage: 230 Vac

- Max current: 3 A

If the electric load to be controlled is not included within the

parameters indicated an external relay must be interposed.

Connection

For information on how to access the dedicated terminals, consult the

“auxiliary microswitch” section on page 19.