4

Operation:

1.

Before

fi

lling the tank with material, thoroughly mix and strain the paint to remove skins or

undissolved par

ti

cles with might otherwise block the

fl

ow of material through the hose and

gun. A

(

5

)

gallon

can

of paint can be set inside the tank instead of pouring the paint into the

tank.

2.

Place lid assembly on tank and hand

ti

ghten tank lid clamp screws.

3.

Shut o

ff

the paint tank regulator by turning T-handle counter-clockwise. Adjust the

compressor regulator to obtain the desired air pressure on the spray gun .

4.

Now adjust the regulator on the paint tank to obtain the desired air pressure for the material.

The higher above the paint tank you are spraying, the more pressure you will need on the

material. Normal opera

ti

ng pressure on the paint tank is

6

0 PSI.

Should you wish to

reduce pressure, simply rotate the T-handle adjus

ti

ng screw counter clockwise un

ti

l the

desired pressure se

tti

ng is obtained. There is no need to trigger the gun in order to bleed o

ff

excess paint pressure.

Warning:

Do not use over

8

0 PSI i

n your tank.

Cleaning:

Warning:

Always shut o

ff

air pressure at source and bleed o

ff

all pressure in the paint

tank by gently pulling safety valve before loosening thumb screw and clamps to remove

lid.

It is very important that the tank, material hose and spray gun be cleaned as soon as the

spray job is

fi

nished. Turn o

ff

the main air supply to the tank. Remove all pressure from the

tank by pulling on the safety valve un

ti

l the pressure bleeds down. Turn the T-handle

adjus

ti

ng screw on the regulator counter-clockwise un

ti

l no spring tension is felt.

Loosen thumb screws,

ti

p clamps back and

ti

p tank lid down to one side. Loosen spray gun

air cap retaining ring about three turns then turn on the air supply. Cup cloth over air cap on

the gun and pull trigger. This will force the material back through the hose. into the tank.

Empty and clean tank and parts which come in contact with the material. Use a suitable

solvent. Pour solvent into the tank. Replace lid and

ti

ghten the thumb screws and clamps and

spray un

ti

l clean solvent appears.

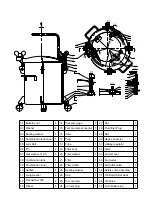

Summary of Contents for 365C

Page 7: ......