Page

19

- Manual

FA01295-EN

- 03/2023 - © C

AME S.p.A. - The contents of this manual may be changed at any time and without notice. - T

ranslation of the o

riginal instructions

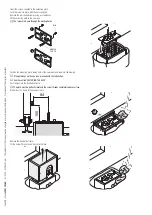

Power supply output for accessories

10 11 TS 1

24V 0

The output normally delivers 24 V AC.

The sum of the power draw for the connected accessories must not exceed 20 W.

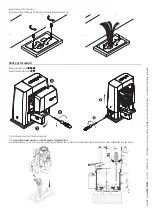

Torque limiter

L1T L2T CT VS VF

24V 0

0

17

24

FR

1

2

3

4

SP

0

1

2

3

4

5

8

7

6

1

Grey cable

2

Brown cable

3

Red cable

4

Black cable

5

White cable

6

To vary the motor torque, move the corresponding Faston terminal to

one of the four positions; from 1 (minimum) to 4 (maximum).

7

Blue cable

8

Orange cable

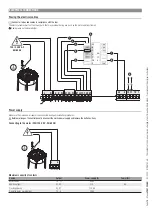

Signalling devices

1

Flashing beacon

It flashes when the operator opens and closes.

2

Additional light

It increases the light in the manoeuvring area.

See function [F18].

3

Passage-open warning light

It notifies the user of the operator status.

See function [F10].

2

1

3

L

N

U V W

E1 EX W

24V

O

10 11 TS 1

2

3 3P 4

5

7 CX CY

L1T L2T CT VS VF

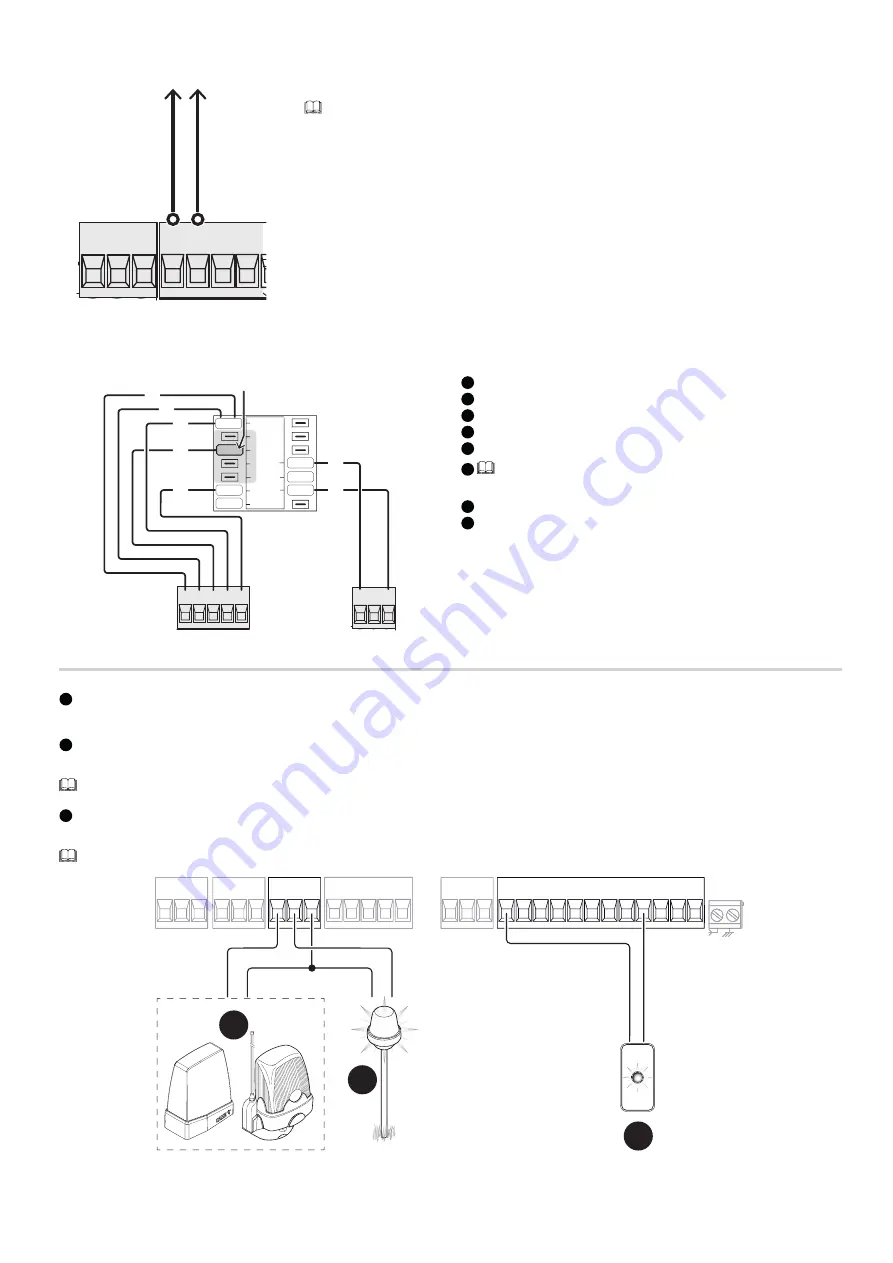

L

N

U V W

24V

O

L1T L2T CT VS VF