p.

2

- M

an

u

al

:

F

A

0

0

6

0

5

-E

N

FA

0

0

6

0

5

-E

N

v.

1

- 0

1/

2

0

17 - © C

A

M

E S

.p.

A

. - T

h

e c

onte

nts of th

is

m

an

u

al

m

ay b

e c

h

an

g

ed, at a

ny ti

m

e, a

n

d w

ith

ou

t n

oti

ce

.

P

REMISE

• T

HIS

PRODUCT

SHOULD

ONLY

BE

USED

FOR

THE

PURPOSE

FOR

WHICH

IT

WAS

EXPLICITLY

DESIGNED

. A

NY

OTHER

USE

IS

DANGEROUS

.

CAME S.

P

.A.

IS

NOT

LIABLE

FOR

ANY

DAMAGE

CAUSED

BY

IMPROPER

,

WRONGFUL

AND

UNREASONABLE

USE

• K

EEP

THESE

WARNINGS

TOGETHER

WITH

THE

INSTALLATION

AND

OPERATION

MANUALS

THAT

COME

WITH

THE

OPERATOR

.

B

EFORE

INSTALLING

(

CHECKING

WHAT

'

S

THERE

:

IF

SOMETHING

IS

MISSING

,

DO

NOT

CONTINUE

UNTIL

YOU

HAVE

COMPLIED

WITH

ALL

SAFETY

PROVISIONS

)

• C

HECK

THAT

THE

AUTOMATED

PARTS

ARE

IN

PROPER

MECHANICAL

ORDER

,

THAT

THE

OPERATOR

IS

LEVEL

AND

ALIGNED

,

AND

THAT

IT

OPENS

AND

CLOSES

PROPERLY

.

M

AKE

SURE

YOU

HAVE

SUITABLE

MECHANICAL

STOPS

• I

F

THE

OPERATOR

IS

TO

BE

INSTALLED

AT

A

HEIGHT

OF

LESS

THAN

2.5

M

FROM

THE

GROUND

OR

OTHER

ACCESS

LEVEL

,

MAKE

SURE

YOU

HAVE

ANY

NECESSARY

PROTECTIONS

AND

/

OR

WARNINGS

IN

PLACE

• I

F

ANY

PEDESTRIAN

OPENINGS

ARE

FITTED

INTO

THE

OPERATOR

,

THERE

MUST

ALSO

BE

A

A

SYSTEM

TO

BLOCK

THEIR

OPENING

WHILE

THEY

ARE

MOVING

•

M

AKE

SURE

THAT

THE

OPENING

AUTOMATED

DOOR

OR

GATE

CANNOT

ENTRAP

PEOPLE

AGAINST

THE

FIXED

PARTS

OF

THE

OPERATOR

• D

O

NOT

FIT

UPSIDE

DOWN

OR

ONTO

ELEMENTS

THAT

COULD

BEND

. I

F

NECESSARY

,

ADD

SUITABLE

REINFORCEMENTS

TO

THE

ANCHORING

POINTS

• D

O

NOT

INSTALL

DOOR

OR

GATE

LEAVES

ON

TILTED

SURFACES

• M

AKE

SURE

ANY

SPRINKLER

SYSTEMS

CANNOT

WET

THE

OPERATOR

FROM

THE

GROUND

UP

• M

AKE

SURE

THE

TEMPERATURE

RANGE

SHOWN

ON

THE

PRODUCT

LITERATURE

IS

SUITABLE

TO

THE

CLIMATE

WHERE

IT

WILL

BE

INSTALLED

• F

OLLOW

ALL

INSTRUCTIONS

AS

IMPROPER

INSTALLATION

MAY

RESULT

IN

SERIOUS

BODILY

INJURY

•

I

T

IS

IMPORTANT

TO

FOLLOW

THESE

INSTRUCTIONS

FOR

THE

SAFETY

OF

PEOPLE

. K

EEP

THESE

INSTRUCTIONS

.

I

NSTALLING

• S

UITABLY

SECTION

OFF

AND

DEMARCATE

THE

ENTIRE

INSTALLATION

SITE

TO

PREVENT

UNAUTHORIZED

PERSONS

FROM

ENTERING

THE

AREA

,

ESPECIALLY

MINORS

AND

CHILDREN

• B

E

CAREFUL

WHEN

HANDLING

OPERATORS

THAT

WEIGH

OVER

20

KG

.

