Chapter 4: Preparing for installation

194

Best Pract ices for Cabling

The following practices are essential to the reliability and longevity of cabled connections:

l

Use only shielded cables to resist interference.

l

For vertical runs, provide cable support and strain relief.

l

Include a 2-ft (0.6-m) service loop on each end of the cable to allow for thermal expansion and

contraction and to facilitate terminating the cable again when needed.

l

Include a drip loop to shed water so that most of the water does not reach the connector at the

device.

l

Properly crimp all connectors.

l

Use dielectric grease on all connectors to resist corrosion.

l

Use only shielded connectors to resist interference and corrosion.

W iring Connect ors

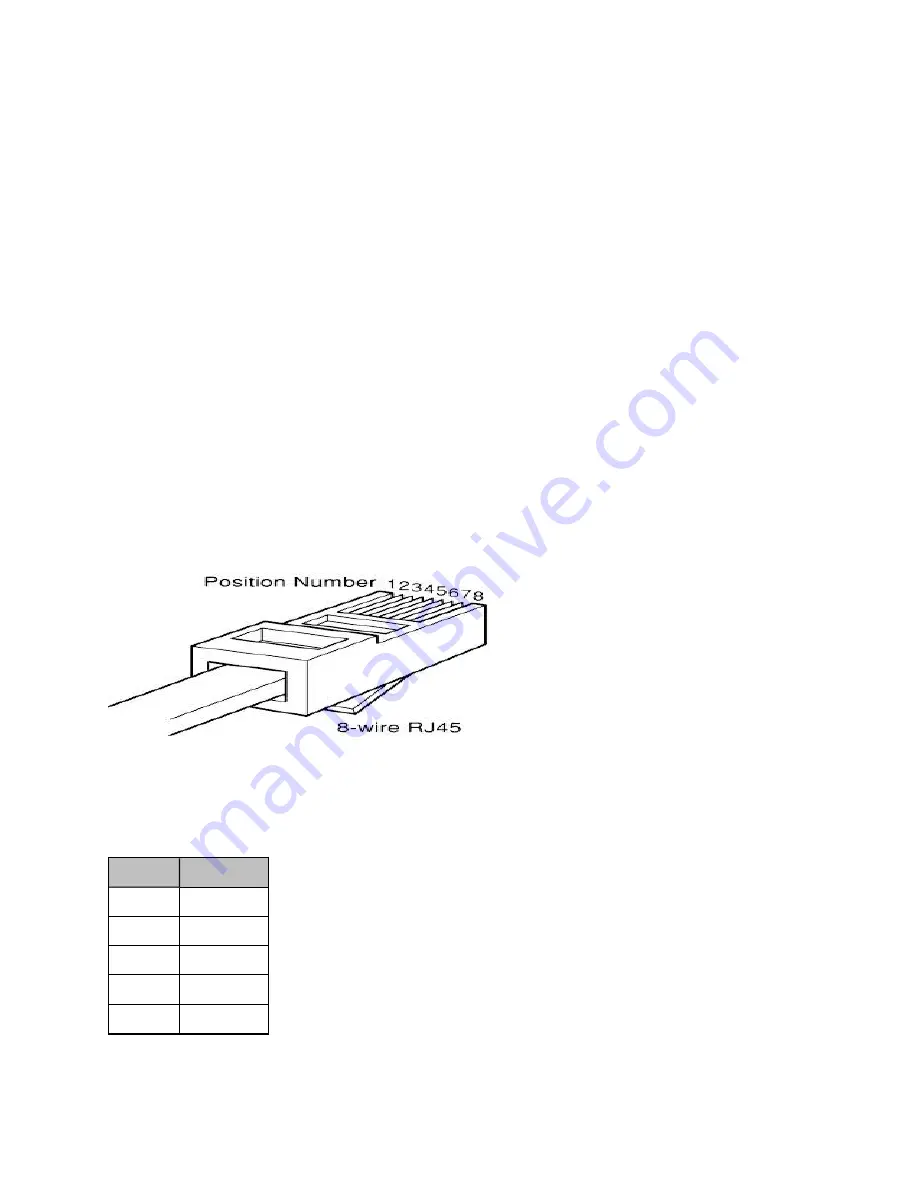

The following diagrams correlate pins to wire colors and illustrate crossovers where applicable.

Pin 1, relative to the lock tab on the connector of a straight-through cable is located as shown below.

Figure 74 :

Pin 1 location

Main port pinout

Table 118 : Main port pinout

RJ45 pin Description

1

+TxRx0

2

–TxRx0

3

+TxRx1

4

+TxRx2

5

–TxRx2

Summary of Contents for PMP 450 Series

Page 92: ...Chapter 2 System hardware 92 Figure 29 MicroPoP Omni antenna implementation pattern Vertical...

Page 134: ...Chapter 3 System planning 134 Figure 51 Mast or tower installation...

Page 135: ...Chapter 3 System planning 135 Figure 52 Wall installation...

Page 136: ...Chapter 3 System planning 136 Figure 53 Roof installation...

Page 137: ...Chapter 3 System planning 137 Figure 54 GPS receiver wall installation...

Page 158: ...Chapter 3 System planning 158 Figure 61 cnMedusa Antenna...