D--9--610 Page 11

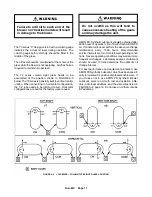

Failure to add oil to each end of the

blower on 70 series models will result

in damage to the blower.

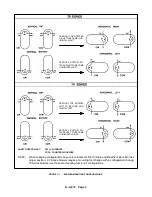

The 70 series “C” design version with a column gauge

indicates the actual oil level during operation. The

column gauge before start--up should be filled to the

middle of the glass.

The oil level should be maintained at the center of the

glass while the blower is not operating. Add fresh oil as

required to maintain proper level.

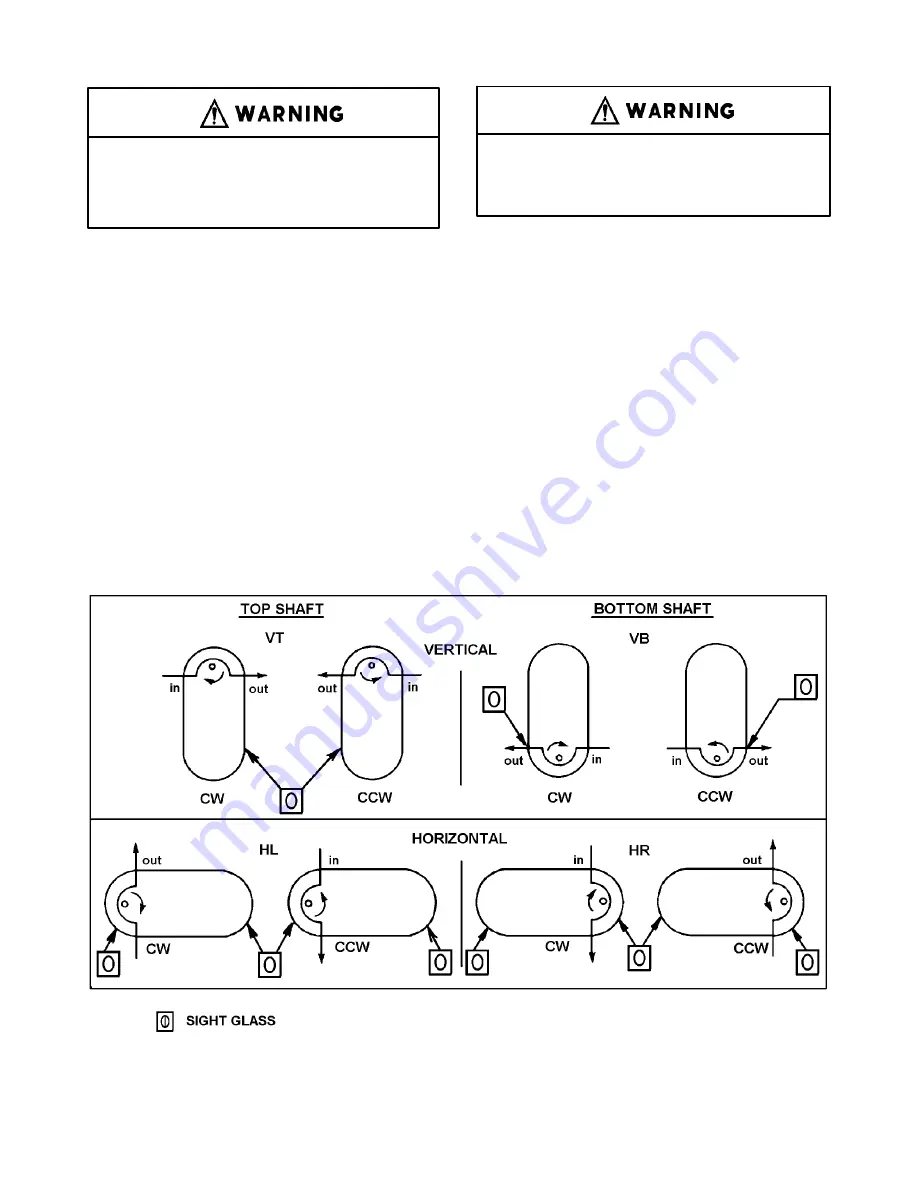

The 70 series column sight glass needs to be

assembled at the position shown in FIGURE 3--3

below. The 70 series is generally built to vertical config-

uration. When converting to horizontal configuration,

the 1/4” tube needs to be trimmed to suit. Horizontal

configurations are built at the factory upon request

Do not overfill as this will tend to

cause excessive heating of the gears

and may damage the unit.

AEON PD Synthetic Lubricant should be drained after

6000 hours of operation. Re--fill with fresh AEON PD

oil. If mineral oil is used, perform the above oil--change

maintenance every 1500 hours. Recommended

service intervals are for normal blower operating condi-

tions. Severe operating conditions may warrant more

frequent oil changes. Laboratory analysis of lubricant

should be used to help determine the optimum oil

change interval.

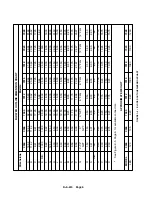

For best performance and equipment protection, use

AEON PD Synthetic Lubricant, which has been specifi-

cally formulated for positive displacement blowers. If

you choose not to use AEON PD Synthetic Blower

Lubricant, select an oil with rust and oxidation inhib-

itors, anti--foam additives, and the viscosities listed in

FIGURE 3--4, page 13. Do not use an oil that contains

EP additives.

FIGURE 3--3 -- 70 SERIES -- COLUMN TYPE SIGHT GLASS LOCATION