Description

:

The s

turdy constru

cti

on and compact design makes this products the ideal choice for both amateur

and professional.

Designed for many applications including

spray painting and

casting.

An air compressor, air hose and fluid hose

can be

needed to operate this tool.

Safety Guidelines

:

This manual contains informa

ti

on that is important for you to know and understand.

This informa

ti

on

is for your

protec

tion and

sa

fety.

Improper

use, operation or maintenance of this

product could result in injury or property damage.

Please

Read and understand all warnings and opera

ti

ng instru

cti

ons before use. Save these instru

cti

ons.

Warning!

Over pressuriza

ti

on can result in explosion.

Max:

8

0 PSI

1.

Exceeding the Maximum pressure in

the tank can

cause the tank to over pressurize and explode

resul

ti

ng in serious injury or property damage. Always make sure that equipment connected

to tank or hose outlet has a higher pressure ra

ti

ng than the regulated air pressure in the

tank.

Warning!

Risk of tank explosion.

1.

Modi

fi

ca

ti

ons to the tank’s design or constru

cti

on could weaken it. Assemble tank

components in accordance with the service instru

cti

ons. Do not drill into tank, or weld

a

tt

achments, or alter its design in any manner.

2.

Subs

ti

tu

ti

on of unauthorized non-standard components could weaken tank or cause

component failure. Use only those components furnished with the tank. Assembled in

accordance with instru

cti

ons in the service literature.

3.

Damage to the tank or its components could weaken the tank. Never a

tt

empt to repair a

damaged tank . Replace it with a new one.

4.

Improper cleaning or maintenance could block air passages to the safety valve, gauge or

outlet, allowing pressure to rise to dangerous levels , and preven

ti

ng the lowering of tank

pressure.

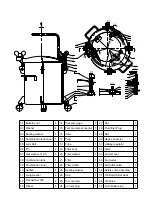

Item No.

365C

Max

Pres

ssure:

80

PSI

Capacity:

5 Gallon

Air Input:

1/4”

Fluid Output: 3/8"

Exterior: 16"W & 24 1/2" H

Inner

:

13"W & 14 3/4" D

Summary of Contents for 365C

Page 7: ......