Pa

g

e

2

- M

an

u

al c

od

e:

11

9

G

3

13

6

11

9

G

3

13

6

ve

r.

2

0

3

/2

0

14 © C

A

M

E c

an

ce

lli auto

m

ati

ci s.p.a. - T

h

e d

ata a

n

d i

n

fo

rm

ati

on p

rovi

d

ed i

n th

is m

an

u

al a

re s

u

b

je

ct to c

h

an

g

e at a

ny ti

m

e w

ith

ou

t p

ri

or n

oti

ce by C

A

M

E C

an

ce

lli A

u

to

m

ati

ci S

.p.a.

ENGLISH

Foreword

• This product should only be used for the purpose for which it was explicitly

designed. Any other use is considered improper and therefore dangerous. CAME

Cancelli Automatici S.p.A. will not be held liable for damage caused by improper,

incorrect or unreasonable use. • The safety of the product, and therefore its pro-

per installation, depends on total compliance with the technical specifi cations and

installation procedures, as well as with rules regarding safety and use, expressly

mentioned in the technical documentation for the products themselves. • Keep

these warnings together with the installation and operation manuals for the ope-

rator system components.

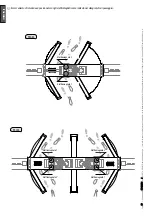

Before installing

(preliminary check: in case of a negative outcome, do not proceed until you have

complied with the safety requirements)

• Installation and testing must only be performed by qualifi ed personnel • Cable

routing, installation, connection and testing must be carried out to the highest

levels of workmanship in accordance with applicable laws and regulations • Be-

fore starting any operation, read all the instructions carefully; incorrect installation

can be dangerous and harm persons or property • Check that the operator is in

good mechanical condition, balanced and aligned, and that it opens and closes

properly. If needed, also install suitable guards or use appropriate additional safety

sensors • If the operator will be installed at a height of less than 2.5 m from the

ground or other access level, check whether you will need any protections and/or

warnings • Ensure that opening the turnstile does not create a dangerous situation

• Do not mount the operator upside down or onto any elements that may fold

under its weight. If needed, add suitable reinforcements at the points where it is

secured • Do not install on ground that is not level • Check that any lawn watering

devices will not wet the operator from the bottom up.

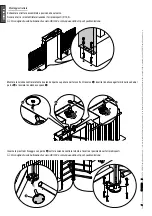

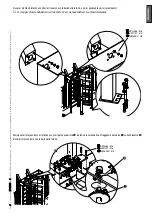

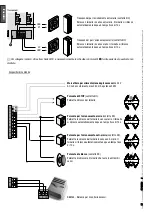

Installation

• Carefully section off the entire site to prevent unauthorised access, especially by

minors and children • Be careful when handling operators that weigh more than

20 kg. In such cases, use proper weight handling safety equipment • CE safety

devices (photocells, platforms, sensitive edges, emergency button etc.) must be

installed in compliance with applicable legislation and according to the highest

standards of workmanship, bearing in mind the environment, the type of service

required and the operating forces applied to the moving turnstiles. Points where

there is a risk of crushing, shearing or dragging must be protected using suitable

sensors • End users must be informed of any residual risks by means of special

pictograms as envisaged by legislation • All opening commands (buttons, key

selectors, magnetic readers etc.) must be installed at least 1.85 m from the pe-

rimeter of the area of turnstile movement, or where they cannot be reached from

outside through the turnstile. Also, the direct commands (buttons, touch comman-

ds etc.) must be installed at a height of at least 1.5 m and must not be accessible

to the public • The turnstile identifi cation data must be clearly visible • Before

connecting the turnstile to the power supply, make sure the identifi cation data

corresponds to the mains data • The turnstile must be connected to an eff ective,

compliant earthing system.

• The manufacturer disclaims any liability for the use of non-original products; this

also results in the invalidation of the warranty • All ‘hold-to-run’ commands must

be placed where the moving turnstile, transit areas and driveways are completely

visible • Before delivery to the user, check that the system complies with the EN

