7

7

7

7

Page

5

- Manual

FA01157-EN

- 09/2018 - © CAME S.p.A. - The contents of this manual may be changed, at any time, and without notice. - T

ranslation of the

original instructions

DUTY CYCLES

Datum

Cycles/hour (no.)

14 series

Consecutive cycles (no.)

17 series

The cycles calculation is for

standard-length gates

(see the intended use), that are professionally installed, free of any mechanical issues and/or accidental

friction points, and measured at 20° C, as stated in EN Standard 60335-2-103.

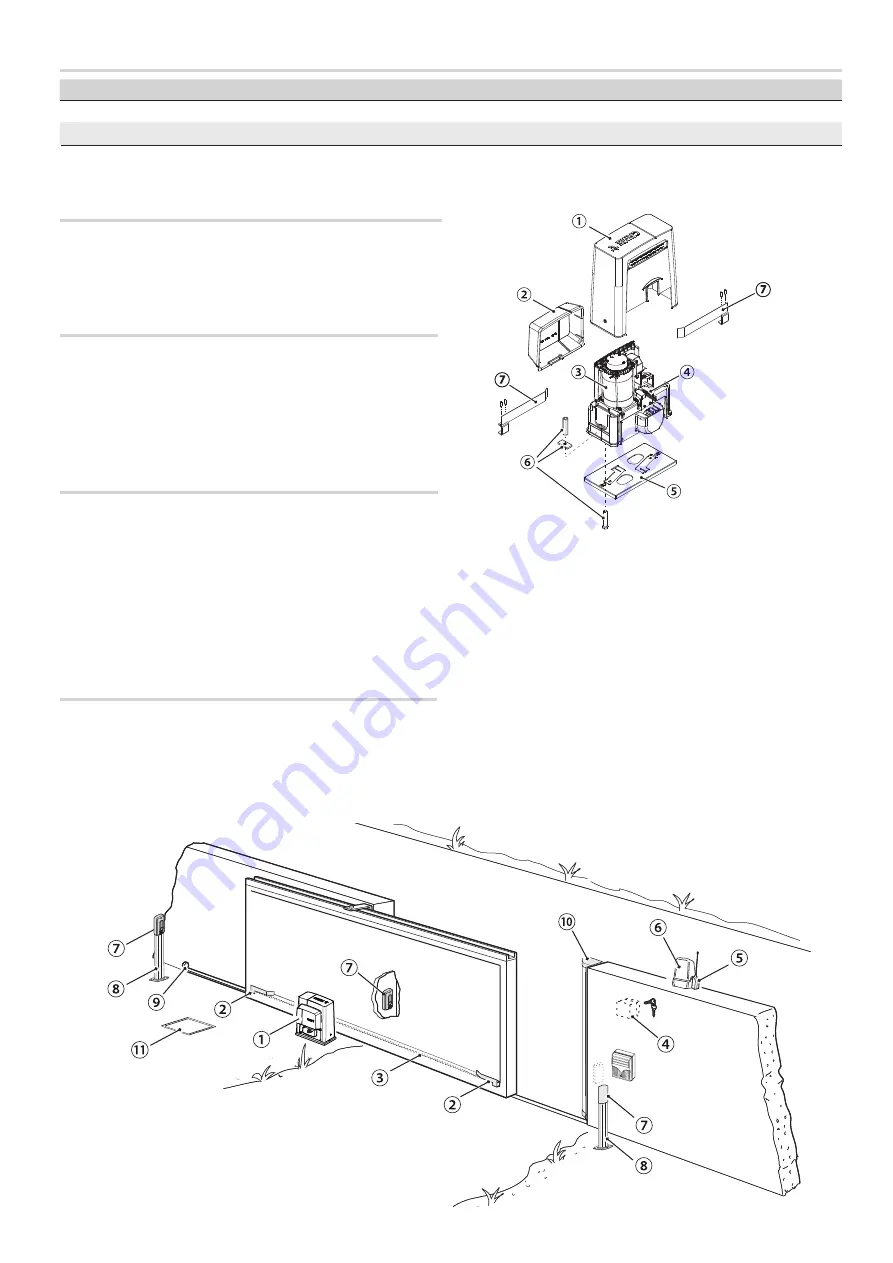

DESCRIPTION OF PARTS

1. Cover

2. Front

cover

3. Gearmotor

4. Mechanical limit switch

5. Anchoring

plate

6.

Fastening

hardware

7. Limit-switch

tabs

STANDARD INSTALLATION

1. Gearmotor

2. Limit-switch

fins

3. Rack

4. Key-switch

selector

5. Antenna(s)

6. Flashing

light

7. Photocells

8. Small

post

9. Mechanical gate stop

10. Sensitive safety-edge

11. Junction pit

CONTROL PANELS

002ZT6

Control panel with safety devices self-diagnosis.

002ZT6C

Control panel, complete with safety lock and buttons, with safety

devices self-diagnosis.

COMPLETION ACCESSORIES

❶

001B4353

Chain transmission device.

❷

009CCT

Simple 1/2” chain.

❸

009CGIU

1/2” chain coupling.

❹

001R001

Customized cylinder lock.

Page

5

- Manual

FA01

22

9-EN

- 10/2018 - © CAME S.p.A. - The contents of this manual may be changed, at any time, and without notice. - Original instructio

ns