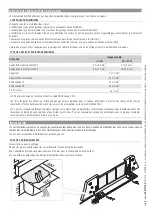

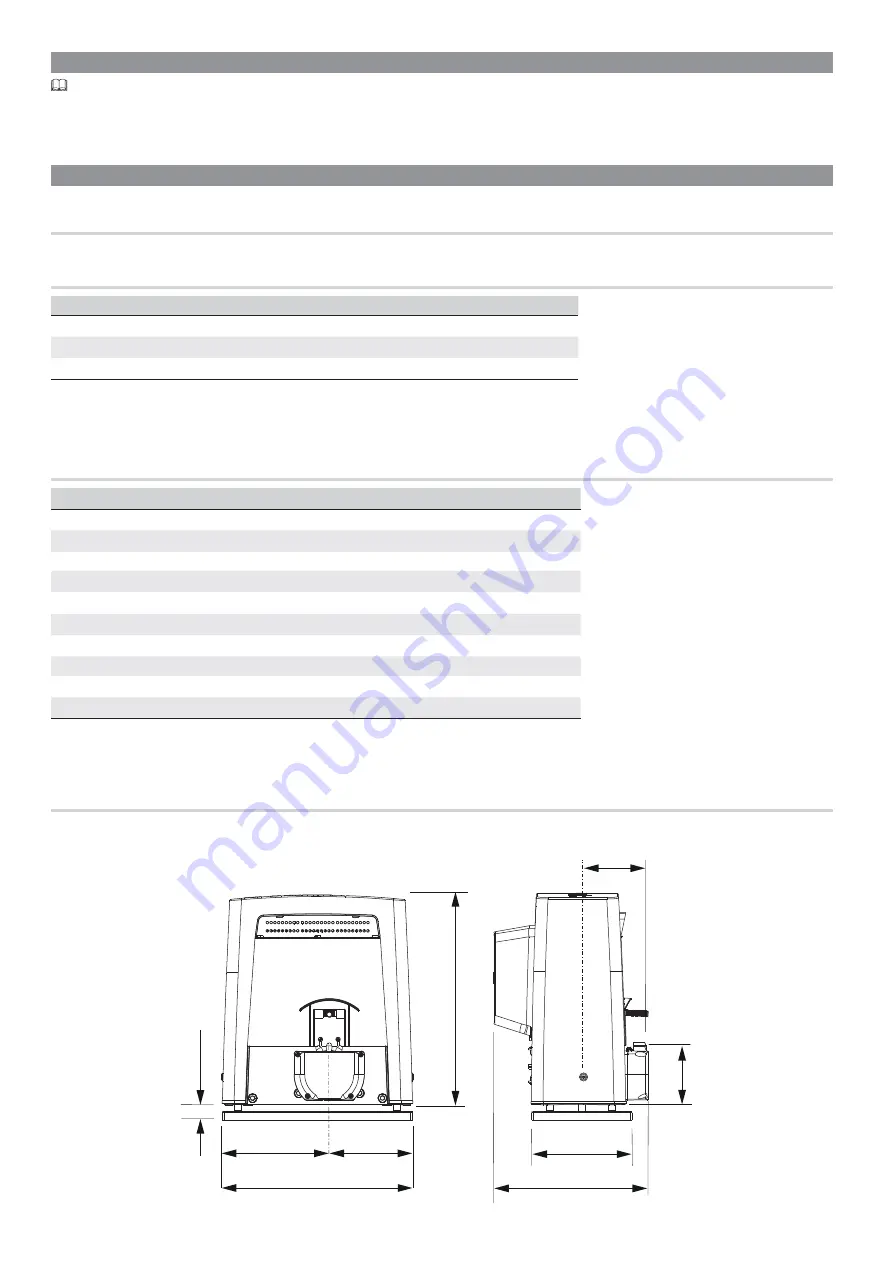

183

143

326

22 max.

359,5

105

106

170

262

Стр.

4

— Руково

дство

FA01157-RU

—09/2018 — © CAME S.p.A. — Со

держание данног

о руково

дства може

т быть изменено в любое время без пре

дварит

ельног

о уве

домления.

— Перево

д оригинальных инструкций

УСЛОВНЫЕ ОБОЗНАЧЕНИЯ

Этот символ обозначает раздел, требующий особого внимания.

⚠

Этот символ обозначает раздел, связанный с вопросами безопасности.

☞

Этот символ обозначает раздел, предназначенный для ознакомления конечного пользователя.

Все размеры приведены в мм, если не указано иное.

ГАБАРИТНЫЕ РАЗМЕРЫ

ОПИСАНИЕ

Привод для откатных ворот массой до 2200 кг и длиной до 23 м.

НАЗНАЧЕНИЕ

Привод предназначен для автоматизации откатных ворот, установленных на жилых и промышленных объектах.

ОГРАНИЧЕНИЯ В ИСПОЛЬЗОВАНИИ

Модель

BKS22TGS

Относительная стандартная длина* подвижной части (м)

10

Максимальная масса подвижной части (кг)

2 200

Модуль шестерни

6

* При использовании с воротами нестандартных размеров смотрите следующие графики.

ТЕХНИЧЕСКИЕ ХАРАКТЕРИСТИКИ

Модель

BKS22TGS

Класс защиты (IP)

44

Напряжение питания (В, 50/60 Гц)

~230/400, ТРИ ФАЗЫ

Электропитание мотора (В) (50/60 Гц)

~230/400, ТРИ ФАЗЫ

Мощность (Вт)

520

Толкающее усилие (Н)

1650

Рабочая скорость (м/мин)

10,5

Диапазон рабочих температур (°C)

от –20 до +55

Класс устройства

I

Термозащита мотора (°C)

150

Масса (кг)

21

Стр.

4

— Руково

дство

FA01157-RU

— 09/2018 — © CAME S.p.A. — Со

держание данног

о руково

дства може

т быть изменено в любое время без пре

дварит

ельног

о уве

домления.

— Oригинальных инструкций

Summary of Contents for BKS22TGS

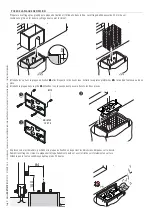

Page 2: ...2 3 1 2 3 1...

Page 17: ...EN English FA01157 EN Sliding gate operator BKS22TGS INSTALLATION MANUAL...

Page 18: ...2 3 1 2 3 1...

Page 33: ...Automatisme pour portails coulissants BKS22TGS MANUEL D INSTALLATION FR Fran ais FA01157 FR...

Page 34: ...2 3 1 2 3 1...

Page 49: ...BKS22TGS RU FA01157 RU...

Page 50: ...2 3 1 2 3 1...

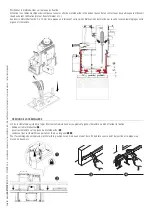

Page 56: ...8 FA01157 RU 09 2018 CAME S p A 600 8 FA01157 RU 09 2018 CAME S p A O...

Page 57: ...5 10 9 FA01157 RU 09 2018 CAME S p A 5 10 9 FA01157 RU 09 2018 CAME S p A O...

Page 58: ...1 2 10 FA01157 RU 09 2018 CAME S p A 10 FA01157 RU 09 2018 CAME S p A O...

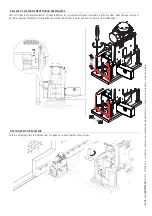

Page 59: ...1 2 2 2 1 11 FA01157 RU 09 2018 CAME S p A 20 20 11 FA01157 RU 09 2018 CAME S p A O...

Page 63: ...15 FA01157 RU 09 2018 CAME S p A 15 FA01157 RU 09 2018 CAME S p A O...