S-Series Technical Manual

55

Cambridge Air Solutions

positive shut-off high pressure regulator must be

added upstream of the heater’s individual low

pressure manual shut-off valve. If a high pressure

regulator is needed and has not been installed, check

with your local agent or Cambridge Air Solutions'

Customer Service Group at 1-800-473-4569 to

determine the size and capacity requirements.

m

WARNING:

When disconnect switch is activated with

enclosure open, live power is present. Only

experienced technicians with knowledge and

respect for live power should proceed beyond this

point.

4. BLOWER ROTATION CHECK

a. Open the access door on the electrical control

enclosure side and turn the disconnect switch to the

”ON” position.

b. Turn the blower service switch to the ”LOCAL”

position. Blower motor will start after the

motorized damper opens. Then, turn the blower

service switch to the ”OFF” position and verify

the blower is rotating clockwise from the control

enclosure side.

IMPORTANT

On a three phase system, the rotation direction of the

blower may be reversed by switching any two wires

located on the downstream side of the motor starter.

The electrical supply to the heater must be turned off

prior to switching the wiring.

IMPORTANT

Indications of loose belts include barking or

squealing when the blower starts. If these

symptoms occur, please refer to the Belt Tensioning

instructions (page 45)

IMPORTANT

The damper will remain in the open position as

long as the blower service switch is not returned to

the ”REMOTE” position or the Low Temperature

Cutout (LTC) function has not timed out.

5. MOTOR AMP DRAW CHECK

IMPORTANT

The heater access doors must be closed for this test.

a. Turn the blower service switch to the ”LOCAL”

position and let the motor warm up.

b. Check motor current at the overload on all three

legs.

c. Turn the blower service switch to the ”OFF”

position.

IMPORTANT

The average amps must not exceed 103% of the

Motor Nameplate FLA. High amperage may indicate

excessive blower RPM.

6. BURNER MANIFOLD PRESSURE

ADJUSTMENT

a. Turn the disconnect switch to the “OFF” position.

b. Drive the modulating valve to fully open.

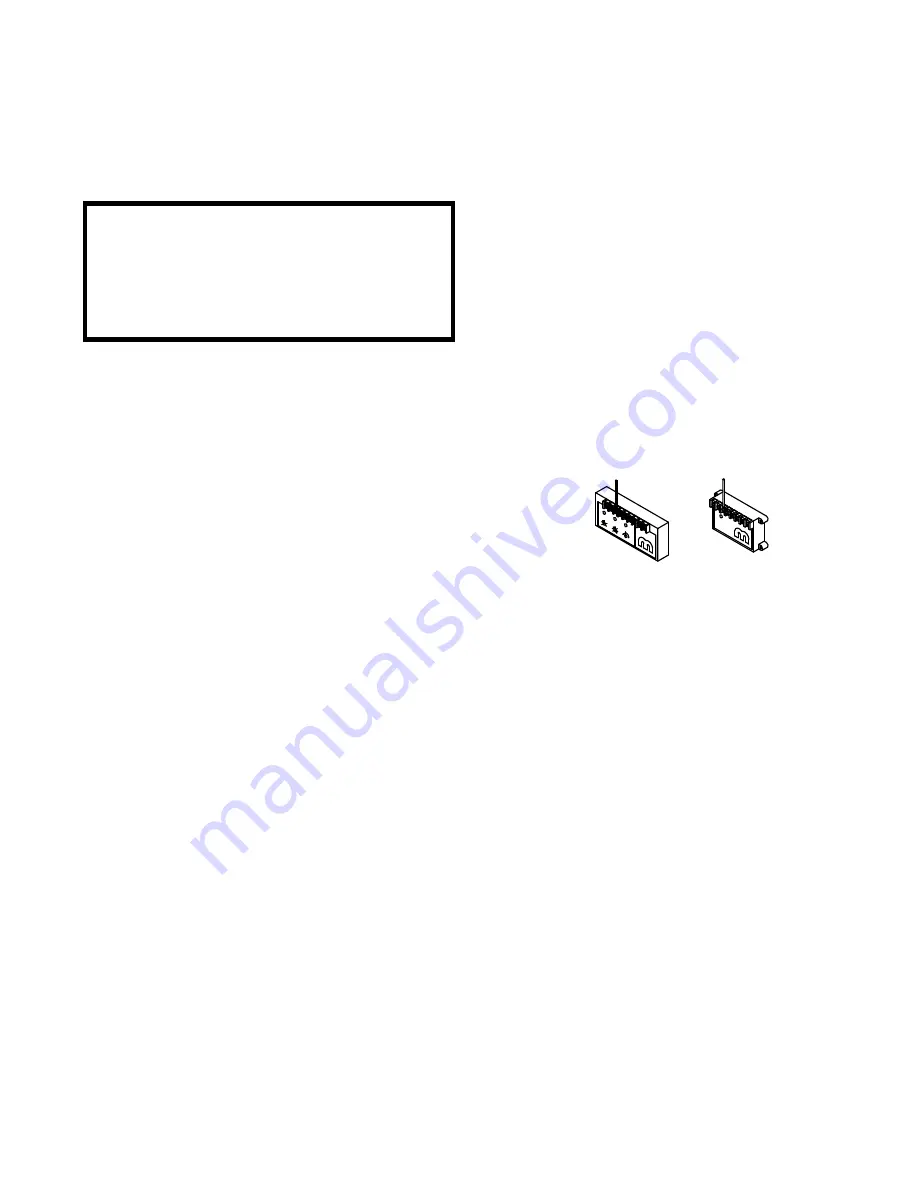

b.1 For EDL, EDR, EDSM, and EDSM/TP control

systems, remove the wire from terminal #3 on the

amplifier (see Figure 1).

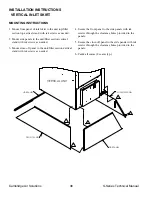

Figure 1

b.2.a. For EDSC control systems, remove the wires from

terminals #T1 and #T2 of the amplifier and connect

an 1100 Ω resistor across terminals #T1 and #T2 of

the amplifier

OR

Remove the discharge temperature sensor from the

discharge duct.

b.2.b. Provide a control signal (4-20 mA / 0-10 VDC) to the

amplifier by setting the signal level thru the Building

Automation System

OR

Remove the wires from terminals #5 and #6 of

the amplifier and connect a current/voltage signal

generator to terminals #5 and #6 of the amplifier.

(Note polarity of the terminals: #5 is negative and #6

is positive)

b.2.c. Set the modulation level to 100% (20 mA / 10 VDC).

c. Remove the 1/8" plug from the manual shut-off valve

located just prior to the burner, and connect a manometer

for the purpose of measuring the manifold pressure.

d. Refer to the heater nameplate for the Manifold

Differential Pressure (MDP) and record below.