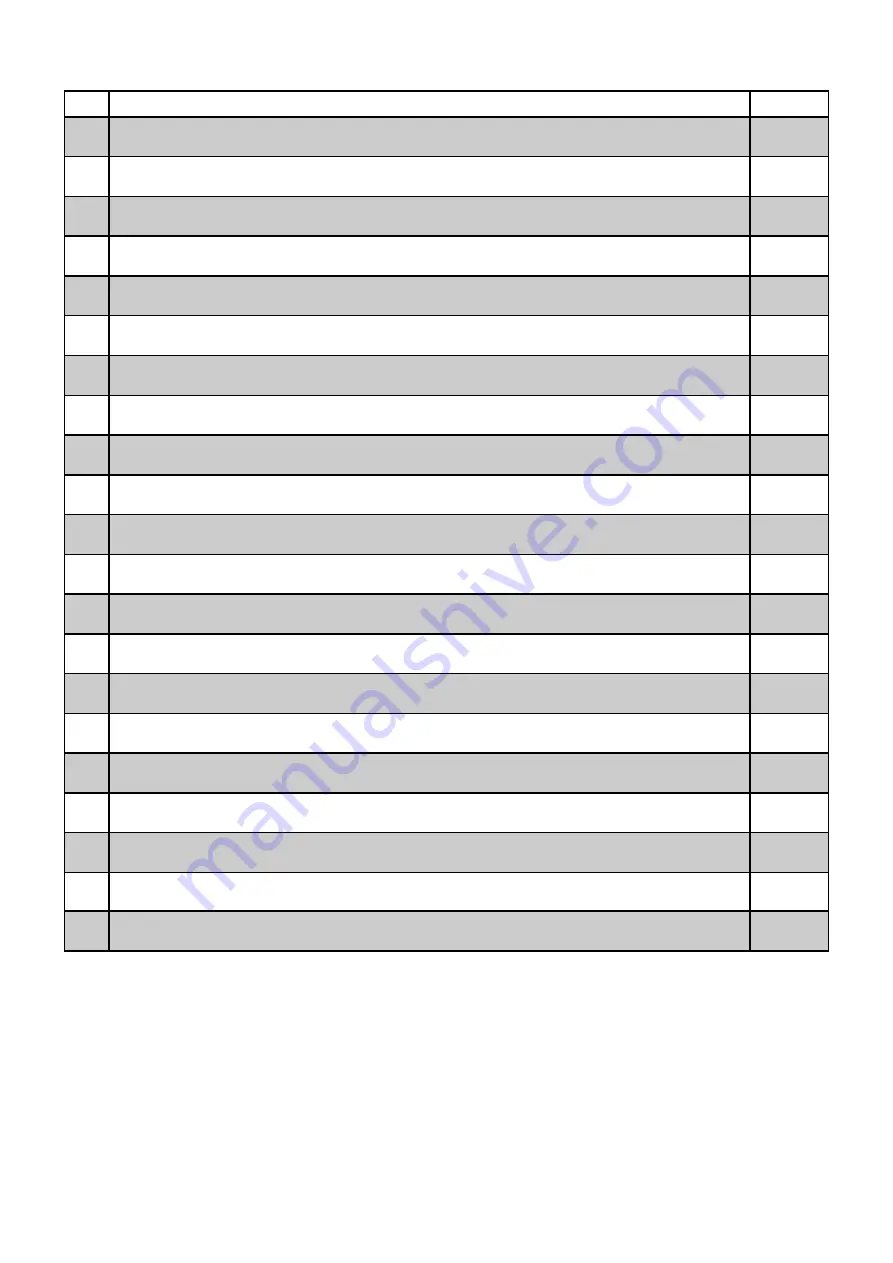

Commissioning check-list

Checks to be performed

1

Is the heat interface unit properly secured to the wall?

2

Has the system flushing been carried out?

3

Check strainers and clean them if necessary

4

Is the heat meter (if present) connected?

5

Is the heat meter (if present) connected to the building datalogger (if required)?

6

Has the modulating temperature regulation with compensated set point (normally off)

been activated (if required)?

7

Is the heat interface unit connected to the 230 V (ac) electric supply?

8

Is the room thermostat (potential-free contact) connected?

9

Has the storage thermostat been connected?

10

Has the visual inspection of the HIU internal electrical connections given a positive result and are the

connections compliant with specifications and made in accordance with best practices?

11

Are the shut-off valves open?

12

Has the visual inspection of the hydraulic connections given a positive result?

13

Has the system been filled and vented?

14

Is the heat interface unit powered (green “ON” LED lit)?

15

No alarm code (“fault” LED lit) on heat interface unit regulator?

16

Has the DHW set point temperature on the storage thermostat been set to the required value?

19

Has the heating flow temperature been set to a correct value?

18

Is the primary circuit at working temperature?

19

Check that “CH” LED lights approx. 10 seconds after the thermostat trips

20

Check that the pump operates correctly when the room thermostat trips

(check that secondary heating flow pipes start to heat up)

21

Check that the pump operates correctly when the storage thermostat trips

(check that flow pipe to the storage cylinder starts to heat up)