CX-WC17VR-PS SERIES RESTROOM KIT

INSTALLATION INSTRUCTIONS

CX-WC17VR-PS SERIES RESTROOM KIT

INSTALLATION INSTRUCTIONS

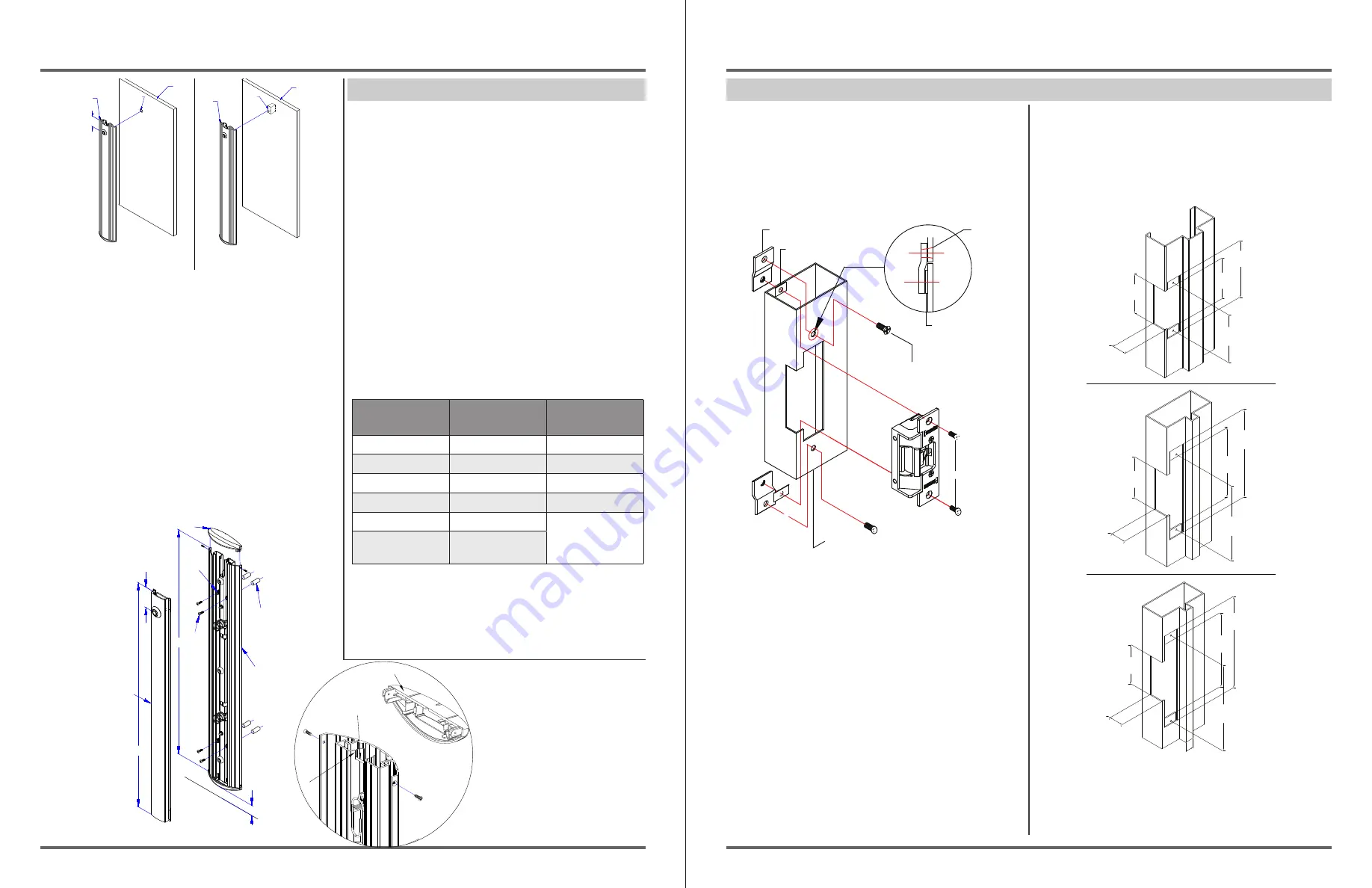

4. CX-ED2079 ‘universal’ electric strike installation

1. Firstly, verify that voltage required to operate Electric strike is compati-

ble with supply voltage of the installation.

POWER: Red/Black, Blue/Green (12 VDC)

Red, Black/Blue, Green (24 VDC)

Red/Green (Sort Black, Blue)

2. Splice the strike wire with the supplied wire and make sure to attach

provided varistor as described in connection section.

3. Make sure that the door jamb has an appropriate cutout to accommo-

date strike assembly. (Make sure to leave enough room for splicing

between power supply and electric strike wiring.)

4. For a wooden door jamb, drill holes to install the strike and finally use

supplied #12 x 1/2” machine screws to secure the strike.

CX-ED2079 ‘Universal’ Electric Strike

1. Prepare the door jamb as per the appropriate drawing.

2. Install mounting brackets to jamb using M5x12 screws

and pressed metal nuts. Do not tighten.

faceplate into jamb. Add one of more spacers between

jamb and mounting bracket when face plate extends

beyond the jamb. When the faceplate sits inside the

jamb, spacers must be added between the mounting

bracket & the lip bracket. Make sure clearance hole in

spacer aligns with hole in mounting bracket.

4. Connect wires coming from the low voltage side of the

transformer to wires (black) from strike.

5. Install electric strike jamb by attaching with # 10-32

screws and lockwashers.

6. Secure M5x12 screws holding mounting brackets to jamb.

4. Installation

Mounting Bracket

Spacer

Spacer (Option)

Spacer

M5x12 Flat-Head Screw (2pcs)

Jamp

M5x12 Screw

Vertical Centerline

Note: The products are intended to be installed in accordance

with the installation wiring diagram, mechanical assembly

drawings provided with each product, the local authority having

jurisdiction (AHJ) and the National Electric Code, NFPA 70.

When installed in fail secure mode, the local authority shall be

consulted with regard to the use of possible panic hardware to

allow emergency exit from the secure area.

The electric door strike shall be installed in such a way and

in such a location so as to not impair the operation of an

emergency exit device or panic hardware mounted on the door.

(86mm)

3-3/8”

(187mm)

7-3/8”

(36mm)

1-3/8”

(200mm)

7-7/8”

(86mm)

3-3/8”

(86mm)

3-3/8”

(168mm)

6-3/8”

(31mm)

1-7/32”

(31mm)

1-7/32”

(31mm)

1-7/32”

(105mm)

ESP1B + ESP2B

ESP3B

ESP4B

4-1/8”

(124mm)

4-7/8”

(89mm)

3-1/2”

(155mm)

6-1/8”

(173mm)

6-7/8”

(144mm)

5-11/16”

Note:

• The products are intended to be installed in accordance with the

installation wiring diagram, mechanical assembly drawings provided

with each product, the local authority having jurisdiction (AHJ) and

the electric code, NFPA 70. When installed in fail secure mode, the

local authority shall be consulted with the regards to the use of

possible panic hardware to allow emergency exit from the secure

area.

• The electric door strike shall be installed in such a way and in such

a location so as to not impair the operation of an emergency exit

device or panic hardware mounted on the door.

Page 3 of 9

Page 4 of 9

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

CAMDEN DOOR CONTROLS. ANY

REPRODUCTION IN PART OR AS A

WHOLE WITHOUT THE WRITTEN

PERMISSION OF CAMDEN DOOR

CONTROLS IS PROHIBITED.

5502 Timberlea Blvd.

Mississauga, ON Canada

L4W 2T7

Tel: (905) 366-3377

www.camdencontrols.com

A.OLISA

24/03/22

CUST

Wave

Swit

ch wire

Cut

-out

Drill

a Ø 0.

250'

' Hole

Wall

In-wall

Elect

rical

Box

Wall

Mounting without in-wall

electrical box

Mounting with in-wall

electrical box

2 1/2'

'

[64.

77mm]

CM-7536VR

Hands-Free

Column™

switch

CM-7536VR

Hands-Free

Column™

switch

4. Using a level tool, ensure the base unit is perfectly levelled and mark 4

mounting locations through the adjustable nylon inset screws onto the

wall surface (if mounting on drywall, use a pencil, and if mounting on

concrete wall, use a narrow sharp object for marking).

5. Drill the wall at the four marked locations and tap in the appropriate

wall plugs. We supply both drywall and concrete anchors for the

included #14 screws.

6. If mounting the Column Switch on an aluminium post or framing

section, drill and tap four holes for 1/4”-20 stainless steel machine

screws (also provided).

7. Connect all the wires coming from the CX-33PS box to the CM-221

sensor.

8. Secure the assembly with the provided mounting screw, and insert

actuation bar which was removed in step 1, and finally secure it with

End cap.

IMPORTANT: Do not apply power to the unit until you

have fully read the instructions and have made the

required adjustments.

The CX-WC17VR-PS Restroom Control Kit comes with the CX-33PS: Advanced

Logic Relay, Power Supply and Cabinet, which has a set of two terminal strips.

Each strip has a clear label for wiring, and it is also pre-wired, which eliminates

the need for a separate wiring manual for the termination point. However, later

sections of this manual include detailed wiring diagrams for reference.

The left-side terminal strip is used to power CX-33PS, the PUSH to OPEN (both

exterior and interior) column switches, PUSH to LOCK column switch, the door

position switch, and the wet trigger. The right switch of the terminal is used to

power the outputs to drive the strike (Relay 1), door operator (Relay 2), LED

light (Relay 3), and provide VDC power for the door strike.

There are six wires from CM-221 needs to be connected with terminal strips:

Wire Color (from

CM-221)

Splicing With

To (CX-33PS)

Red wire

-

+V DC

Black wire

-

-V DC

Yellow wire

-

Green LED

White wire

-

Red LED

Green Wire

Top Switch wire

Inside/Outside Push

to Open and Push

to Lock

Blue Wire

Top Switch wire

IMPORTANT:

The supplied CX-TRX-5024 transformer will have its secondary terminals

wired to the terminals on the top of the left terminal strip marked as “AC”.

Next, wire the primary terminals to the AC feed to be used. Confirm your

connections and apply power by turning on the electrical panel breaker.

CONNECTIONS

Figure 3.3 Wall Mounting Options

Figure 3.3 Mounting of Base Unit

Table 3.1 Wiring Description for CM221

Figure 4.1 CX-ED2079 Strike Mounting

Figure 4.2 Mounting options for CX-ED2079

L4W 2T7

PERMISSION OF CAMDEN DOOR

CONTROLS IS PROHIBITED.

www.camdencontrols.com

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

CAMDEN DOOR CONTROLS. ANY

REPRODUCTION IN PART OR AS A

WHOLE WITHOUT THE WRITTEN

Tel: (905) 366-3377

5502 Timberlea Blvd.

Mississauga, ON Canada

Angelo

08/12/22

CM-753VR Column Switch

2 1/2'

'

[62.

0mm]

36''

[914.

3mm]

36''

[914.

3mm]

2 1/16'

'

[52.

1mm]

Floor

Acuat

or

Base

Unit

Insert

Screws

Mount

ing

Screw

Wall

Anchors

Top

Cap

Note:

While placing actuation bar back, make

sure that hanger sits perfectly into the slot.

D

C

B

A

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

NEXT ASSY

USED ON

APPLICATION

MATERIAL

DRAWN

CHECKED

ENG APPR.

MFG APPR.

Q.A.

COMMENTS:

DATE

NAME

TITLE:

SIZE

B

DWG. NO.

REV

SCALE: 1:1

UNLESS OTHERWISE SPECIFIED:

SHEET 1 OF 1

DO NOT SCALE DRAWING

DIMENSIONS ARE IN INCHES

TOLERANCES:

FRACTIONAL

± 1/64

ANGULAR: MACH

±0.5

BEND

±

TWO PLACE DECIMAL

± 0.010

THREE PLACE DECIMAL

± 0.005

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

CAMDEN DOOR CONTROLS. ANY

REPRODUCTION IN PART OR AS A

WHOLE WITHOUT THE WRITTEN

PERMISSION OF CAMDEN DOOR

CONTROLS IS PROHIBITED.

5502 Timberlea Blvd.

Mississauga, ON Canada

L4W 2T7

Tel: (905) 366-3377

www.camdencontrols.com

Hanger

Slot

End Cap

End Cap

Slot

Hanger