I

F

NEED

BE

,

USE

PROPER

SAFETY

HOISTING

EQUIPMENT

• A

LL

OPENING

COMMANDS

(

THAT

IS

,

BUTTONS

,

KEY

SWITCHES

,

MAGNETIC

READERS

,

AND

SO

ON

)

MUST

BE

INSTALLED

AT

LEAST

1.85

M

FROM

THE

PERIMETER

OF

THE

GATE

'

S

WORKING

AREA

,

OR

WHERE

THEY

CANNOT

BE

REACHED

FROM

OUTSIDE

THE

GATE

. A

LSO

,

ANY

DIRECT

COMMANDS

(

WHETHER

BUTTONS

,

TOUCH

PANELS

,

AND

SO

ON

)

MUST

BE

INSTALLED

AT

LEAST

1.5

M

FROM

THE

GROUND

AND

MUST

NOT

BE

REACHABLE

BY

UNAUTHORIZED

PERSONS

• A

LL

MAINTAINED

ACTION

COMMANDS

,

MUST

BE

FITTED

IN

PLACES

FROM

WHICH

THE

MOVING

GATE

LEAVES

AND

TRANSIT

AND

DRIVING

AREAS

ARE

VISIBLE

•

A

PPLY

,

IF

MISSING

,

A

PERMANENT

SIGN

SHOWING

THE

POSITION

OF

THE

RELEASE

DEVICE

• B

EFORE

DELIVERING

TO

THE

USERS

,

MAKE

SURE

THE

SYSTEM

IS

EN

12453

STANDARD

COMPLIANT

(

REGARDING

IMPACT

FORCES

),

AND

ALSO

MAKE

SURE

THE

SYSTEM

HAS

BEEN

PROPERLY

ADJUSTED

AND

THAT

ANY

SAFETY

,

PROTECTION

AND

MANUAL

RELEASE

DEVICES

ARE

WORKING

PROPERLY

• A

PPLY

W

ARNING

S

IGNS

WHERE

NECESSARY

AND

IN

A

VISIBLE

PLACE

, (

SUCH

AS

,

SUCH

AS

THE

GATE

'

S

PLATE

S

PECIAL

USER

-

INSTRUCTIONS

AND

RECOMMENDATIONS

• K

EEP

GATE

OPERATION

AREAS

CLEAN

AND

FREE

OF

ANY

OBSTRUCTIONS

. M

AKE

SURE

THAT

THE

PHOTOCELLS

ARE

FREE

OF

ANY

OVERGROWN

VEGETATION

AND

THAT

THE

OPERATOR

'

S

AREA

OF

OPERATION

IS

FREE

OF

ANY

OBSTRUCTIONS

• D

O

NOT

ALLOW

CHILDREN

TO

PLAY

WITH

FIXED

COMMANDS

,

OR

TO

LOITER

IN

THE

GATE

'

