Page 4 of 9

WC17PS SERIES RESTROOM CONTROL

INSTALLATION INSTRUCTIONS

Page 3 of 9

WC17PS SERIES RESTROOM CONTROL

INSTALLATION INSTRUCTIONS

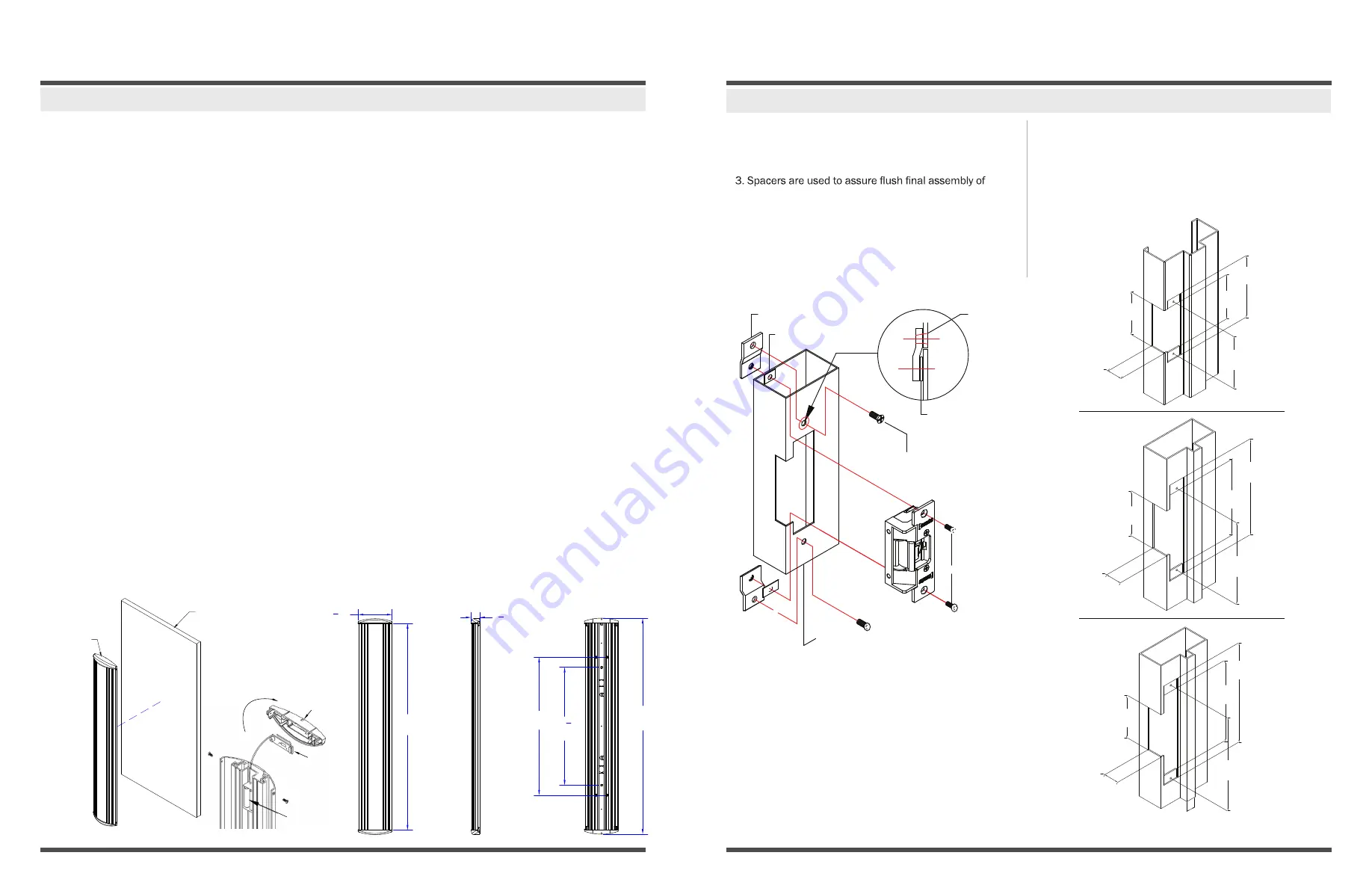

5. CX-ED2079 'UNIVERSAL' ELECTRIC STRIKE INSTALLATION

CX-ED2079 ‘Universal’ Electric Strike

1. Prepare the door jamb as per the appropriate drawing.

2. Install mounting brackets to jamb using M5x12 screws

and pressed metal nuts. Do not tighten.

faceplate into jamb. Add one of more spacers between

jamb and mounting bracket when face plate extends

beyond the jamb. When the faceplate sits inside the

jamb, spacers must be added between the mounting

bracket & the lip bracket. Make sure clearance hole in

spacer aligns with hole in mounting bracket.

4. Connect wires coming from the low voltage side of the

transformer to wires (black) from strike.

5. Install electric strike jamb by attaching with # 10-32

screws and lockwashers.

