Manufactured in the U.S.A.

alum

LEDs

™

CALIFORNIA ACCENT LIGHTING, INC.

2820 E. Gretta Lane, Anaheim, CA 92806

ph. 800.921.CALI (2254) | fx. 714.535.7902 | info@calilighting.com | calilighting.com

© CALI. All rights reserved. CALI reserves the right to make changes or withdraw specifications without prior notice.

Page 10 of 11

INSTALLATION

ALS

600T-AD

2019.12.5 Rev 2

Troubleshooting & Continuity Test

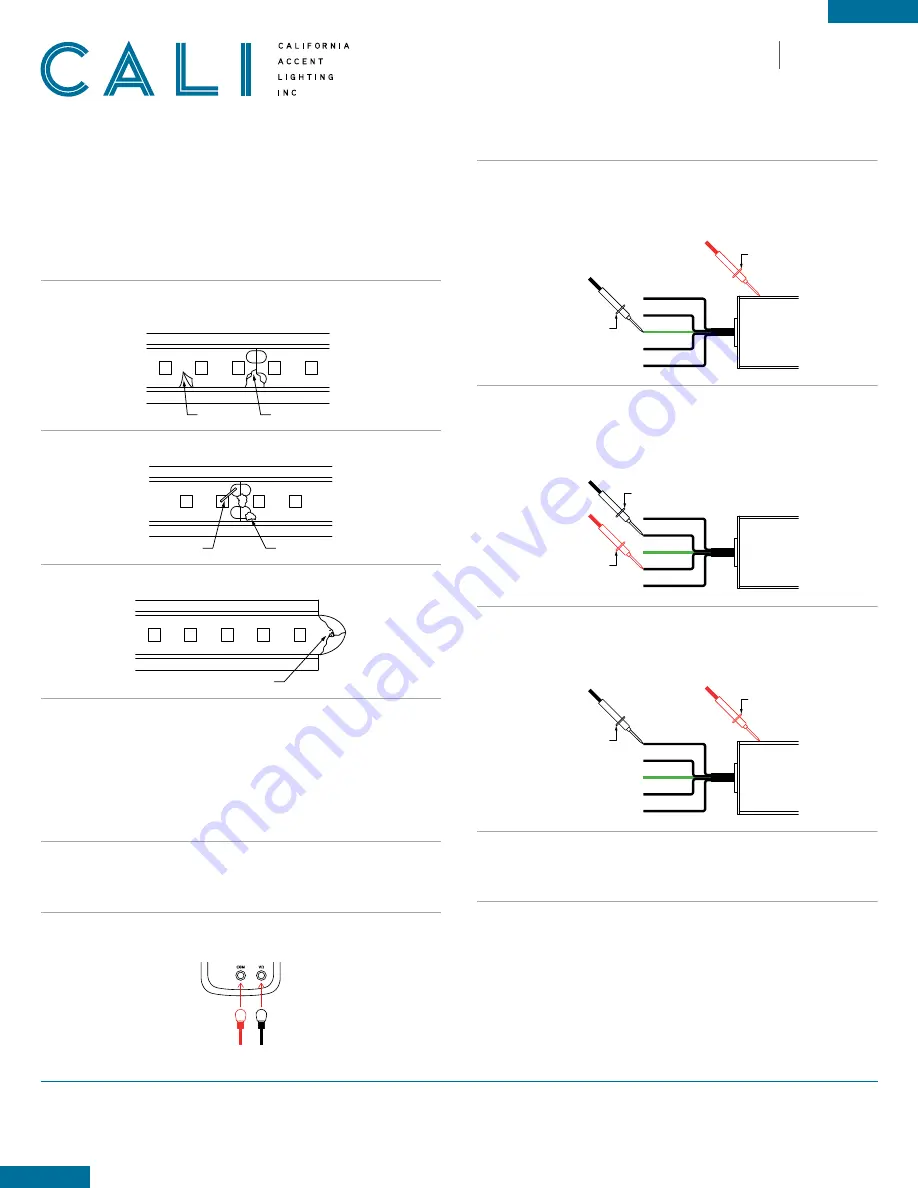

Frayed end

Copper pads touching extrusion

Foreign object

Lightstrip overlapping extrusion

Metal flakes

Damaged lightstrip

Twisted lightstrip

Torn lightstrip

Frayed end

Copper pads touching extrusion

Foreign object

Lightstrip overlapping extrusion

Metal flakes

Damaged lightstrip

Twisted lightstrip

Torn lightstrip

Frayed end

Copper pads touching extrusion

Foreign object

Lightstrip overlapping extrusion

Metal flakes

Damaged lightstrip

Twisted lightstrip

Torn lightstrip

1.

