Page 18

Page 19

BASIC TROUBLE SHOOTING

Symptoms

Possible Cause

Remedy

No lights on

front of unit

On / Off switch in Off position

Thermal cut-out tripped

Switch to On position

Reset and check for faults

(i.e. scale on thermistor

No boiling water

available

Normal level sensor

holding a signal

Thermal cut-out

tripped (no lights on fascia)

On / Off switch in Off position

Element failed

De-scale

Reset and check for faults

(i.e. scale on thermistor)

Switch to On position

Replace element

Thermal cut-out

trips regularly

Excessive internal scale. (See

‘De-Scale’ )

Faulty wiring to thermistors /

faulty thermistors

Temperature controller needs

adjusting

Element failed to earth

Defective Main Printed Circuit

Board & / or Triac PCB

De-scale the boiler

(Particularly thermistor)

Repair / replace as required

Lower operating temperature

Replace element

Replace Circuit Board & Triac

(sold as a matched pair)

Overflows

Dirt in solenoid valve.

Level sensors require de-

scaling or replacing

Main Printed Circuit

Board faulty

Clean solenoid filter / or replace

solenoid, “work the boiler” -

see Service Instructions

De-scale / replace sensors

Replace Main Printed Circuit

Board

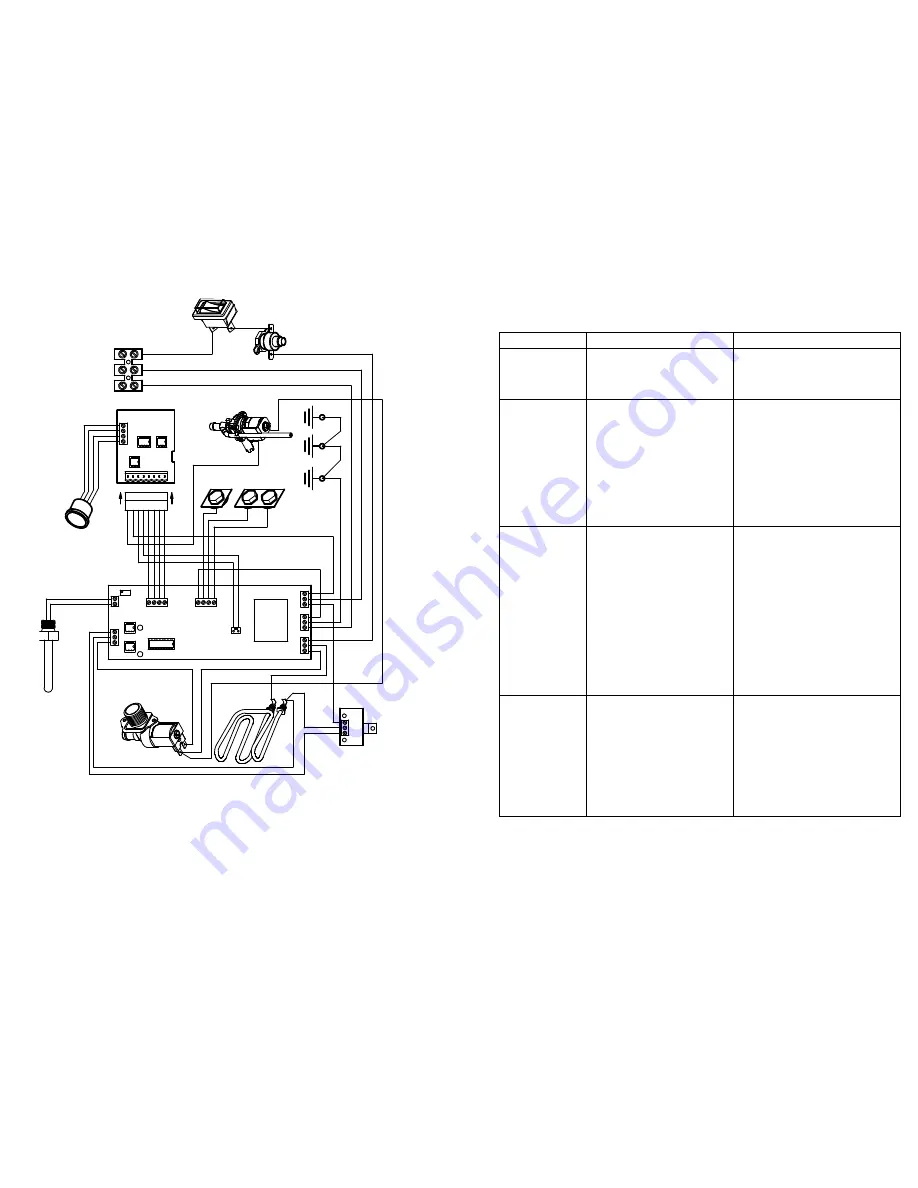

Wi

rin

g

S

c

he

m

at

ic f

or

Ca

lom

a

x Q

uas

ar

2

W

at

er

B

o

ile

r

RE

D

YEL

L

O

W

BL

AC

K

BL

U

E

PI

N

K

BR

O

WN

OR

A

NG

E

WH

ITE

+1

2

Vd

c

(

B

RO

W

N)

BL

AC

K

RE

D

0.

75

mm

Y

E

LL

OW

0.

75

W

H

IT

E

O

R

0

.5m

m

Y

E

LL

OW

BL

AC

K

BL

AC

K

RE

D

N

E

L

BLUE

BLUE

L

N

E

BLACK

YELLOW / GREEN

BL

AC

K

BL

AC

K

YEL

L

OW

/ G

R

EE

N

RED

0V

d

c (

OR

A

NG

E

)

RE

D

RED

OR

A

NG

E

YEL

L

O

W

RE

D

BL

U

E

CONNECTOR PLUG

CO

L

D W

AT

E

R I

NL

E

T

SO

L

EN

O

ID

V

AL

VE

EL

EM

EN

T

TR

IAC

PC

B

HI

G

H

NO

RM

AL

LO

W

LE

V

EL

SEN

SO

RS

HO

T

W

A

TE

R

O

U

TL

E

T

DI

S

PE

N

SE V

AL

VE

HE

A

TE

R

LE

D

SO

L

EN

O

ID

LE

D

TH

E

RM

IST

O

R

PU

SH

B

U

TTO

N

ON

FR

O

NT

PAN

EL

TH

E

RM

A

L

CUT

O

UT

EAR

T

H

ON

BO

D

Y

EAR

T

H

ON

BA

S

E

OR

A

NG

E

BR

O

WN

OP

T

1

U1

OP

1

EAR

T

H O

N

CA

S

IN

G

SI

N

GL

E

P

O

LE

IS

O

LA

T

IN

G

SW

ITC

H