S

MANEUVERING

AREA

. K

EEP

ANY

REMOTE

CONTROL

TRANSMITTERS

OR

ANY

OTHER

COMMAND

DEVICE

AWAY

FROM

CHILDREN

,

TO

PREVENT

THE

OPERATOR

FROM

BEING

ACCIDENTALLY

ACTIVATED

. • T

HE

APPARATUS

MAY

BE

USED

BY

CHILDREN

OF

EIGHT

YEARS

AND

ABOVE

AND

BY

PHYSICALLY

,

MENTALLY

AND

SENSORY

-

CHALLENGED

PEOPLE

,

OR

EVEN

ONES

WITHOUT

ANY

EXPERIENCE

,

PROVIDED

THIS

HAPPENS

UNDER

CLOSE

SUPERVISION

OR

ONCE

THEY

HAVE

BEEN

PROPERLY

INSTRUCTED

TO

USE

THE

APPARATUS

SAFELY

AND

TO

THE

POTENTIAL

HAZARDS

INVOLVED

. C

HILDREN

MUST

NOT

PLAY

WITH

THE

APPARATUS

. C

LEANING

AND

MAINTENANCE

BY

USERS

MUST

NOT

BE

DONE

BY

CHILDREN

,

UNLESS

PROPERLY

SUPERVISED

• F

REQUENTLY

CHECK

THE

SYSTEM

FOR

ANY

MALFUNCTIONS

OR

SIGNS

OF

WEAR

AND

TEAR

OR

DAMAGE

TO

THE

MOVING

STRUCTURES

,

TO

THE

COMPONENT

PARTS

,

ALL

ANCHORING

POINTS

,

INCLUDING

CABLES

AND

ANY

ACCESSIBLE

CONNECTIONS

. K

EEP

ANY

HINGES

,

MOVING

JOINTS

AND

SLIDE

RAILS

PROPERLY

LUBRICATED

• P

ERFORM

FUNCTIONAL

CHECKS

ON

THE

PHOTOCELLS

AND

SENSITIVE

SAFETY

EDGES

,

EVERY

SIX

MONTHS

. T

O

CHECK

WHETHER

THE

PHOTOCELLS

ARE

WORKING

,

WAVE

AN

OBJECT

IN

FRONT

OF

THEM

WHILE

THE

GATE

IS

CLOSING

;

IF

THE

OPERATOR

INVERTS

ITS

DIRECTION

OF

TRAVEL

OR

SUDDENLY

STOPS

,

THE

PHOTOCELLS

ARE

WORKING

PROPERLY

. T

HIS

IS

THE

ONLY

MAINTENANCE

OPERATION

TO

DO

WITH

THE

POWER

ON

. C

ONSTANTLY

CLEAN

THE

PHOTOCELLS

'

GLASS

COVERS

USING

A

SLIGHTLY

WATER

-

MOISTENED

CLOTH

;

DO

NOT

USE

SOLVENTS

OR

OTHER

CHEMICAL

PRODUCTS

THAT

MAY

RUIN

THE

DEVICES

• I

F

REPAIRS

OR

MODIFICATIONS

ARE

REQUIRED

TO

THE

SYSTEM

,

RELEASE

THE

OPERATOR

AND

DO

NOT

USE

IT

UNTIL

SAFETY

CONDITIONS

HAVE

BEEN

RESTORED

• C

UT

OFF

THE

POWER

SUPPLY

BEFORE

RELEASING

THE

OPERATOR

FOR

MANUAL

OPENINGS

AND

BEFORE

ANY

OTHER

OPERATION

,

TO

PREVENT

POTENTIALLY

HAZARDOUS

SITUATIONS

.

R

EAD

THE

INSTRUCTIONS

I

F

THE

POWER

SUPPLY

CABLE

IS

DAMAGED

,

IT

MUST

BE

REPLACED

BY

THE

MANUFACTURER

OR

AUTHORIZED

TECHNICAL

ASSISTANCE

SERVICE

,

OR

IN

ANY

CASE

,

BY

SIMILARLY

QUALIFIED

PERSONS

,

TO

PREVENT

ANY

RISK

• I

T

IS

FORBIDDEN

FOR

USERS

TO

PERFORM

ANY

OPERATIONS THAT ARE NOT

EXPRESSLY REQUIRED OF THEM AND WHICH ARE NOT LISTED

IN

THE

MANUALS

. F

OR

ANY

REPAIRS

,

MODIFICATIONS

/

ADJUSTMENTS

,

AND

FOR

EXTRA

-

ORDINARY

MAINTENANCE

, CALL TECHNICAL ASSISTANCE • L

OG

THE

JOB

AND

CHECKS

INTO

THE

PERIODIC

MAINTENANCE

LOG

.

F

URTHER

RECOMMENDATIONS

FOR

ALL

• K

EEP

CLEAR

OF

HINGES

AND

MECHANICAL

MOVING

PARTS

• D

O

NOT

ENTER

THE

OPERATOR

'

S

AREA

OF

OPERATION

WHEN

IT

IS

MOVING

• D

O

NOT

COUNTER

THE

OPERATOR

'

S

MOVEMENT

AS

THIS

COULD

RESULT

IN

DANGEROUS

SITUATIONS

• A

LWAYS

PAY

SPECIAL

ATTENTION

TO

ANY

DANGEROUS

POINTS

,

WHICH

HAVE

TO

BE

LABELED

WITH

SPECIFIC

PICTOGRAMS

AND

/

OR

BLACK

AND

YELLOW

STRIPES

• W

HILE

USING

A

SELECTOR

SWITCH

OR

A

COMMAND

IN

MAINTAINED

ACTIONS

,

KEEP

CHECKING

THAT

THERE

ARE

NO

PERSONS

WITHIN

THE

OPERATING

RANGE

OF

ANY

MOVING

PARTS

,

UNTIL

THE

COMMAND

IS

RELEASED

• T

HE

GATE

MAY

MOVE

AT

ANY

TIME

AND

WITHOUT

WARNING

• A

LWAYS

CUT

OFF

THE

MAINS

POWER

SUPPLY

BEFORE

PERFORMING

ANY

MAINTENANCE

OR

CLEANING

.

