Pa

g

e

1919

-

M

an

u

al c

od

e:

11

9

G

3

13

6

11

9

G

3

13

6

ve

r.

2

0

3

/2

0

14

© C

A

M

E c

an

ce

lli auto

m

ati

ci s.p.a. - T

h

e d

ata a

n

d i

n

fo

rm

ati

on p

rovi

d

ed i

n th

is m

an

u

al a

re s

u

b

je

ct to c

h

an

g

e at a

ny ti

m

e w

ith

ou

t p

ri

or n

oti

ce by C

A

M

E C

an

ce

lli A

u

to

m

ati

ci S

.p.a.

ENGLISH

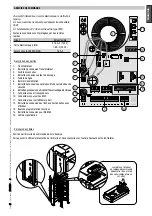

Troubleshooting

PROBLEM

POSSIBLE CAUSES

CHECKS AND REMEDIES

The turnstile remains

unlocked in both directions

• No power

• Emergency or release button pressed

• Electric locks out of order

• Check for mains power

• Reset the emergency button or release button

• Contact service

The turnstile unlocks only in

one direction

• One of the electric locks is out of order

• The spring of one of the electric locks has come

unlatched

• Button 2-3 or 2-4 is pressed

• Contact service

• Restore the spring

• Check the contact

The turnstile remains locked • The person going through leaned on the arm too

early.

• Both electric locks remain energised

• The stop button is active

• Ask the person to stand free of the arm and try

unlocking again

• Contact service

• Check the release command validity

The turnstile fails to

slowdown at end run

• The hydraulic damper is out of order

• Adjust the hydraulic damper

The turnstile remains

unlocked after passing

through it

The entrance/exit sensor is positioned incorrectly

The entrance/exit sensor is out of order

Check the position of the entrance/exit sensor

Contact service

•

Every 400,000 cycles and at least every 6 months:

• Check turnstile internal wiring and verify that there are no

loose or damaged cables.

• Check that there are no abnormal movements and that

rotation is smooth by turning the turnstile. Any sudden

locking could be a sign of malfunction.

• Check that turnstile is securely fixed to the ground by trying

to move it; poor ground anchoring could lead to danger.

• Check bolt tightness.

• Check hydraulic damper adjustment.

• Check the efficiency of lock/release levers.

• Linear rail cleaning/lubrication.

• Check roller condition.

•

Each 1,000,000 cycles, replace:

• Rollers and electric locks.

•

Each 3,000,000 cycles, replace:

• Runner springs.

Periodic maintenance

DISMANTLING AND DISPOSAL

CAME CANCELLI AUTOMATICI S.p.A. implements an EN ISO 14001 certified and compliant Environmental Management System at its

plants, to ensure environmental protection.

Please continue our efforts to protect the environment, something that CAME considers to be one of the foundations in developing its

business and market strategies, simply by observing brief recommendations as regards disposal:

DISPOSAL OF PACKAGING

Packaging components (cardboard, plastic, etc.) can be disposed of together with normal household waste without any difficulty, by simply

separating the different types of waste and recycling them.

Before proceeding, it is always advisable to check specific regulations in force in the place of installation.

DISPOSE OF PROPERLY!

DISPOSAL OF THE PRODUCT

Our products are made with different materials. Most of them (aluminium, plastic, iron, electrical cables) can be disposed of together with

normal household waste. They can be recycled if collected, sorted and sent to authorised centres.

Other components (control boards, transmitter batteries etc.), on the other hand, may contain pollutants. They should therefore be removed

and handed over to companies authorised to recover and recycle them.

Before proceeding, it is always advisable to check specific regulations in force in the place of disposal.

DISPOSE OF PROPERLY!

DECLARATION OF CONFORMITY

Declaration - Came Cancelli Automatici S.p.A. declares that this device complies with the essential requirements and other relevant

provisions established in Directives 2006/95/EC and

2014/30/UE.

A true copy of the declaration of conformity is available upon request.