• Mod-Bus

RS-485 port to connect HIU to a wired network for

Mod-Bus communication.

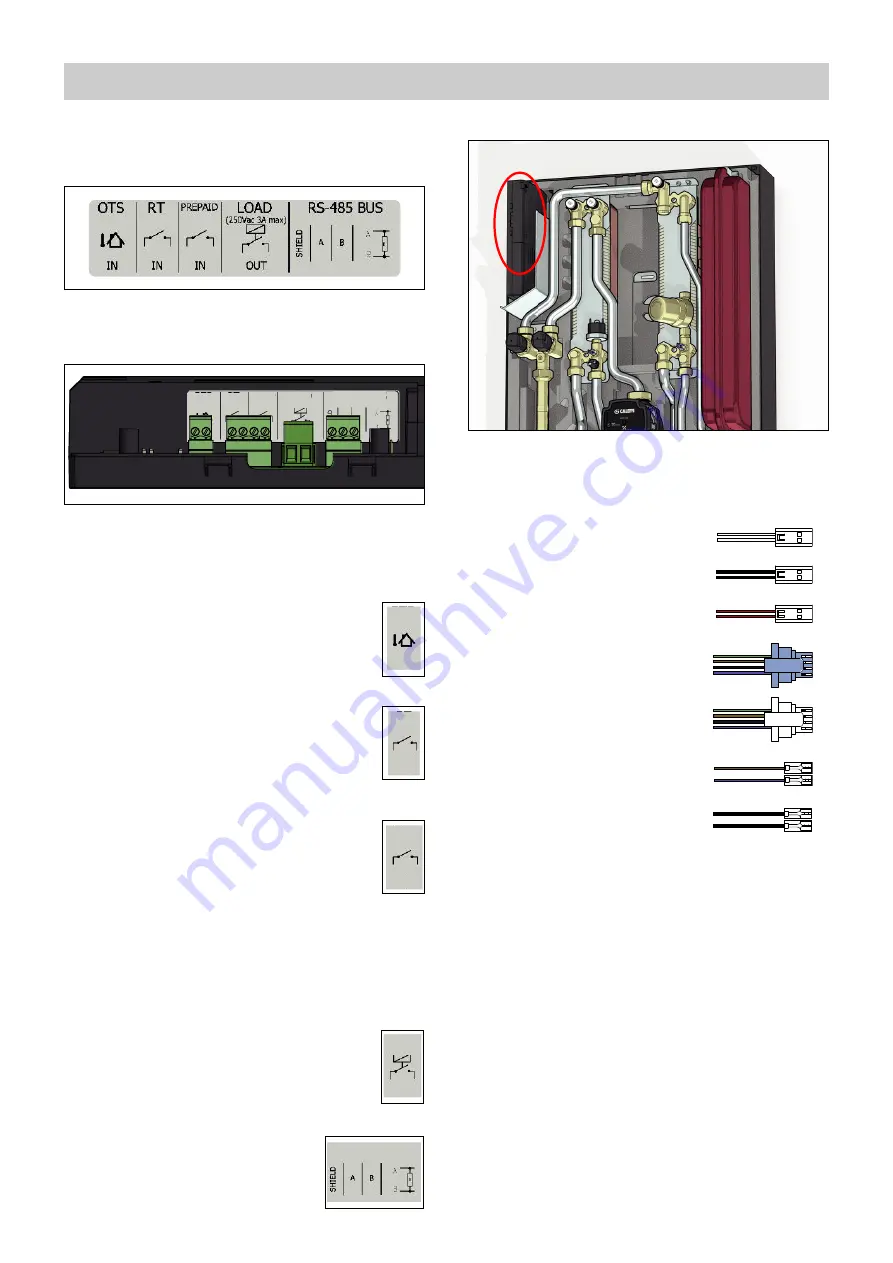

Electronic circuit board

Other electronic regulator functions

• Reset diverter/modulating valve to zero

Immediately after the power supply has been switched on, the

position of the modulating valves is reset to zero.

• Pump anti-seizing

When the pump is not in use, it is powered on for a period of 5

seconds every 24 hours.

• Diverter/modulating valve anti-seizing cycle

The anti-seizing cycle for the diverter/modulating valve is run every 24

hours.

• Auxiliary contact

To implement the functions described on page 16 and for the

connection of the DHW recirculation pump (see page

13)

IMPORTANT! Max voltage 230 V ac, max current 3 A.

Optional connections

The electronic circuit board has a front door (shown in the adjacent

figure) that provides access to the connectors related to HIU optional

functions.

N.B. before working on the circuit board you must disconnect

the electric supply to the HIU.

The following services are accessible:

• External probe for outside compensated temperature

regulation

Use optional probe code 789833

• External room thermostat

IMPORTANT! The connection is volt free.

Do not connect powered contacts.

• Interface with pre-paid services

In case the HIU has to be interfaced with controllers

managing the heating and DHW production services by

means of “pre-paid” type logic.

The HIU interprets an open contact as “credit available”.

Closing the contact disables the heating and DHW

production services. When this condition occurs the user interface

display shows error “E80”.

IMPORTANT! The connection is volt free.

Do not connect powered contacts.

If the controller that manages the pre-paid service supplies a powered

contact, a relay must be interposed.

All the terminals are mounted on removable connectors to facilitate

wiring operations.

Connector colours

If the connectors of actuators and temperature probes are

disconnected during special maintenance work, comply with the

following instructions to reconnect them:

DHW probe:

Return probe:

Heating probe:

Heating valve actuator connector:

DHW valve actuator connector:

19

OTS

RT

PREPAID

AUX

RS-485 BUS

250Vac 3A

max

RS-485 BUS

?

OTS

RT

P

IN

IN

IN

OUT

I

RT

P

IN

IN

OUT

I

PREPAID

IN

OUT

I

AUX

R

????????

OUT

I

3

5

2

an die Art.Nr. 789835

• Gebruik deze enkel voor aansluiting op code 789835

• Utilice solamente para la conexión con cod. 789835

• Usare solo per collegamento a cod. 789835

• Use this wire for connection to code 789835 only

• À n'utiliser que pour la liaison avec code 789835

• Verwenden Sie dieses Gerät nur zum Anschluss

an die Art.Nr. 789835

• Gebruik deze enkel voor aansluiting op code 789835

• Utilice solamente para la conexión con cod. 789835

Pressure switch:

Safety thermostat: