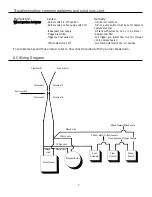

Troubleshooting: common problems and solutions

Cause

-Switch in ‘off’ position

-Machine not plugged in

-GFCI tripped

-Overload on motor tripped

-Circuit breaker tripped

-Water supply not turned on

-Plugged nozzle on wand

-Trigger gun off or malfunctioning

-Plugged spray nozzle

-Inlet screen is plugged

-Insufficient water supply

-Unloader valve stuck open

-Plugged inlet or discharge hose

-Use of additional lengths of hose

-Partially plugged spray nozzle

-Worn nozzle

-Soap (low pressure tip installed)

-Restricted or leaking water hose

-Cavitation (inadequate water supply)

-Worn pump packings

-Fouled inlet or discharge valves

-Broken valve spring

-Worn or restricted unloader valve

-Restricted discharge

-Valve on gun/wand not open

-Injector valve not turned on

-Discharge hose too long

-Clogged injector pick-up hose

-Clogged injector

-Worn plungers or packings

-All valves fouled

-Unloader valve seat fouled

-Leak in trigger or discharge

-High humidity or direct water spray

-Worn seals

Malfunction

PPrreessssuurree w

waasshheerr w

wiillll nnoott rruunn

U

Unniitt rruunnss bbuutt nnoo w

waatteerr ddiiss-

cchhaarrggeess

LLoow

w nnoozzzzllee pprreessssuurree

SSuurrggiinngg pprreessssuurree oorr ddrroopp iinn

pprreessssuurree

PPrreessssuurree aatt ppuum

mpp bbuutt lloow

w ddiiss-

cchhaarrggee pprreessssuurree aatt gguunn

C

Chheem

miiccaall iinnjjeeccttoorr nnoott w

woorrkkiinngg

pprrooppeerrllyy

W

Waatteerr lleeaakkss ffrroom

m ppuum

mpp m

maannii-

ffoolldd

U

Unnllooaaddeerr ddooeess nnoott bbyyppaassss

U

Unnllooaaddeerr ccyycclleess w

whheenn gguunn iiss

sshhuutt ooffff

W

Waatteerr iinn ccrraannkkccaassee

Remedy

-Turn switch to ‘on’ position

-Plug machine into adequate service

-Reset GFCI

-Allow automatic overload to cool or push the

reset button located on motor to reset

-Reset circuit breaker in main panel

-Turn on water supply

-Remove, clean, or replace nozzle

-Remove, repair, or replace trigger gun

-Remove nozzle and clean or replace

-Remove filter and clean or replace

-Secure adequate water supply

-Disassemble and clean; repair or replace

-Flush or replace hoses

-Reduce discharge hose length.

-Remove nozzle and clean or replace

-Remove and replace nozzle

-Remove and install one of the nozzles

-Check inlet hose and filter; clean or replace

-Secure adequate water supply

-Inspect and replace worn packings

-Inspect valves and clean or replace

-Inspect and replace valve spring

-Inspect unloader and repair or replace

-Check for discharge obstructions in injector,

hose, wand, and unloader

-Open valve by turning forward handle counter-

clockwise. (see wand breakdown page 10)

-Turn on injector by turning fitting on injector

-Reduce hose length or reposition injector to

within forty feet of trigger gun

-Remove and clean or replace

-Disassemble, clean, and reassemble

-Inspect and replace

-Inspect valves and clean or replace

-Inspect and clean or replace

-Inspect leaking fittings and repair or replace

-Reduce oil change intervals

-Replace seals

Despite the complexity of your power washing equipment, a number of common complaints stem from rela-

tively simple problems. With guidance, the user can identify and remedy many common problems.

Always disconnect the power supply before attempting to service any equipment.

6