Page 8

Page 9

CLEANING

•

Hold a cup below the dispense valve or place large vessels on the

drip tray. Care must be taken to avoid injury through splashing or

over-filling.

•

To begin filling, press the dispense button and water will flow from

the outlet nozzle.

•

To stop filling, release the dispense button.

NEVER PASS YOUR HAND BENEATH THE NOZZLE.

•

Please retain these instructions for future reference

•

Ensure that a suitable drip tray (such as the one supplied) is

positioned below the dispense valve. This will help keep the

surrounding work surfaces and floor free from drips or splashes.

Various options are available and are outlined on the Accessories

page of this booklet.

•

All de-scaling and servicing must be performed by a suitably

qualified engineer.

GENERAL NOTES

GENERAL OPERATION

Avoid using any abrasive materials. Wiping the outer casing

with a damp cloth should be sufficient. Some stainless

steel cleaning products may not be suitable for plastic and

must not come in contact with the plastic fascia. Always

disconnect the electrical supply before cleaning.

NEVER USE A SPRAY JET OR ANY OTHER METHOD WHICH COULD

CAUSE WATER TO ENTER THE ELECTRICAL CHAMBER.

phenomenon and some de-scaling may be required within the first 12

months. This is not covered under the product warranty as it is not a

fault. If the water supply contains excessive solids in suspension it is

recommended that a fine mesh ‘in-line’ water filter is fitted in the pipe

work after the stop cock.

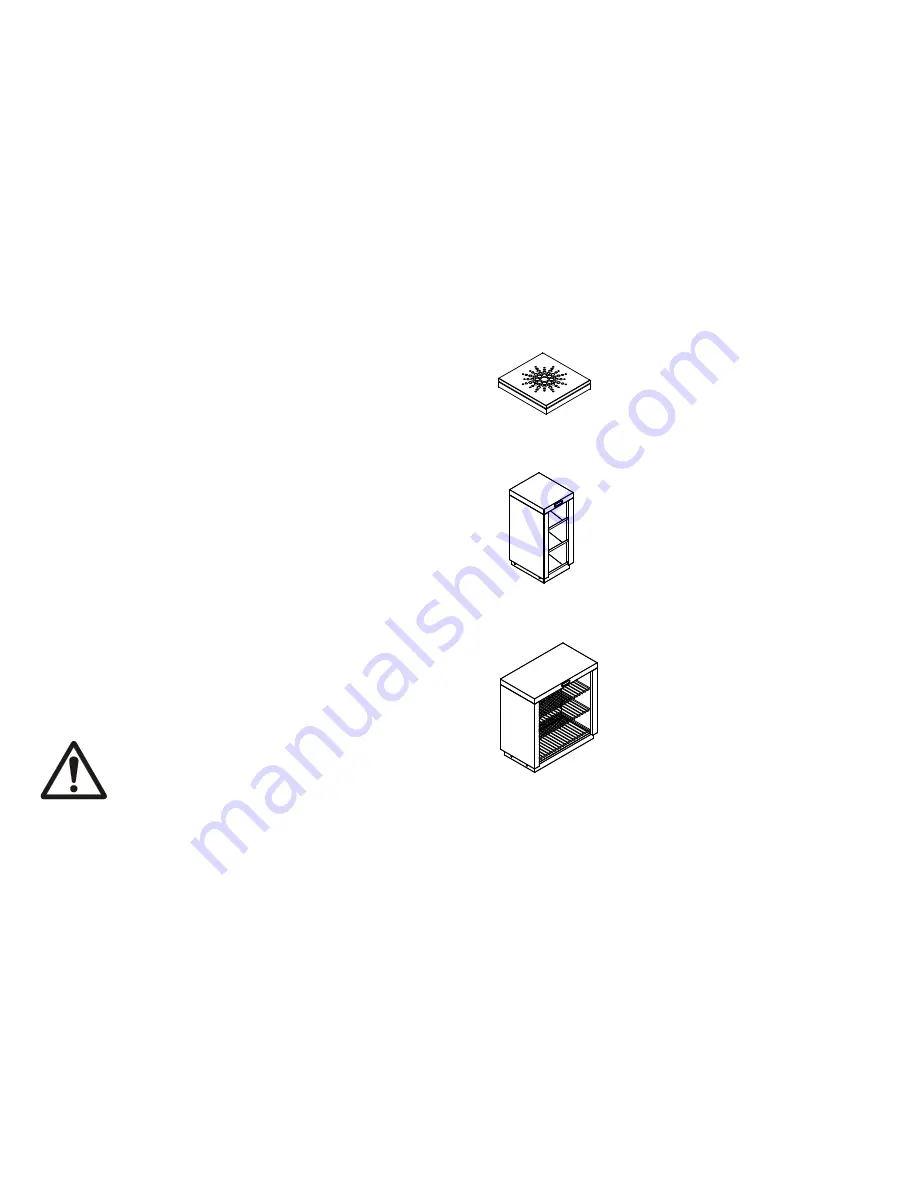

Accessories

Worktop-mounting Stainless

Steel drip tray

Ref. HSSDTK

(freestanding)

Ingredient caddy

Ref. IC3 (3 bay)

-

as shown

Shelf unit

Ref. SHU

IC4 (4 bay)

HSSDTWDK

(with drain outlet)