6

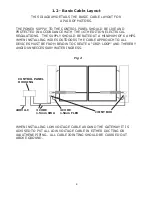

THE REAR BRACKET IS EQUIPPED WITH ADDITIONAL HOLES TO MAKE

INSTALLATION OF THE GATE MOTOR EASIER, OR TO CHANGE THE

OPENING ANGLE OF THE GATE. THE REAR BRACKET CAN BE LENGHENED

OR SHORTENED TO SUIT THE INDIVIDUAL INSTALLATION SITE AND THE

POSITION OF THE GATES (WITH RESPECT TO THE PILLARS).

N.B

IF MEASUREMENT

B

IS INCREASED, THE ANGLE OF APETURE IS

REDUCED. THIS THEREFORE REDUCES THE PERIPHERAL SPEED

AND INCREASES THE THRUST EXERTED BY THE MOTOR ON THE

GATE. IF MEASUREMENT

A

IS INCREASED, THE ANGLE OF

APERTURE IS INCREASED. THIS THEREFORE INCREASES THE

PERIPHERAL SPEED AND REDUCES THE THRUST EXERTED BY THE

MOTOR ON THE GATE.

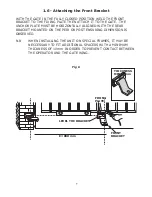

WHEN THE REAR BRACKET IS SECURELY ATTACHED TO THE PIER OR POST,

INSERT THE BUSH INTO THE DESIRED HOLE AND ATTACH THE REAR JOINT

ARM, LUBRICATING WITH A NEUTRAL GREASE.

Fig 5

MB

REAR JOINT

M8 X 38

BUSHING

1.5 - Attaching the Rear Bracket

Summary of Contents for ATI KIT

Page 33: ...Notes ...

Page 34: ...Notes ...

Page 35: ...Notes ...

Page 36: ...6 INFORMATION THIS INSTALLATION WAS COMPLETED BY NAME ADDRESS TEL MOBILE DATE OF INSTALLATION ...