6

Customer Support: 1-866-409-4581

AIR COMPRESSOR

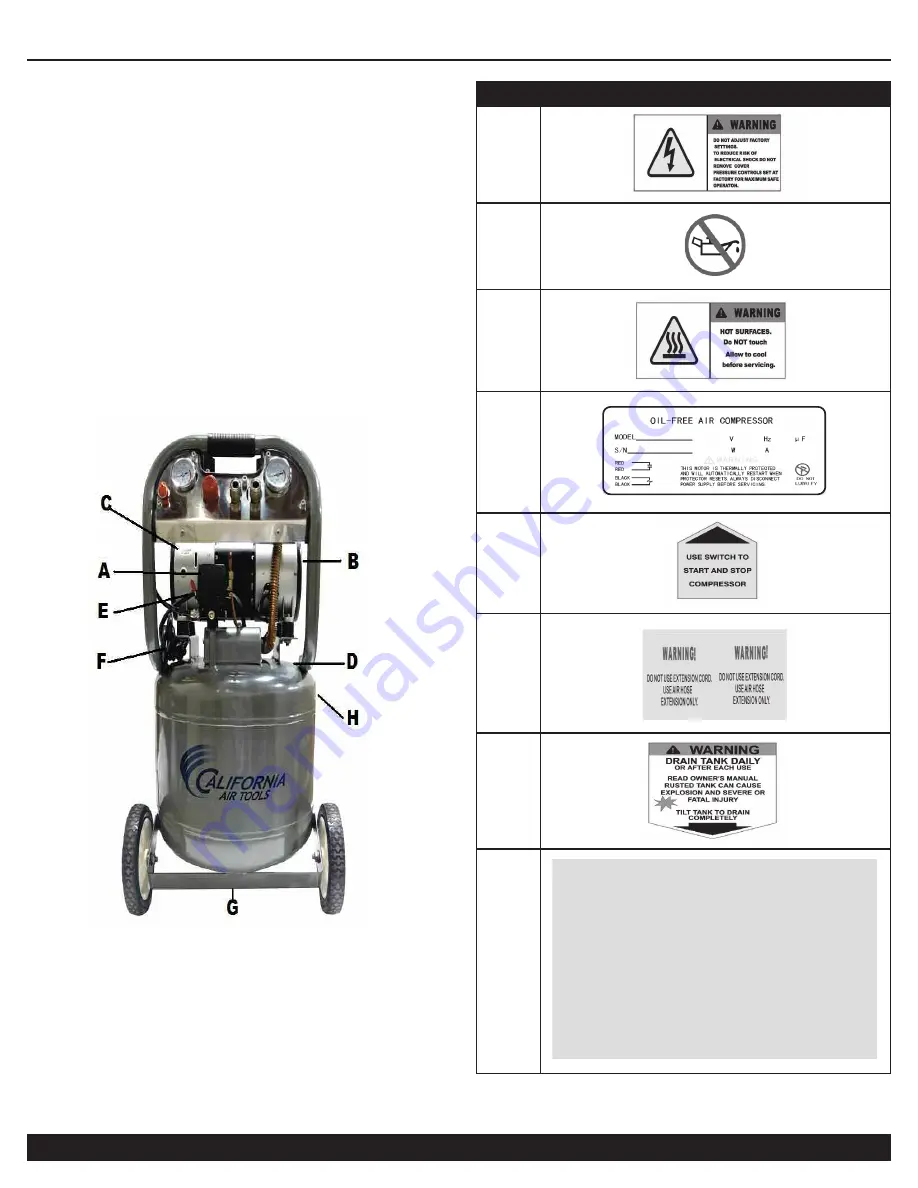

LOCATIONS OF

IMPORTANT LAbeLS

Read these important labels before operating.

These labels provide important safety and maintenance

information. These labels should be considered as permanent

parts of the air compressor. Should any of these labels become

illegible, damaged or removed, please contact California Air Tools

Customer Service department at 1-866-409-4581 for

replacements.

model: 10020-220

PROduCT LAbeL

a

b

c

d

e

f

g

h

Note:

1. The air compressor should only be placed in a well-ventilated and clean area.

2. Keep the air compressor on a firm and flat surface, with adequate space surrounding it for

ventilation.

3. If the air compressor needs repair or becomes damaged, turn off the power and drain the

tank.

4. Motors cannot be more than 10% lower or higher than the standard voltage.

5. When the compressor is running, do not touch its hot surfaces.

Routine maintenance

1. Always listen for unusual sounds, vibrations or high-pitched noises.

2. Open the drain valves to empty the air tank at least once per day.

Weekly maintenance

1. Clean the air filter weekly. Replace it with a new one after 500 hours of use.

2. Open the safety valve to ensure that it is operational.

3. Ensure that the pressure switch and check valve are operating normally.

4. Inspect all screws and connections, and tighten if any are loose.

Quarterly maintenance

1. Inspect all screws and connections, and tighten if any are loose.

2. Clean the compressor's exterior, and check for leaky connections.

3. Check the valve plate, valve, piston rings, etc., to ensure that they are operating normally.