Page 8 of 13

WC16PS SERIES RESTROOM CONTROL

INSTALLATION INSTRUCTIONS

CONNECTIONS

OPERATIONS

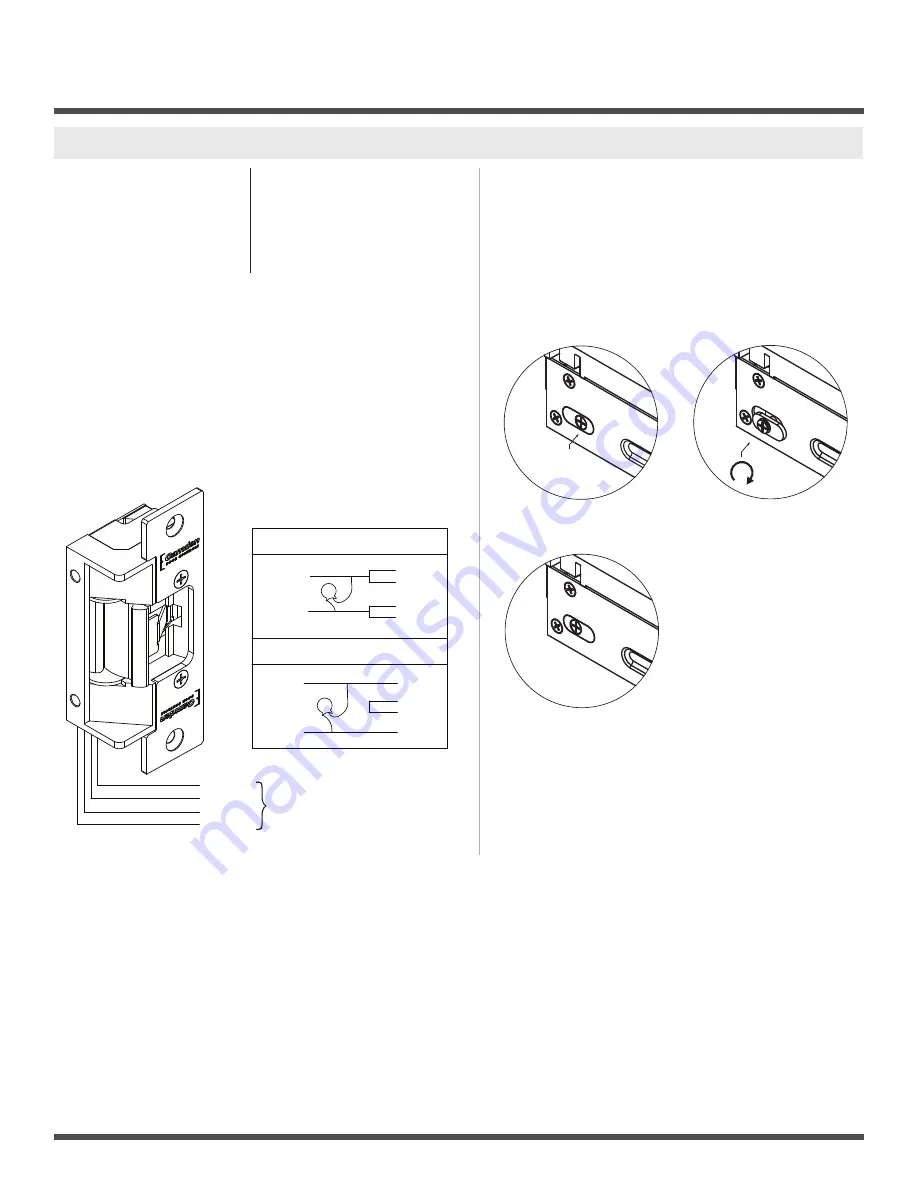

CX-ED2079 ‘Universal’ Electric Strike

Red

Black

Blue

Green

Black

Red

Blue

Green

Black

Red

Blue

Green

(+12V)

( - )

(+24V)

( - )

12V

24V

Varistor

Varistor

Power

Power

5. Connections

6. Operation

POWER

12VDC

Red/Black: +12V

Blue/Green: Ground

A varistor is provided to protect/prevent strike from spikes.

Connect varistor between input wires.

Fail Safe

Changing

Fail Secure

24VDC

Red:

+24V

Black/Blue:

-

Green:

Ground

How to modify fail-safe to fail-secure or vice versa.

1. Loosen the screw as per the product diagram below.

2. Rotate the set plate 180° and slide the plate until it

is properly seated.

3. Tighten the screw.

Note: For UL 294 / UL 1034 compliance the door strikes

are to be powered via a UL 294/ UL 603 class 2 power

limited output from a control panel and or power supply.

Furthermore, when powered by AC/DC the units shall use a

UL regulated UL 294/ UL 603 power limited class 2 output

rated 12/24V with AC on indicator.