Turn off power before beginning. Check for any twisting or damage to the circuit in the LED

lightstrip. If there is excessive damage and the circuit is broken, the lightstrip must be replaced.

3.

Check to ensure lightstrip is clean and not frayed, causing copper pads to touch.

2.

Check for metal particles or other foreign objects causing the short.

TROUBLESHOOTING TIPS

• Do not reset the breaker multiple times

• If the unit is overloaded, the breaker will trip, shutting off the transformer and lights

• If the breaker reset button has been held down by hand or any type of pressure, such as duct

tape, or if the breaker has been reset multiple times without troubleshooting, the unit will:

- Burn the transformer bobbin

- Burn the thermal or magnetic breaker

- Burn the primary or secondary wires due to high amperage caused by overload

- Short circuit in line which will not allow the breaker to reset

- Damage the lighting

1.

Turn power off before beginning. Verify power is turned off by using a non-contact circuit

tester. Touch the probe of the tester to positive wire of the power source. The tester will

light up if an electrical current is detected.

3.

Verify that your tester is functional by touching probes together. The tester should light up,

beep, or read 0Ω (ohms) of resistance.

5.

Touch the red probe to a wire and the black probe to each other wire. Repeat for each wire.

If a conductive path is formed between any of the wires, the multimeter will beep, flash,

or read

0Ω

(ohms). Troubleshoot to identify the malfunction in the line. If there is no

conductive path, the multimeter will not show any feedback.

Example:

Check for continuity between Wire 2 and Wire 4

6.

Touch the red probe to the fixture extrusion and the black probe to each wire except ground.

If a conductive path is formed between the extrusion and any of the wires, the multimeter

will beep, flash, or read

0Ω

(ohms). Troubleshoot to identify the malfunction in the line.

If there is no conductive path, the multimeter will not show any feedback.

4.

Touch the red probe to the fixture extrusion and the black probe to the ground wire (green).

If the fixture is properly grounded, the multimeter will beep, flash, or read

0Ω

(ohms).

If there is no conductive path, the multimeter will not show any feedback. Troubleshoot to

identify the malfunction in the ground wire.

7.

Set voltmeter to AC voltage and test power source. Confirm the correct voltage before

connecting lighting to power source. If voltage reading is more than 1 volt higher than the

marked output voltage, there is a problem with the power source or driver.

8.

Connect power connector to power source. If LEDs do not turn on, troubleshoot to find the

problem in the line.

CONTINUITY TEST

A continuity test is performed to determine if electricity can pass through two points on

an electrical circuit. This helps identify shorts or malfunctions in the line or fixture. Use a

multimeter or continuity tester to perform the steps below.

• Always perform a continuity test before connecting lighting to power source.

• Malfunctions are not always as obvious as the lights not turning on.

• A short or malfunction in the line or fixture will cause damage over time, ultimately damaging

the lighting and voiding warranty.

2.

Setup your tester. First insert the black probe lead into the COM jack, then insert the red

probe lead into the VΩ jack.

1

2

V

AC

(-)

(+)

Black Probe

Red Probe

1

2

3

4

5

Red Probe

Black Probe

1

2

3

4

5

Red Probe

Black Probe

1

2

3

4

5

Red Probe

Black Probe

1

2

3

4

5

Red Probe

Black Probe

1

2

3

4

5

Red Probe

Black Probe

1

2

3

4

5

Red Probe

Black Probe

1

2

3

4

5

Red Probe

Black Probe

1

2

3

4

5

Red Probe

Black Probe

1

2

3

4

5

Red Probe

Black Probe