Page 10

Page 11

When the green service indicator light on the front of the boiler is

showing solid colour, the machine has been starved of water for in

excess of 20 minutes and the solenoid valve has been disabled to

prevent damage to the solenoid coil through overheat. To re-energise

the solenoid, the unit must be disconnected from the electrical supply

and then switched back on, after first reinstating the water supply.

If the unit requires servicing the service indicator will flash a sequence

of light pulses . A 2x or 3x-light pulse generally indicates that the low

or normal level probes require de-scaling.

A 4x-light pulse means the water level has reached the high level

sensor and the likelihood is that the normal level sensor requires

de-scaling, or the machine has over-filled due to debris trapped in

the solenoid valve. The debris can be removed by drawing plenty of

water from the dispense valve, causing the solenoid valve to operate

and flush out the obstruction. The machine will reset itself once the

problem has cleared. If this does not rectify the problem, turn off the

water supply and remove the flexible hose to check for debris in the

valve’s filter. The unit can be used normally while the service indicator

is flashing a 4x pulse. For further assistance, contact our service

department on 0113 249 6681, e-mail service@calomax.co.uk or find a

local service engineer at www.calomax.co.uk

Once the outer casing is removed, access to the Service Area has

been gained. This access must be restricted to persons having

knowledge and practical experience of the appliance, in particular

as far as safety and hygiene are concerned.

De-scale

To gain access to internal components, the body lid must be removed.

The lid incorporates a condenser mechanism which must be fitted the

correct way round. The lid is labelled accordingly. To remove the lid,

break the lid gasket seal and pull the lid forward and up, to the front of

the machine before lifting it clear of the body.

SERVICE INSTRUCTIONS

CONTINUED ON PAGE 14

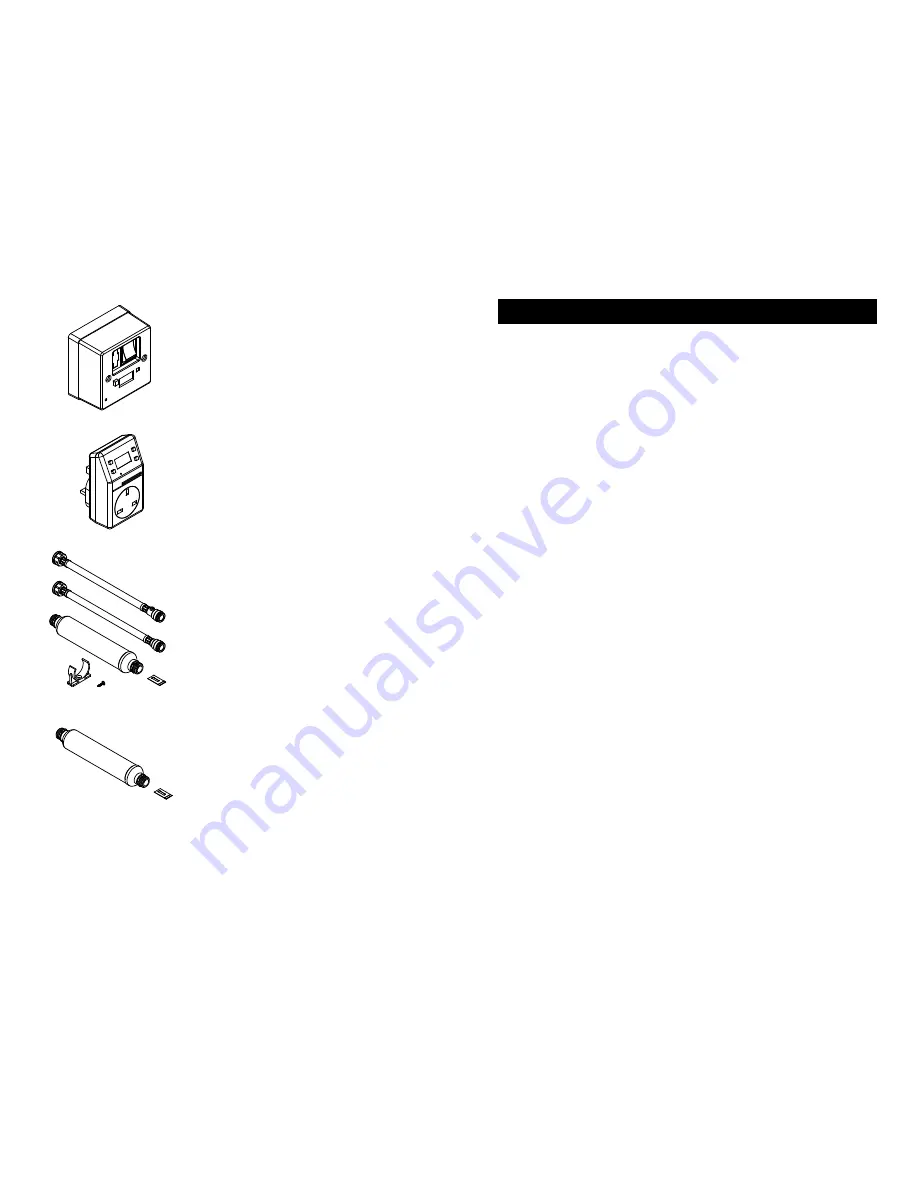

Plug-in time switch

Ref. 7DPIT

Max 3kW

Water filter kit

(To reduce taste & odour problems)

Ref. 10TOSCK

Ref. 10TOSC

(Filter & timestrip replacement for

kit shown above)

For more information visit our website at www.calomax.co.uk or call 0113 249 6681

Fused spur time switch

Ref. 7DFST

Max 3kW