The manufacturer of this product agrees to repair or replace designated parts that prove defective within the war-

ranty period listed in the chart below. Specific limitations and exclusions apply. This warranty covers defects in material and

workmanship and not failure due to normal wear, depreciation, abuse, accidental damage, negligence, improper use, main-

tenance or storage. To make claim under the terms of the warranty, all parts said to be defective must be returned to a des-

ignated Warranty Service Center for warranty inspection. The judgments and decisions of the factory-authorized personnel

concerning the validity of warranty claims are final.

Many components are covered by warranties given by their respective manufacturers. These warranties pass through to the

end user. As a factory authorized and trained warranty service center the factory will honor the terms of all component

warranties and satisfy claims of the appropriate warranty provisions.

Normal wear items include but are not limited to: hoses, nozzles, filter, valves, seals and are not covered by this warranty.

This warranty is in lieu of all other warranties, express or implied, including without limitation any warranties of

merchantability or fitness for a particular purpose and all such warranties are hereby disclaimed and excluded by the

Manufacturer. The Manufacturer's warranty obligation is limited to repair and replacement of defective products as provid-

ed herein and the Manufacturer shall not be liable for any further loss, damages or expenses, including damages from ship-

ping, accident, abuse, acts of God, misuse or neglect. Neither is damage from repairs using parts not purchased from the

Manufacturer or alterations performed by non-factory authorized personnel. Failure to install and operate equipment

according to the guidelines put forth in the instruction manual shall void warranty.

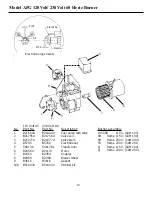

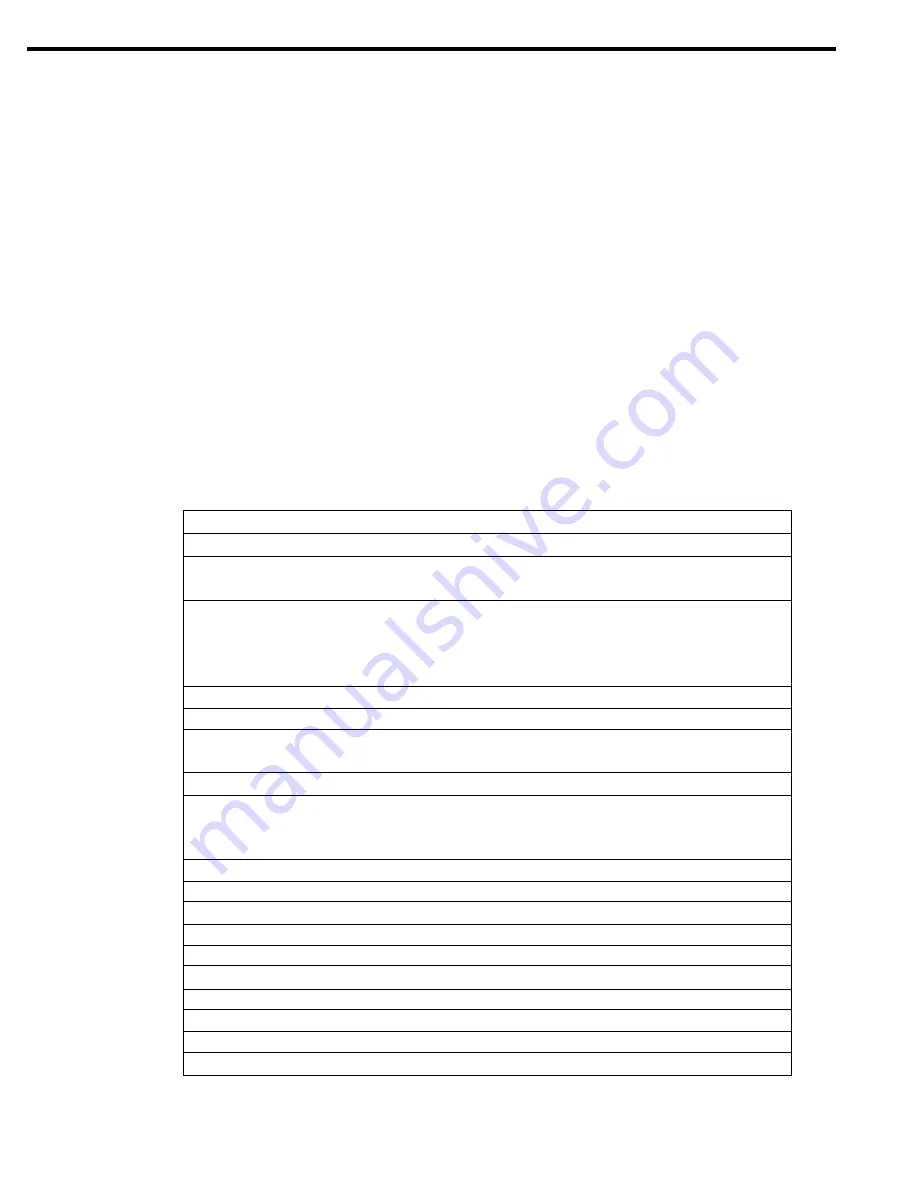

Manufacturer

Warranty Period and Details

AR Pump

2 year 1 year on Pump/Motor units

Cat Pump

5 year on 2SF and 4SF models

2 year on 5DX models

General Pump

5 year on pumps

Lifetime on brass manifold against freezing

1 year on the aluminum manifold

1 year on Pump/Motor units

Udor Pumps

5 year

Briggs and Stratton

1 year on standard engines

2 year on Intek and Vanguard products

Hatz Diesel Engines

1 year

Honda Engines

2 year on GX series Engines

2 year on GC products for personal use

90 days on GC products in commercial use

Robin Engines

2 year

Baldor Electric Motors

1 year from date of purchase

Leeson Electric Motors

1 year from date of purchase

Burners

1 Year from date of purchase

Hot Water Coils

5 year from date of purchase

Machine Frame

1 year from date of purchase

Accessories

:Includes tips, guns, wands, hoses, injectors, unloaders, sandblasters, flat surface cleaners, hose

reels, turbo nozzles, drain nozzles, brushes, foamers, GFCI units, thermal relief, filters, tanks, etc. 90 days

Statement of Warranty