16

Customer Support: 1-866-409-4581

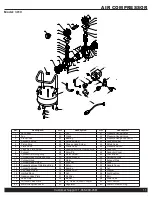

AIR COMPRESSOR

electrical power

electrical power requirements

n

before using the air compressor, refer to the serial label for

voltage and amperage requirements. Make sure you have a

sufficient electrical supply for supporting the motor's

requirements.

n

use a dedicated circuit for the best results.

n

Low voltage and/or an overload circuit can cause the motor's

overload protection system circuit breaker to trip.

electrical extension cords

n

Inspect all electrical extension cords to ensure that they are

free of damage.

n

When using an extension cord, use a heavy-duty cord that is

no more than 25 feet long and at least 14 gauge.

n

use only a 3-wire extension cord that has a 3-blade grounding

plug.

OPeRATING THe AIR

COMPReSSOR

Save this manual for future reference.

Introduction

n

This air compressor features a compact structure, stable

performance, a high airflow rate, and easy operation and

maintenance. because the air compressor produces no oil in

the airflow, it can be used as an independent air supply

machine for situations in which oil in the airflow is an issue.

n

The motor directly drives the eccentric wheel-connecting bar

system, making the piston move reciprocally. The piston is

made from a high-temperature-resistant and abrasion-resistant

nonmetallic material, and is able to function without lubrication

for a long time.

n

Compressed air discharges in the air tank. A pressure meter

displays the pressure inside the tank. When the pressure

inside the tank rises to 8 bar, the power is automatically cut off

by the pressure-control switch. When the pressure inside the

tank lowers to 6 bar, the power is turned back on by the

pressure-control switch. This gradually raises the pressure in

the air tank. This procedure happens repeatedly.

Assembly

1.

Connect your air supply hose to the the quick-connect

coupling.

2.

Make sure the drainage valve is off and that the pressure

switch is in the OFF position.

3.

ensure that the power supply you are going to use is operating

normally.

4.

Insert the power supply cord into the power supply socket.

DANGER

There is a danger of electric shock.

Use only undamaged electrical cords.

DO NOT touch bare wires or receptacles.

DO NOT operate air compressor in wet weather or in

wet conditions.

DO NOT touch air compressor or cords if hands or

feet are wet.

Ensure that all cords are free of damage before

connecting to the power supply.

Ensure that you have a sufficient electrical supply for

supporting the requirements of the motor.

SHOCK

Use caution when using extension cords.

Use an extension cord which is no more than

25 feet long and at least 14 gauge.

Using an excessively long or thin-wired extension

cord will cause severe damage to the motor.

Use only a 3-wire extension cord that has a 3-blade

grounding plug.

CAUTION