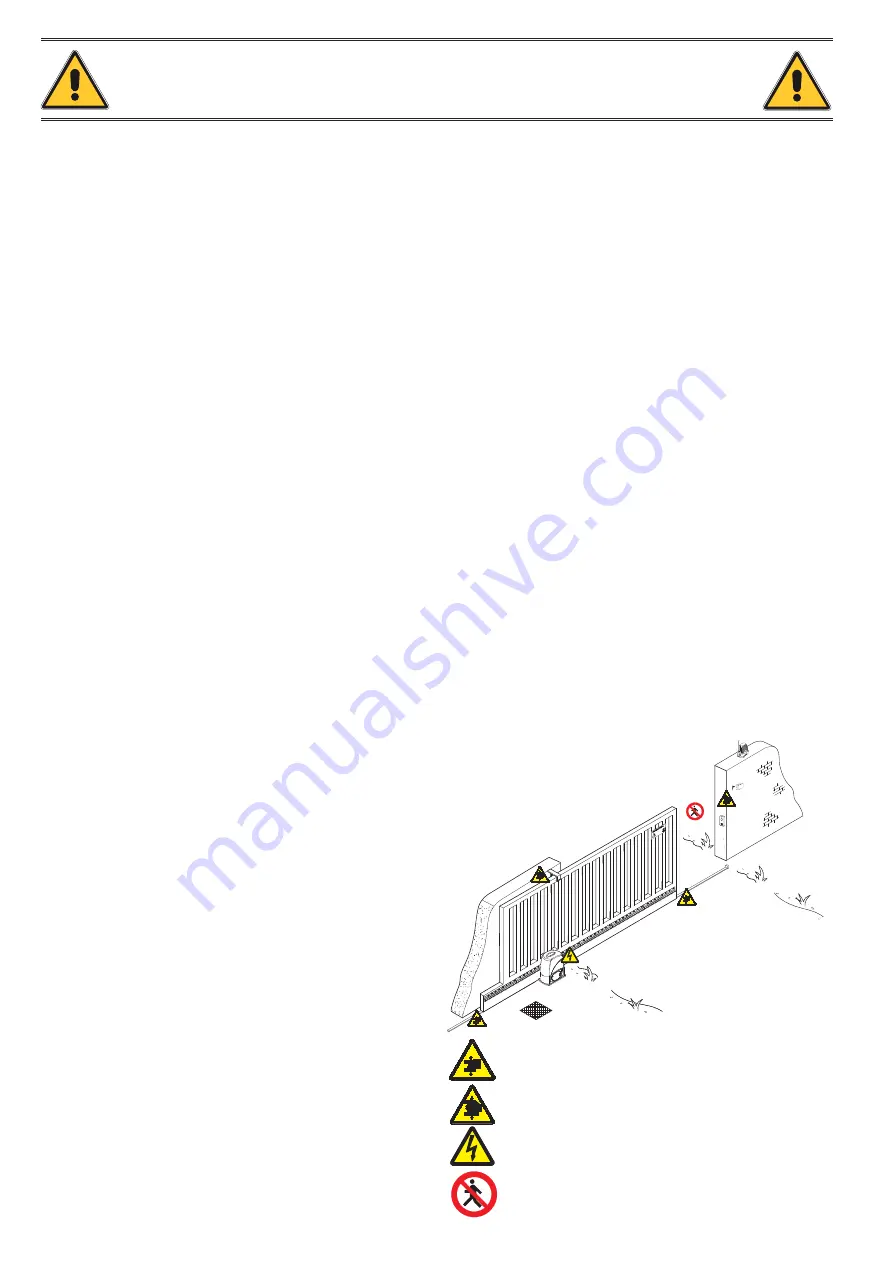

WARNING!

important safety instructions for people:

READ CAREFULLY!

Danger of hand crushing

Danger! High voltage.

No transiting while the barrier is moving

Danger of foot crushing