12453 and EN 12445 standards (impact tests), check that the operator has been

properly adjusted and that the safety and protective devices work correctly • As

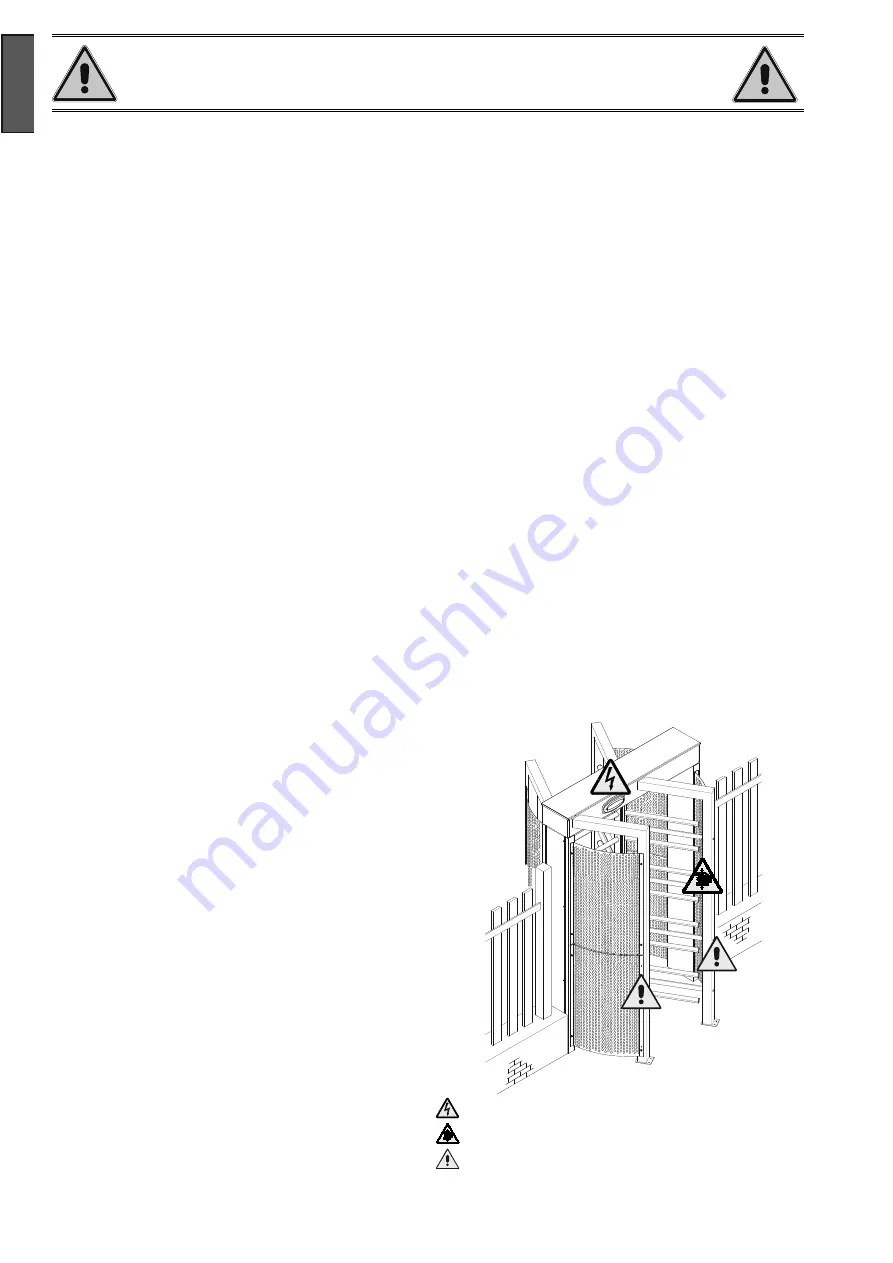

appropriate and in a visible position, affi x warning symbols.

Special instructions and advice for users

• Keep the turnstile’s area of operation clean and clear of any obstacles. Check

that the photocells' area of operation is free from obstacles • Children must be

supervised to make sure they do not play with the operator and the fi xed control

CAUTION!

important personal safety instructions:

READ CAREFULLY!

Danger of hand crushing

Danger - live parts

Warning Impact Hazard

devices or stand in the turnstile's area of operation. Keep any remote control devi-

ces (i.e. transmitters) or any control devices away from children as well, to prevent

the operator from being activated accidentally • The operator is not designed

to be used by persons (including children) whose physical, sensorial or mental

capacities are limited, or who are lacking in experience or knowledge, unless said

persons can be supervised or given instructions regarding using the operator by a

person responsible for their safety • Frequently check the system, to see whether

any anomalies or signs of wear and tear appear on the moving parts, on the com-

ponent parts, on the securing points, on the cables and any accessible connec-

tions. Keep any joints lubricated and clean, and do the same where friction may

occur • Perform functional tests on photocells every six months. Ensure that the

glass on the photocells is kept clean (use a cloth slightly moistened with water; do

not use solvents or any other chemicals as these could damage the devices) • If

the system requires repairs or modifi cations, disconnect the power to the operator

and do not use it until safety conditions have been restored • Cut off the electrical

power supply for manual opening. Read the instructions • If the power cable is

damaged, it must be replaced by the manufacturer or the technical assistance

service or by a person with a similar qualifi cation so as to prevent any risks • It is

STRICTLY FORBIDDEN for users to perform OPERATIONS THEY ARE NOT EXPLI-

CITLY REQUIRED AND ASKED to do. For repairs, adjustments and extraordinary

maintenance, CONTACT THE SPECIALIST TECHNICAL SERVICE CENTRE. On the

periodic maintenance log, note down the checks you have done.

Further special instructions and advice for all

• Avoid working near the turnstiles or moving mechanical parts • Stay clear of the

turnstile's area of operation when in motion • Do not resist the direction of move-

ment of the operator; this may present a safety hazard • At all times be extremely

careful about dangerous points that must be indicated by proper pictograms and/

or black and yellow stripes • When using a selector or command in ‘hold-to-run’

mode, keep checking that there are no people in the area of operation of the

moving parts. Do this until you release the command • The turnstile may move

at any time without warning • Always cut the power when cleaning or performing

maintenance.