6. Secure M5x12 screws holding mounting brackets to jamb.

4. Installation

Mounting Bracket

Spacer

Spacer (Option)

Spacer

M5x12 Flat-Head Screw (2pcs)

Jamp

M5x12 Screw

Vertical Centerline

Note: The products are intended to be installed in accordance

with the installation wiring diagram, mechanical assembly

drawings provided with each product, the local authority having

jurisdiction (AHJ) and the National Electric Code, NFPA 70.

When installed in fail secure mode, the local authority shall be

consulted with regard to the use of possible panic hardware to

allow emergency exit from the secure area.

The electric door strike shall be installed in such a way and

in such a location so as to not impair the operation of an

emergency exit device or panic hardware mounted on the door.

(86mm)

3-3/8”

(187mm)

7-3/8”

(36mm)

1-3/8”

(200mm)

7-7/8”

(86mm)

3-3/8”

(86mm)

3-3/8”

(168mm)

6-3/8”

(31mm)

1-7/32”

(31mm)

1-7/32”

(31mm)

1-7/32”

(105mm)

ESP1B + ESP2B

ESP3B

ESP4B

4-1/8”

(124mm)

4-7/8”

(89mm)

3-1/2”

(155mm)

6-1/8”

(173mm)

6-7/8”

(144mm)

5-11/16”

Code Requirements: If installed according to these instructions

the CM-7536 Column switch will meet the requirements of the

California Building Code (Section 1117B.6, Date: 2009), and

Section 3.8.3.3.17(b) of the Ontario Building Code.

Installation Steps:

1. Remove the assembled unit from packaging. The unit must be

disassembled to be installed. To do this, remove the two small

Phillips screws holding the top cap in place.

Remove the cap. Then, grasping the center (metal) actuation bar,

pull vertically until the entire actuation bar is removed

from the base unit. Set the actuation bar aside and protect

from surface damage.

2. Determine the optimum height from the finished floor. See

illustration (above) for common height. If utilizing an in-wall

electrical box, center the backplate over the box, while lining up

the top edge with your mark.

3. Using a level, ensure the base unit is plumb and level, and

mark the 4 mounting locations through the adjustable nylon inset

screws onto the wall surface (if on drywall use a pencil, and if on

concrete a narrow Sharpie or similar).

4. a) Drill the wall at the 4 marked locations, and tap in the

appropriate wall plugs. We supply both drywall and concrete

anchors for the included #14 screws.

4. b) If mounting the Column Switch to an aluminum post or

framing section, drill and tap 4 holes for 1/4”-20 Stainless Steel

Machine screws (also provided).

5. a) If hardwiring: Use the supplied wirenuts to make your

wire connections. Push excess wire into the back box and ensure

cable is not exposed to the moving parts of the switch, or pinched

between the back of the base unit and wall surface.

4) nylon inset screws may be turned in or out to help plump up

Column switch and adjust for wall irregularities. Check with a level.

When satisfied, install the 4 mounting screws and tighten.

Batteries

CM-TX9

End Cap

5. a) If using Lazerpoint RF: The cap includes a snap-in

compartment for our TX-9 transmitter. Place transmitter in the cap,

with the wires hanging down and to the front of the cap. Using the

supplied wirenuts, connect the two activating wires to the Column

switch lead wires. Slide the battery and the extra wiring into the

center (rear) channel provided. Do not slide all of the wire into the

channel, so that the cap can hang off to one side while you perform

the next step.

Using the supplied wirenuts, connect the two activating wires to

the Column switch lead wires. Then, slide the battery and the extra

wiring into the center (rear) channel provided. Do not slide all of the

wire into the channel, so that the cap can hang off to one side while

you perform the next step.

5. b) If using other RF: Using the supplied wirenuts, make your

wire connections to the RF transmitter and tuck the transmitter and

excess wire into the back box (or wall cavity). Ensure cable is not

exposed to the moving parts of the switch, or pinched between

the back of the base unit and the surface of the wall.

6. Reassemble the (center) actuation bar into base unit. This is done

by holding the hanger (located at the top center) vertically ‘up’ – then

carefully sliding actuation bar down the length of the base unit,

being careful not to bend or break the springs or internal switches.

When the bottom edge of the actuation bar reaches the height of

the springs, use your free hand to tuck in the spring and switches

under the actuation bar as it slides over them. When activation bar

is approx 2” from bottom, position hanger so it falls into the slots

provided at the top of the base unit. Slide actuation bar down until

it rests on the hanger. Actuation bar should now move freely within

the base unit. Test the operation of the switch before mounting the

cap.

7. When satisfied with the switch operation, place cap back on top,

and screw in the two small self-tapping Phillips screws.

4. CM-7536 MOUNT INSTALLATION

Wall

CM-7536 Series

With Kinetic Switch

36''

[914mm]

112''

[38mm]

37 1/2''

[955mm]

5 78''

[150mm]

2012''

[521mm]

24''

[610mm]