37

1002594 ISSUE 1 M172 VARIHEAT

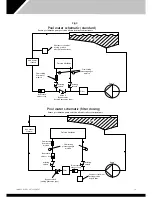

3.4 PLUMBING INSTALLATION

The Variheat should be connected as shown in section 3.0.

If an existing heater is being retained then the Variheat should be connected

between the filter and the existing heater.

Pool water connections on the machine are 1" BSPM stubs.

The unit is supplied with two off each of the following PVC fittings:

1" BSPF x 1" M

1”F x 1½" M

1½" x 50mm F

Suitable breakable couplings, isolation, and drain down valves should be

installed in the pool water inlet/outlet pipes local to Variheat unit.

The heat exchanger in the Variheat will, on small pools, take the full flow rate

of the recirculation system. On larger pools a bypass or separate auxiliary

pump may be necessary. This method can also be used to reduce energy

consumption, by the installation of a two speed or auxiliary pump by-passing

the main pump/filter to satisfy pool water heating and dehumidification

without the need for the main pump to be running.

When the pipework installation is complete the circulating pump should be

switched on and the system checked for leaks. Also check the filter gauge to

see that there is not excessive back pressure.

A filter or magnetic trap needs to be in the boiler circuit to prevent the heat

exchanger in the Variheat from blocking up.

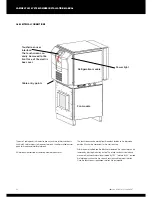

Condensate drain

The condensate driptray in the Variheat collects the water removed by the

dehumidification process, It is therefore necessary to ensure that the Variheat

is placed on a level plinth so that the condensate can run away and not

overflow the edges of the driptray inside the machine.

All Variheat AW models have a ¾" BSPM threaded condensate drain

connection. The drain pipe should run away with adequate fall to waste ie ½"

per foot min. and must incorporate a ‘U’ trap and tun dish.

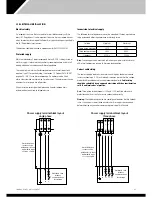

LPHW plumbing

The LPHW connections for connecting the boiler water flow and return to the

Variheat are:

¾" BSPM on AW600/900

1" BSPM on AW1200/1500

Suitable breakable couplings, isolation, and drain down valves should be

installed in the boiler water flow and return pipes local to the Variheat.

Water and air LPHW circuits inside the Variheat should be bled for air pockets.

(Bleed valves fitted internally).

A filter or magnetic trap needs to be in the boiler circuit to prevent the heat

exchanger in the Variheat from blocking up.

Refer to the boiler manufacturers instructions before designing the pipework

system.

Important general points

1. Do not route water pipes across service access panels or air inlet/outlets.

2. The water circuits to and from the Variheat should be capable of

maintaining the specified water flow required.

3. All pipe work must be adequately supported with allowance for

expansion and contraction especially with regard to the plastic pipe work.

4. It is recommended that when installing water systems the last

connections to be made should be adjacent to the Variheat III to avoid

undue stresses on the unit connections.

5. All pool purifying devices and chemical injection systems must be

fitted down stream of the Variheat with a non-return valve to prevent

concentrated chemicals back feeding into the heat exchangers.

6. The practice of dosing chemicals direct into skimmer basket must not

be allowed as this would result in concentrated corrosive liquids passing

over vulnerable metal components.

7. Water quality must be maintained not only relating to solids, etc but

for pH between 7.4 - 7.8, and if pool water is saline at a maximum

concentration of 8mg/litre.

8. See warranty exclusions on page 70. for total list of water quality

limits.

Summary of Contents for Variheat AW600

Page 2: ......

Page 55: ...55 1002594 ISSUE 1 M172 VARIHEAT...